Wanzhi Steel has welcomed a customer from Venezuela, a South American coastal country, and reached a cooperation of 457 tons of reinforcing mesh. The following is the progress of cooperation.

Client Background

The customer in this cooperation is a large construction company from Venezuela, specializing in infrastructure construction, such as roads, bridges, houses, and so on. The company has a good reputation and rich project experience in Venezuela, with a high demand for construction materials and strict requirements for product quality.

Customer orders:

Grade: HRB335, HRB400

Size: Diameter 5.9mm, L×W 448×220cm

Process: Hot rolled ribbed, Plain round steel bars

Surface treatment: Bare (Black), no requirement

Quantity: 457 tons

Port: Venezuela Bolivar Port (VECBL)

Factory wholesale price

Hot Rolled Ribbed Steel Mesh plate

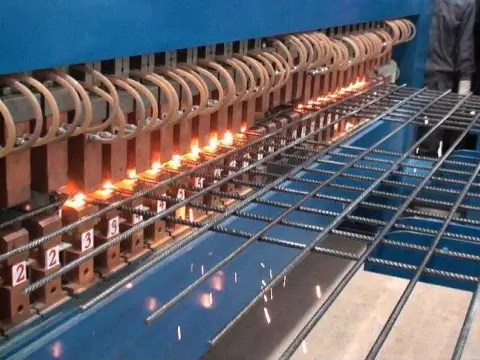

Production process of reinforcing steel mesh project

Conforming hot rolled ribbed steel bars → straightening, cutting, bending → arranging, welding, mechanical connection → hot-dip galvanizing treatment/epoxy coating (this step is omitted in this project because the customer does not need the surface treatment) → quality inspection (mechanical properties, surface quality, welding quality, dimensions) → bundling and packaging → rational storage

Ribbed Reinforcement Bars

Welding according to dimensions

Customized Reinforcing Steel Mesh

Usage of Reinforced Steel Mesh

Recommended applications for different sizes

1. According to the diameter of the rebar

4mm-6mm diameter: light structure, building decoration

8mm-12mm diameter: floor, roof, wall, bridge structure construction

14mm+: key parts of large bridges and large water conservancy projects.

2. According the to mesh size

50mm×50mm, 100mm×100mm mesh: floor slabs, roof panels, pools/basement, etc.

150mm×150mm, 200mm×200mm mesh: to ensure structural strength, taking into account the convenience and economy of construction. Concrete pavement, bridge deck.

250mm×250mm+ mesh: temporary works, secondary structures, etc.

Fields of application

Column Structural Components

Concrete Pouring for Road Surfaces

For sidewalk stone piers

-Waterproofing: used in combination with waterproofing materials in waterproofing of basements and tunnels.

-Concrete structure: as a stress skeleton, used in floor slabs, walls, columns, and other concrete components.

-Road construction: reinforcement of pavement base, used in highway and railroad construction.

-Tunnel and underground: crack-resistant reinforcement of underground garages, basements, and other structures, as well as tunnel lining construction.

-Slope protection: used in combination with vegetation to prevent landslides through the process of hanging mesh slurry spraying.

Quality inspection of reinforcing mesh at the factory

Wanzhi Steel will check the mesh surface for cracks, bubbles, slag, and other defects. As well as all dimensional parameters, and quality of welded joints.

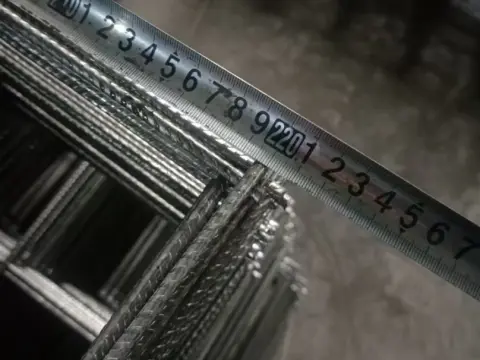

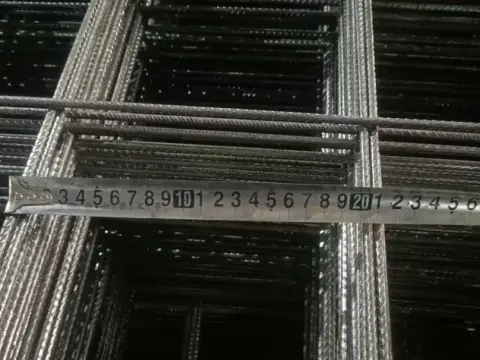

Size inspection

5.9mm diameter

Width 220cm

Hole OD 21mm

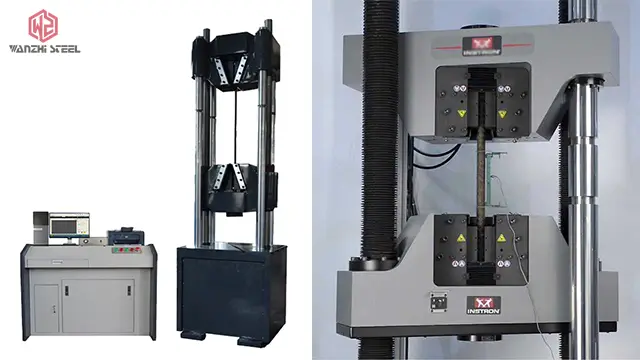

Quality inspection

The mesh will be subjected to tensile tests, bending tests, etc. to make sure that its mechanical properties are in accordance with HRB335 and HRB400 standards.

Tensile test, bending test

Packing of the welded rebar mesh sheet

The customer of this project does not have strict requirements for packaging, and we use steel tape bundling. Desiccant is placed inside the package to prevent moisture and rust. And the specifications and factory information are pasted.

Transportation

Wanzhi Steel has a fixed partner shipping company, the goods are loaded into containers for shipping and finally arrive at Bolivar Port (VECBL) safely and on time.

shipment

load mesh panels onto a truck

If you are also interested in reinforcing steel mesh, welcome to contact Wanzhi Steel.

WhatsApp: 8613938459717

Email: info03@wanzhisteel.com

Leave Us A Message