Stainless Steel Wire

Steel Grade: 304, 304L, 316, 316L, 302, 304H, 201, 430, etc series

Wire Diameter: 0.5 – 20.0 mm

Packing: Spool, Carrier, Coil, or Can be specified

Weight: 1kg – 1,000 kg in coil or can be customized

Delivery days: 15-21 days

Stainless Steel Wire

Stainless steel wire is a common high-performance steel wire, known for its good corrosion resistance & high cost performance. It is used for hanging pipes, medical equipment, hardware springs, pointers, bundling items, etc. It can also be twisted into wire ropes, such as cables and strands. There are different grades, and the cross-section is round or oval. Wanzhi Steel, as a high-quality manufacturer of SS wire, stocks many SS steel wires with regular wire diameters, and has 200, 300, 400 series for you to choose from. You are welcome to contact us to learn more.

stainless steel wire

wire of stainless steel

Specifications of SS Steel Wire

| Item | Stainless steel wire |

| Place of origin | Hebei, China |

| Standard | AISI, EN, GB, ASTM, JIS |

| Type | Hot Rolled/Cold drawn Wire/Annealed/Spring |

| Surface | Bright, black, phosphates, nylon coated stainless steel wire |

| Sample service | Available |

| Price Term | Ex-work, FOB, CIF, CFR, etc |

| Payment method | T/T 30% Deposit |

| Certificate | MTC, ISO9001, BV, TUV |

| Transportaion | By sea |

| MOQ | 5 Tons |

| Use | Springs, nails, Jewelry making, screws, bolts, nuts, binding wire, stiching wire, baling wire, staples |

Common grades of SS steel wire

- 304 (A2): non-magnetic, ASTM A276, food-grade stainless steel.

- 304L: non-magnetic, ASTM A580, low-carbon version of 304, welding, chemical corrosion protection.

- 316 (A4): non-magnetic, ASTM A313, containing Mo element, upgraded version of 304, high acid and alkali resistance, marine grade.

- 316L: non-magnetic, ASTM A580, low-carbon version of 316, pharmaceutical, nuclear industry, high-purity chemical containers.

- 410: strong magnetism, ASTM A580, knives, springs, wear-resistant machinery.

- 420: strong magnetism, ASTM A313, high carbon, surgical instruments, high hardness.

- 430: magnetic, chloride corrosion resistance, but poor weldability.

- 2205: high-performance duplex stainless steel with high strength and good corrosion resistance.

Cold drawn 304 stainless steel wire

SS spring wire

Stainless steel wire can be used as binding wire, locking wire, or safety wire, made into cables, or used as stainless steel welding wire and springs. Special coatings can be added to its surface, such as vinyl-coated black stainless wire, to enhance performance.

Chemical composition

- 304 stainless steel: Cr18.0%-20.0%, Ni8.0%-10.5%, C≤0.08%, Mn≤2.0%, Si≤1.0%, P, S≤0.035%.

- 316 stainless steel: Cr16.0%-18.5%, Ni10.0%-14.0%, Mo2.0%-3.0%, C≤0.08%, Mn, Si, P, S≤0.035%.

- 410 stainless steel: Cr11.5%-13.5%, C0.08%-0.15%, a small amount of Mn, Si, P, S.

- 430 stainless steel: Cr about 16.2%, C≤0.12%, Mn, Si, P, S content is low.

Features of stainless steel wire

- Excellent corrosion resistance: the formation of dense chromium oxide protective film on the surface can prevent oxygen, moisture, and other corrosive media from contacting the base metal, thus providing high corrosion resistance. 304 stainless steel wire can last for decades without corrosion.

- High Strength: High tensile strength enables it to withstand large external forces without breaking. It can be used to make springs and wire ropes.

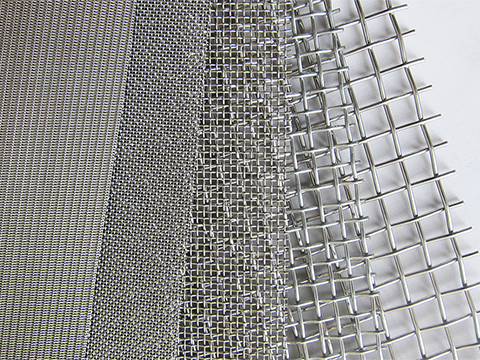

Various stainless steel wires in stock

Stainless Steel Annealed Wire Manufacture

- High toughness: it performs well when subjected to impact or bending, and is very suitable for parts that require frequent deformation.

- Magnetic differences: austenitic stainless steel wire (such as 304, 316, etc.) is usually non-magnetic or weakly magnetic, ferritic stainless steel wire and martensitic stainless steel wire is magnetic.

- High temperature resistance: 310S stainless steel wire has excellent oxidation resistance and creep resistance at high temperatures, can be used for a long time in a high temperature environment of 1100 ℃, commonly used in the manufacture of furnace wire, thermocouple protection tube.

- Low temperature resistance: 304L stainless steel wire in -196 ℃ liquid nitrogen temperature can still maintain good toughness, can be used in cold storage, ice cellar, cold areas.

- Hygienic: It does not react chemically with food and does not release harmful substances, so it is widely used in food processing, catering and medical industries.

- High surface finish: it has good decorative properties after polishing treatment, and can also be presented in gold, black, color and other colors through surface treatment.

mig welding stainless steel

stainless steel locking wire

Commonly used diameters

Fine stainless steel wire

0.15mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 28 gauge, 0.4mm, 26 gauge, 0.5mm (24 gauge). Also called SS soft wire. Commonly used 304/316/410/430 grades.

Medium Diameter

0.6mm, 0.7 mm(22 gauge), 0.8 mm, 20 gauge, 1mm(19 gauge), 1.2 mm(18 gauge), 17 gauge, 1.5 mm, 1.6 mm(16 gauge), 2mm(14 gauge), more versatile. Commonly used 304/316/430/410 grades.

Heavy Duty Stainless Steel Wire

2.5 mm(12 gauge), 3mm, 3.2 mm, 9 gauge, 4mm(8 gauge), 5mm, 6mm, 8mm.Commonly used 316/2205/430/2507/410, thicker, wear-resistant, and durable.

stainless steel wire tie

Wholesale Straight Cut Wire

Uses

Corresponding applications for different diameters(Unit: mm)

- 0.01-0.05: Minimally invasive surgical sutures, precision electronic components (e.g. coils, sensor wires).

- 0.05-0.1: Dental orthodontic wires, optical instrument springs, high-precision sieves.

- 0.1-0.3: Jewelry braided wire, fishing line, precision springs (watches, instruments), anti-counterfeit label embedded wire.

- 0.3-0.5: Hardware hooks, wire rope core wire, oil filter mesh, industrial woven wire mesh (such as food conveyor belt).

- 0.5-1.0: automobile suspension, home appliance springs, elevator wire rope, horticultural tying wire, animal cage netting.

- 1.0-3.0: ship cables, building structural ties, high-pressure sealing gasket reinforcing wire.

- 3.0-6.0: oil drilling wire rope, explosion-proof net (chemical plants), large animal fences, heavy machinery drive chain.

- >6.0: submarine cable armor layer, harbor collision guardrail, large steel structure reinforcement tendons.

Mask Wire

wire cable railing

steel mesh screens

Areas of application

- Spring: Compression springs, extension springs, torsion springs, engine valve springs, clutch springs, etc., need to withstand high temperature, high pressure & frequent alternating loads.

- Strainers & screens: In the chemical, petroleum & food processing industries, filter screens, metal screens, steel fences, hardware cloth, mesh pipes, as well as mesh rolls thanks to their safety and stability.

- Indoor & outdoor decoration: wall and ceiling edging and decoration, stainless steel wire guardrails and handrails are widely used in staircases, balconies and courtyards.

- Building Structure Reinforcement: In large-scale projects such as bridges and high-rise buildings in coastal and humid areas, stainless steel wire pre-stressing tendons can effectively resist earthquakes, wind, and ensure safety.

- Kitchenware: steel wire balls, cleaning brushes, baking nets, woven steamer baskets are used, and their abrasion and corrosion resistance ensures long-term use.

steel braided cable

Fishhook

SS cable tie

- Household: stainless steel wire coat racks, safety locking wires, tying wires, sewing needles, woven cloth, baskets, metal mesh pipes, shelves, SS steel balls for bearings, etc.

- Medical devices: surgical sutures, suture needles, dental wires, vascular stents, etc. It has good biocompatibility, strength, and flexibility.

- Aircraft parts: under the high requirements of the aerospace field, engine parts, flight control system connectors are often made of stainless steel, which can withstand high temperature, high pressure and high speed rotation.

Stainless Steel Wire Rope

Stainless steel wire rope consists of multiple strands of steel wire stranded together, with the strands wrapped around a central core, and a number of different sizes of steel wire combined in a helical shape to provide the user with maximum corrosion protection and superior abrasion resistance. As a result, wire rope provides a safe option for many critically important construction projects. Wanzhi Steel produces single and multi-strand stainless steel wire ropes in 1*7, 1*19, 7*19, etc., and the structure and wire diameter can be specified.

ss wire rope

stainless wire rope

steel wire rope

What is the difference between cable and wire rope?

The general rule is that if the rope diameter is greater than 3/8 inch (9.525 mm), it is classified as a wire rope, but if the diameter is less than 3/8 inch, it is classified as a cable or rope.

Stainless steel wire production process

The production process of stainless steel wire mainly includes raw material preparation, smelting, casting, rolling, drawing, heat treatment, surface treatment, at last the final inspection.

- Selection: Use high quality stainless steel coils, commonly used 304, 316 models.

- Surface treatment: surface oxide removal, commonly used pickling method.

- Heating and rolling: Through multiple rolling processes, the cross-section of the raw material is gradually reduced, and the length is increased to form stainless steel bars or wires.

- Drawing: pickling, phosphating, annealing, normalizing and other heat treatment. The coils are then drawn through a wire drawing die to the required diameter of fine wire.

- Heat treatment: Common heat treatment processes include quenching, tempering, etc. Quenching improves the strength and hardness of the wire, while tempering removes the quenching stress.

- Surface treatment: Color or addition of vinyl coating, nylon coating can be achieved.

- Testing and packaging: testing for dimensional accuracy, mechanical properties, surface quality, corrosion resistance, etc. Qualified candidates are packed in rolls or disks, using moisture-proof and rust-proof packaging materials.

316l stainless steel wire rod

Wire Production Line

316l stainless cold drawn steel wire

Stainless steel wire classification method

Classification by process

- Stainless steel soft wire: code S, bright surface, soft, non-magnetic, fatigue-resistant, large elongation.

- Ss steel light drawn wire: code LD, bright surface, relatively soft, fatigue-resistant, with certain elongation.

- Ss steel cold drawn wire: code WCD, smooth surface, good toughness, wear resistance.

In addition, ss steel filaments generally refer to steel wires with a diameter of no more than 0.05 mm, which we mainly use for weaving nets and making ropes and springs.

Classification by material

- Austenitic stainless steel: mainly 304, 304L, 316, 316L, and so on. Among them, 304 and 316 are good corrosion resistance, cost-effective varieties. 316SS steel contains molybdenum, better resistance to chloride corrosion, and can be used in marine environments.

- Ferritic stainless steel: For example, type 430 is a common chromium steel with good corrosion and heat resistance, but it cannot be strengthened by heat treatment.

MIG stainless steel

stainless steel spring wire

stainless steel mesh

- Martensitic stainless steel: such as type 410, type 416, we can strengthen its heat treatment, high hardness, good machinability, commonly used in general heat-resistant, corrosion-resistant fasteners.

Classification by purpose

- Spring steel wire (common steel grades 302, 304, 316, and 631)

- Welding wire (ER308, ER309 and ER321)

- Cold top steel wire (430, 410, 304M, 304HC, 302HQ, 316, and 305)

- Mesh steel wire (430, 304, 316, and 310)

- Precision shaft steel wire (420J2, 4Cr13 and 303)

- Rope steel wire (304, 316)

- General-purpose steel wire, such as nail making, cleaning ball, binding wire, and wire drawing (405, 410, 430, 430L, 304, 04HC, and 316, etc.).

ss steel welding wire

Single Loop Baling Wire

Annealed Binding Wire

SS Wire Export Case

304 stainless steel wire shipped to Kazakhstan

Selection suggestions for SS wire

- Application scenarios: precision equipment requires very fine wire, structural engineering requires coarse wire, corrosive stronger environment using 316 grade material.

- Strength requirements: when high strength and high hardness, you can choose coarse cold drawn stainless steel wire, while fine wire is flexible and easier to bend.

- Processing technology: braiding, welding, coating and other processes have different requirements for wire diameter.

- Cost budget: fine wire cost is high, coarse wire is better cost performance, regular manufacturers quality is guaranteed.

3mm stainless steel wire

316l SS wire package

Stainless steel wire suppliers – Wanzhi Steel

1. Whether you know stainless steel or not, it doesn’t matter. Because Wanzhi Steel QC department will recommend suitable specifications and models according to your application.

2. You only need to send the total quantity you need, our MOQ: 5 tons

3. Then, we believe our expertise will give you a satisfactory solution and product.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of GI Wire, SS wire, annealed wire, galfan wire, PVC Coated GI Wire, Oval Wire, Baling Wire, and zinc-aluminum alloy wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message