Galvanized Concrete Mesh

Wire Diameter: 4 mm – 14 mm

Spacing: 50 mm -400 mm

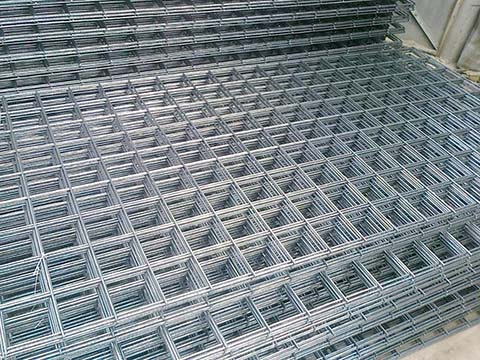

Packaging: In Panels

Galvanized Concrete Mesh

Galvanized concrete mesh is a kind of welded wire fabric, which is an irreplaceable part of modern construction. It is made of high tensile steel wire, which is welded into square or rectangular mesh for concrete reinforcement uses. It is widely used in industrial and civil houses, including beam, floor, roofing, wall panels, concrete pavement, bridge pavement, tunnel lining, etc. Wanzhi Steel is a leading manufacturer of steel mesh products. We offer various galvanized reinforcing meshes in different diameters, opening sizes, and mesh sizes. Welcome to contact us for more details!

Galvanised Reinforcing Mesh

Galvanized Concrete Mesh

Specifications of Galvanised Concrete Mesh

Material: Low carbon steel wire, galvanized wire

Surface Treatment: Galvanized

Opening Shape: Rectangular or Square

Wire Diameter: 4 – 14 mm

Spacing: 50-400 mm

Mesh Width: 0.65 m – 3.4 m

Mesh Length: 0.5 m – 12 m

Below are some of the specifications we often export for your reference only. In addition, we support custom sizes. If you have special requirements, please let us know the first time. We will have professional designers to provide you with the most satisfactory style.

| Opening | Wire Diameter | ||

| Inch | mm | BWG | mm |

| 1″ × 1″ | 25 mm x 25 mm | 14# – 11# | 2.0 mm – 3 mm |

| 2″ × 1″ | 50 mm x 25 mm | 14# – 8# | 2.0 mm – 4 mm |

| 2″ × 2″ | 50 mm x 50 mm | 14# – 8# | 2.0 mm – 4 mm |

| 3″ × 2″ | 75 mm x 50 mm | 14# – 6# | 2.0 mm – 5 mm |

| 3″ × 3″ | 75 mm x 75 mm | 14# – 6# | 2.0 mm – 5 mm |

| 4″ × 2″ | 100 mm x 50 mm | 14# – 4# | 2.0 mm – 6 mm |

| 4″ × 4″ | 100 mm x 100 mm | 14# – 4# | 2.0 mm – 6 mm |

| 5″ × 5″ | 125 mm x 125 mm | 14# – 4# | 2.0 mm – 6 mm |

| 6″ × 6″ | 150 mm x 150 mm | 14# – 4# | 2.0 mm – 6 mm |

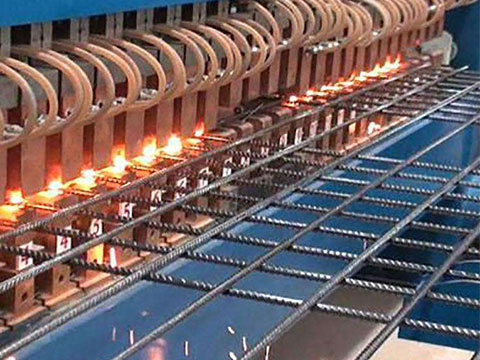

Galvanized Concrete Mesh Production Line

Quality Inspection

Applications of Concrete Reinforcing Mesh

Galvanized steel reinforced mesh is an ideal option for both industrial and civil construction, such as beams, columns, floors, roofs, walls, concrete pavements, bridge decks, etc.

1. Reinforcement of road surfaces or parking areas, such as concrete sidewalks, floor blocks, residential floor slabs, and foundations.

2. Reinforcement of concrete structures in building, for example, reinforcement of hollow panels, wall body, or supporting wall; ground for tunnels, bridges, highway, etc. It can increase the strength of concrete structures.

3. Other uses, such as manufacturing fences or frames, gabions, etc.

Wall Panel

Floor Slabs

Futures of Galvanised Reinforcing Mesh

Galvanised steel reinforcing mesh offers many advantages, for example,

1. High Strength & Good Stability

Galvanized reinforcing mesh has high strength, high plasticity, and impact absorption capacity. The tensile strength of raw materials is up from 1200 MPa to 1580 MPa. So the reinforced mesh can resist external forces caused by natural disasters, such as strong winds, and earthquakes. When the building deforms, the mesh makes the building not collapse or crack soon. That’s why it is widely used in the construction industry.

2. Excellent Corrosion Resistance

Through hot-dip galvanizing or electro-galvanizing, there is a zinc layer that protects the steel surface from corrosion and rust. The excellent corrosion resistance will prolong its service life.

3. Improve Project Quality

Our concrete reinforcing mesh is produced by a fully automatic intelligent production line. From the size and specification to the quality of the mesh is strictly controlled. The mesh produced by Wanzhi Steel has the characteristics of large steel degree, high strength of welded joints, good elasticity, uniform, and accurate mesh spacing, and good anti-cracking performance. The quality of the mesh is good, which also means the quality of the project will be greatly improved.

4. Easy to Install

Galvanised reinforcing mesh is light in weight, and it is easy to put in the desired position, which makes it easy and quick to install. So using welded reinforced mesh will shorten the construction period (up to 50% to 70%) to save your cost largely.

5. Cost-Effective Solution

Reinforced mesh consumes 30% fewer steel bars during the production process. Besides, due to its great anti-corrosion properties, it can be used in various applications including outdoor environments for a long time. The long service life also makes it cost-effective. So the low-cost mesh is very suitable for large concrete engineering.

Wire Mesh for Concrete

Galvanized Reinforcing Mesh

What Is Galvanized Rebar Mesh?

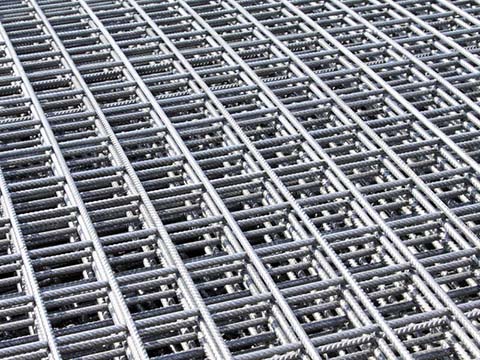

Reinforcement steel mesh is made of low carbon steel rebars. After rust removal and oiling treatment, it is processed into mesh products by welding or binding. These longitudinal and transverse steel rebars are arranged at a certain distance to form square or rectangular openings. Then the whole mesh is dipped into a zinc molten bath to apply a zinc coating on the surface. An automatic steel mesh production line includes automatic wire feeder, automatic cutting machine, welding equipment, etc. Please note that a quality wire mesh has a smooth surface without bending except for special requests. Secondly, the wire diameter difference should be within the range of 0.05 mm, and the opening tolerance is within 5 mm.

1. Production Processes

carbon steel wire welded into a network → heating → cooling to the required temperature of hot-dipped/ electro galvanizing → cooling → storage

Our factory is located in Hebei Province, China. If you want to know more details about the production of galvanized concrete reinforcing mesh, you can contact us for a factory tour.

2. What Is the Strength of Galvanized Concrete Mesh?

The galvanized concrete mesh produced by Wanzhi Steel has a tensile strength of 510 MPa and minimum impact strength of 485 MPa. This means that it can withstand external impacts very well. Besides, the concrete mesh we produce is galvanized to resist corrosion and rust. Therefore it is very durable and has a long service life.

3. Why Use Galvanized Wire Mesh for Concrete?

Welded galvanized wire mesh is able to control concrete cracking. Also, it can evenly distribute structural weight throughout. More than that, it is also easy and quick to install, which will reduce labor hours and installation costs. That’s why galvanized concrete mesh is very popular in construction.

Reinforced Mesh

Galvanized Reinforced Mesh

Types of Concrete Reinforcing Mesh

When you start looking for concrete reinforcing mesh, you will find that there are many varieties and shapes of concrete mesh to choose from. Wanzhi Steel offers to mesh in different opening shapes and sizes. No matter what purpose you are using it for, these meshes are sufficient to meet your needs. Below are the common types of mesh for your reference.

1. Square Wire Mesh

Square shape is the most common shape of reinforcing steel mesh. It is available in many sizes and is the best choice for construction purposes. In addition, this rebar mesh is customizable. No matter which size you need, you can find it at Wanzhi Steel.

2. Rectangular Mesh

This type of reinforcing mesh has different spacing in each direction, forming rectangular holes. It is the ideal mesh for floor and wall panels. In addition, rectangular mesh is strong and crack resistant, and easy to construct. If you are shopping for mesh for your construction project, it is a good choice.

3. Trench Mesh

Trench mesh is usually a long and narrow sheet. It is usually made of carbon steel and has a very high tensile strength. People often use trench mesh for reinforcing concrete footings and beams in residential and industrial buildings. Wanzhi Steel produces trench mesh in four sizes, 8, 11, 12, and 16, by AS/NZS 4671: 2001 for steel reinforcement materials. You can choose according to your actual needs.

4. Ribbed Steel Mesh

Ribbed reinforcement mesh uses steel bars that are ribbed. The shape of the ribs improves the bond with the concrete and minimizes possible concrete cracks due to concrete shrinkage. It is available in different opening shapes, such as square and rectangular, and is popular in the construction industry.

Square Wire Mesh

Trench Mesh

Ribbed Steel Mesh

Concrete Steel Mesh Prices

The price of steel wire mesh is influenced by many factors, such as the wire gauge, material, zinc coating thickness, etc. Galvanized reinforcing mesh is welded mesh sheet, which is made up of high tensile strength wires. You can choose according to the use purposes and environment. But generally speaking, welded wire meshes are economical. Aside from construction projects, it can be also used in enclosures and safety guards, etc. It means it is also promising to invest in. Wanzhi Steel is a top steel wire mesh manufacturer in China, which will offer you a cheap price and discounts for bulk orders. Welcome to contact us for the latest price.

What to Consider Before Purchase?

1. Pay attention to the specifications, such as wire diameter, spacing, and weight. It mainly depends on the different uses.

2. Technical properties, such as steel stiffness and strength

3. Concrete production process and compatibility

4. Quality of steel wire mesh and the suppliers.

For example, the reinforced mesh for the floor often uses wire with a diameter of 3 mm-6 mm. While for floor heating mesh, 1 mm to 3 mm wires are a better chioce. However, for bridge or high-speed railway projects, the wire diameter is 8 mm-10 mm or even more thicker. You can choose according to the use purposes. As an investor, you need to choose according to the local market. Wanzhi Steel stocks a wide selection of galvanized reinforcing meshes. For more information, please contact us.

Galvanized Concrete Meshes

GI Concrete Mesh for Sale

How to Judge the Quality of Galvanized Concrete Mesh?

When buying galvanized concrete reinforcing mesh, how can you tell whether it is of good quality or not? If you have any questions about this, Wanzhi Steel will tell you the answer next.

1. First of all, you have to determine whether the welded joints of galvanized concrete mesh have a tensile strength that meets the specification standards. If the weld is not strong, then the welded joints will be prone to cracking when the concrete is poured.

2. Secondly, you can observe whether the surface is smooth or not. The surface of high-quality galvanized concrete mesh must be shiny. If it has a rough and dull surface, then it is definitely of inferior quality.

3. Finally, you can judge the quality of welded wire fabric based on its price. Its market price will not vary too much. If a manufacturer gives a minimum price, then it may cut corners in its production.

Galvanised Steel Reinforcing Mesh

High Quality Galvanized Concrete Mesh

Buy Galvanized Concrete Mesh from Wanzhi Steel

Wanzhi Steel has been exporting galvanized concrete mesh for more than ten years. Our products are exported all over the world, such as Germany, Philippines, Egypt, Ireland, Canada, and so on. Our customers have given us high praise and have been keeping a cooperative relationship. If you are planning to buy galvanized concrete mesh, please let Wanzhi Steel be your first choice.

1. Refined Material Selection

Our factory uses high quality coil steel, and all parameters are in line with national standards. In addition, each batch of our products undergoes multiple quality checks to ensure that the quality is up to par. Therefore, you can not worry about the quality of our products.

2. Firm Welding

Wanzhi Steel factory is equipped with CNC automatic rebar mesh seam welder to ensure the production of concrete mesh with a flat surface, uniform mesh holes, and firm welding. Not only that, but the production efficiency of galvanized concrete mesh is also high, which can quickly meet your orders.

3. Standard Specification

Our galvanized concrete mesh is made in strict accordance with standard wire diameter and mesh size. In addition, we can also produce according to the size requested by our customers. If you have custom requirements, please let us know first. We will design the galvanized concrete mesh for you according to your requirements.

Concrete Reinforcing Mesh in Wanzhi

Fence delivered with support posts

Conclusion

The galvanized reinforcing mesh is welded through automated machinery. The zinc coating provides full protection so that it is very durable and long-lasting. Besides, it has features of large rigidity, good elasticity, and uniform spacing, which makes it suitable for many applications. At Wanzhi Steel, the wire mesh comes in square and rectangular openings and is available in a wide range of specifications. Also, we will offer custom solutions to better meet your needs. If you are looking to make your projects more durable and cost-effective, please contact us for more information.