Anti bird spike is a device to drive away birds. It is mostly made of stainless steel and other materials, with a spiked appearance. SS304 Birds Control Deterrent Spikes prevent birds from staying or nesting on building windowsills, eaves, billboards, etc., through physical barriers, thereby avoiding noise, feces, and damage to facilities. It is widely used in urban construction and agriculture. Wanzhi Steel is a professional manufacturer of anti-bird spikes. We have a large number of common specifications in stock, and we accept customized sizes and direct sales prices. Don’t hesitate to get in touch with us to learn more.

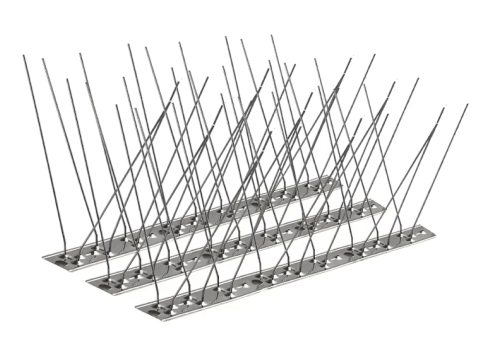

SS anti pigeon spikes

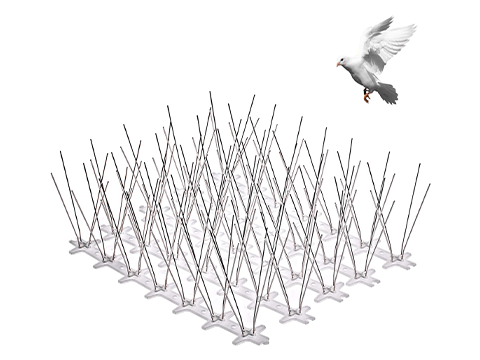

pigeon proofing spikes

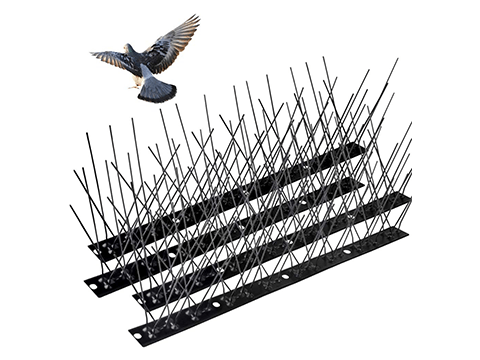

black bird proof spike

Anti bird spike Specification

| Item | Anti bird spike(bird-proof spikes) |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Material | 304/316 Stainless Steel+PC |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Use | Lawn, farm, home & perimeter, yards |

| Pest type | Birds, cats, pigeons, and snakes |

| Type | 2-2-2-2 ( 40spikes ), 2-4-2-4 ( 60spikes ), As customer’s request |

| State | Solid |

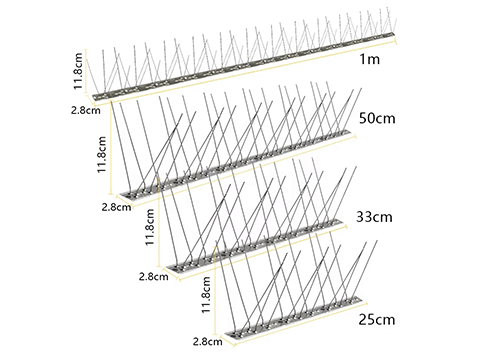

| Length | 25 cm- 100 cm, as per the customer’s request |

| Width | As the customer’s request |

| Spike length | As the customer’s request |

| Number of spikes | 12-48 spikes |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Available |

| Price Item | FOB, CIF, EXW, etc |

| Packing | Carton |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5000 PCs, 5 tons |

| Transportation | By sea, by land |

What are Anti bird Spikes?

Bird-proof spikes (also known as anti perching /anti nesting /anti pigeon, or anti roosting spikes) are physical bird-repellent devices consisting of rows of upward-pointing stainless steel or polycarbonate spikes. They are installed on high-altitude structures such as building roofs, window sills, signboards, bridges, signal towers, etc. Their function is to prevent birds such as pigeons, crows, and seagulls from perching, nesting, or defecating by creating sharp surfaces that birds cannot stay on. When used on window sills and eaves, it can also prevent the invasion of cats, mice, squirrels, raccoons, etc. They are corrosion-resistant, anti-aging, and easy to install, making them an environmentally friendly, long-lasting, and bird-friendly solution.

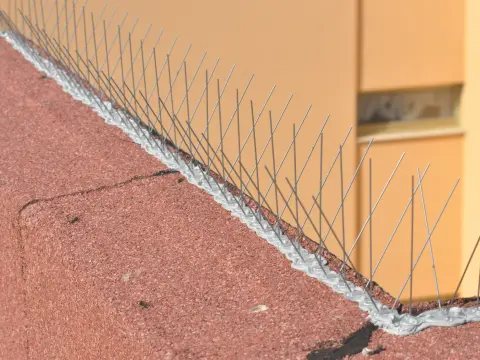

Roof applications

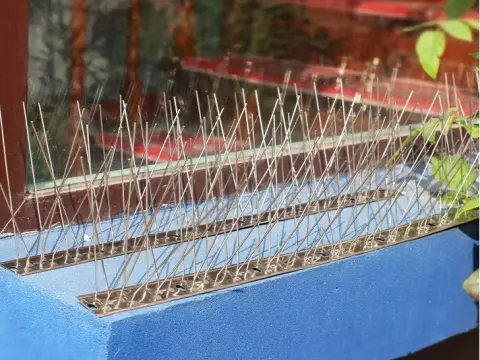

Window sill bird protection spikes

Parking lot fence top

Main Features

(1) Efficient bird prevention: The densely arranged steel spikes form a physical barrier, directly preventing birds from staying or nesting on the surface of the equipment, and the bird prevention effect is significant.

(2) Flexible structure: Some use retractable or bendable steel spikes, and the adjustable design can adjust the angle and coverage according to the environment.

(3) Strong durability: It uses corrosion-resistant materials such as stainless steel and galvanized steel to adapt to long-term outdoor wind, sun, rain, etc., and has a long service life. The steel spike structure is stable and not easily deformed or damaged by strong winds, ensuring long-term protection.

(4) Convenient installation: It is fixed by buckles, screws or binding methods, supports multiple groups of splicing, can cover a large area, and does not require complex tools. One person can complete the installation.

(5) Strong compatibility: It can be adapted to a variety of carriers such as power line insulators, building beams, roof edges, etc., without destroying the original structure.

(6) Low cost: Bird-proof spike materials are low cost, simple to maintain, and have significant long-term benefits compared with bird repellents, power grids, and other equipment.

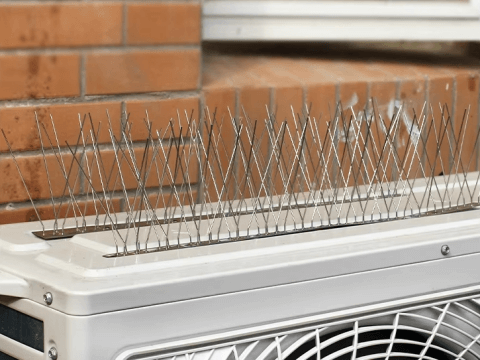

Air conditioner outdoor unit use

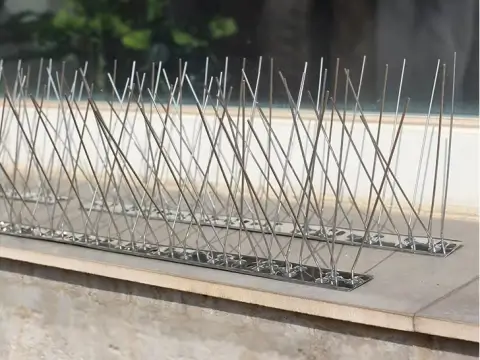

Bird-proof spikes on windowsills

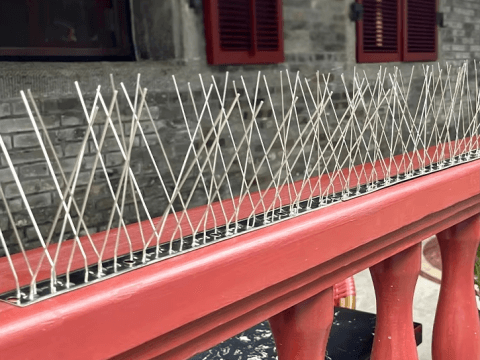

Railing top application

(7) Simple maintenance: The steel spike design reduces the accumulation of bird feces and debris, and the self-cleaning ability reduces the frequency of manual cleaning.

(8) Customization: Various specifications, Wanzhi Steel provides steel spikes of different lengths, diameters, and densities to meet the bird-proofing needs of different places.

(9) Optional colors: Supports galvanizing, plastic spraying, and other surface treatments to meet the aesthetic requirements of different environments.

Types of Anti bird spike

Classification by material

1. Stainless steel bird spikes: corrosion-resistant, high-strength, and most durable. Suitable for long-term outdoor use, commonly found in high-rise buildings, power facilities, etc. We offer 304 or 316 stainless steel materials.

2. Polycarbonate (plastic) bird spikes: lightweight, UV-resistant, and low-cost, integrated with architectural aesthetics (transparent or colored options). Mostly used for short-term protection or scenes with low material requirements (such as agricultural greenhouses and eaves).

Classification by structural design

1. Fixed bird spikes: The spikes are fixed to the base and arranged radially. After installation, the shape is fixed and the protection range is clear.

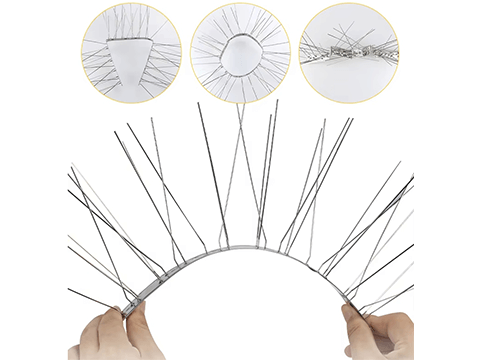

2. Bendable bird spikes: The base has a flexible material (such as a rubber strip) that can adapt to irregular surfaces such as arcs and circles (such as pipes and railings).

Prevent nesting under the eaves

Use on handrails

Used to prevent bird droppings on roofs

Application

1. Power industry: Installed on the crossarms, insulators and other parts of the transmission line, transformers in substations, switchgear areas, and the top of the distribution box to prevent birds from entering and causing safety hazards.

2. Construction: Installed on the edge of the roof, the platform of the air conditioner outside, the vents of the factory building, the crossbeams of the bridge, the entrances and exits of the tunnel, etc., to prevent birds from roosting or nesting.

3. Agriculture & animal husbandry: Installed above fruit trees and crops, chicken coops, pigeon house farms, to prevent birds from entering and spreading diseases or damaging facilities.

4. Transportation and infrastructure: Installed on railway signal equipment, highway lighting facilities and other parts, used around airport runways and navigation equipment areas to prevent bird strikes.

5. Ports and docks: Installed on equipment such as cranes and shelves to prevent birds from nesting or roosting.

6. Public facilities & municipal engineering: Installed on street lights, sculptures, observation decks, and other parts of parks and scenic spots, and also used in landfills, incineration plants, sewage treatment plants, and other areas to prevent birds from foraging or spreading diseases

7. Industry and manufacturing: Installed on chemical and oil storage tanks, pipelines, and reactor equipment to prevent birds from nesting or roosting and causing safety hazards.

Application on chemical pipelines

Use on top of fence

Use around the roof

8. New energy field: Installed on wind turbine blades, towers and other parts, used on the sides of photovoltaic panels to prevent birds from affecting power generation efficiency or damaging facilities

9. Ecological protection and scientific research: Install bird-proof spikes in nature reserves to prevent rare plants from being destroyed, and used in bird research stations to protect experimental equipment or observation points to prevent birds from interfering with research work.

Manufacturing process

1. Material selection: strictly select high-quality 304/316 stainless steel or UV-resistant polycarbonate.

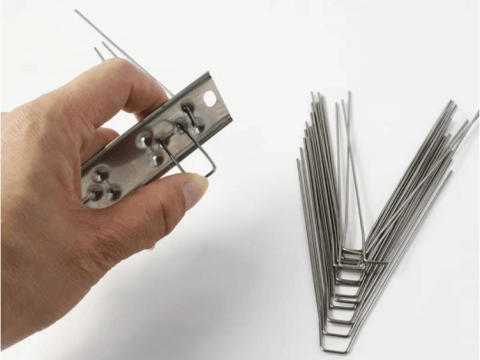

2. Spike molding + stamping: Spikes are formed by injection molding (plastic) or metal stamping (steel).

3. Base plate molding: Create a solid metal base to ensure a secure installation.

4. Assembly: Follow strict production standards to weld or bond the spikes to the base.

5. Surface treatment: optional polishing, galvanizing, or powder coating for enhanced corrosion resistance.

6. Quality inspection: After rigorous durability, strength, and stability testing, size review.

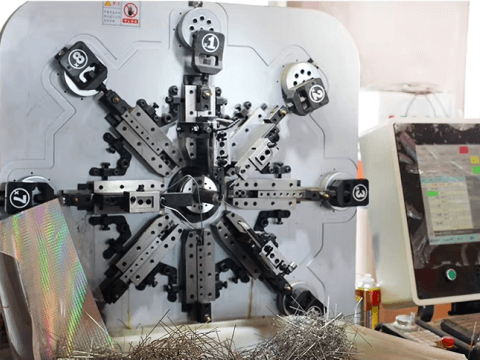

Automatic machinery production

Stainless steel spike production

Internal packaging

Quality Control Measures

1. Material testing: Verify stainless steel grade or polycarbonate quality.

2. Spike strength testing: Ensure spikes can withstand bird pressure without bending.

3. Weathering testing: Salt spray testing (for steel) and UV exposure testing (for plastic).

4. Adhesive/screw strength testing: Confirm secure installation.

Length can be customized

Steel strip can be bent

Easy assembly

Why choose Wanzhi Steel Anti bird spike?

As a leading manufacturer, we offer:

1. High-quality materials: 304/316 stainless steel and UV-resistant polycarbonate.

2. Professional equipment: mature automated production lines to ensure high consistency in product precision.

3. Customizable designs: different lengths, colors and mounting options. OEM/ODM services are available for special needs.

4. Competitive prices: 1,000 square meter factory, wholesale supply, bulk orders can enjoy volume discounts.

5. Worldwide delivery: reliable logistics cs ensure timely delivery.

Wanzhi Steel Workshop

10015 pieces shipped to Yemen

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Anti climb spikes, Common nails, Coil nails, Galvanized bolts, Roofing nails, Fence staples, Galvanized spikes, and Duplex nails for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message