Color Coated Coil

Thickness: 0.02-1.2mm

Width: ≤1500mm

Coating: PE, SMP, HDP, PVDF(top11-35μm, bottom5-14μm)

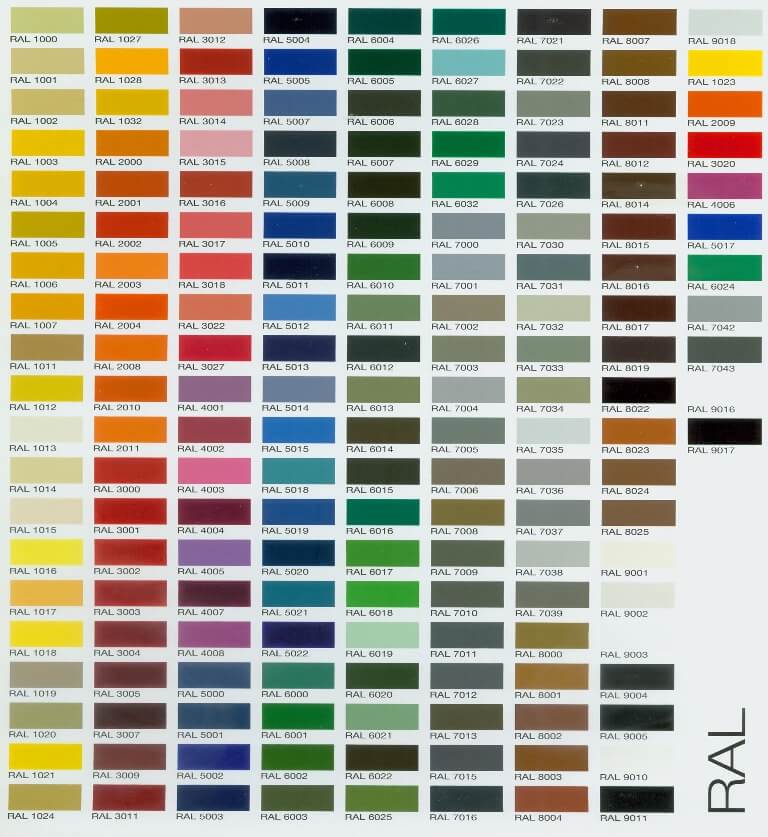

Color: RAL color

Color coated coil

Color coated coil, also known as pre-coated steel coil, is a metal coil with both aesthetics and practicality. It is made of galvanized steel(GI), galvalume steel(GL), cold-rolled steel(CR), or aluminum and is used in construction, home appliances, automobiles, and other industries. Wanzhi Steel stocks full-size color coated steel coils. Besides, we accept a wide range of colors and finishes, including Matt/Glossy/Frosted/Wrinkled/Embossed/Textured. We also accept third-party testing, if you want to know more, please contact us.

Embossed Wrinkled PPGI PPGL Color Coated Steel Coils

RAL5015 PPGI Coil China manufacture

Color-coated coil Specification

| Item | Color coated coil(Color Galvanized Steel Coil, color Galvalume Steel Coil) |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Keyword | Color Zinc Coated Coil, color coated aluminum zinc coils |

| Material | SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z/Q195-q345 |

| Length | As customer’s requirement |

| Oiled or Non-oiled | Slightly Oiled |

| Technique | Hot Rolled Based |

| Shape | Plate/ Coil/ Strip |

| Sample | Free Available |

| Transport | By sea |

| Delivery | 18-28 days |

| MOQ | 3 Tons |

| Packages | Standard Seaworth Packing |

| Payment | T/T 30% prepayment |

| Place of origin | Shandong, China |

PPGI Pre-Painted Galvanized Four coating types:

1. Polyester (PE)

Good adhesion, rich colors, a wide range of formability and outdoor durability, medium chemical resistance, and low cost.

2. Silicone-modified polyester (SMP)

Good coating hardness, wear resistance, heat resistance, good outdoor durability and anti-powdering, average light retention and flexibility, and medium cost.

3. High-durability polyester (HDP)

Excellent color retention and UV resistance, excellent outdoor durability and anti-powdering, good coating adhesion, rich colors, and excellent cost performance.

4. Polyvinylidene fluoride (PVDF)

Excellent color retention and UV resistance, excellent outdoor durability and anti-powdering, good formability, good stain resistance, limited colors, and high cost.

The most popular

The most popular options include sky blue, grey, silver, traffic red, moss green, olive green, and signal white.

Ral-colour-chart

Production Video

Color coated coil weight calculation formula

Color plate thickness (mm) × width (m) × total number of meters (m) × 7.85 = Weight (kg)

Note: 7.85 is the density of iron, and each cubic meter of iron weighs 7.85kg.

Product Advantages

glossy ppgi steel coil galvanized DX51D

1. Anti-corrosion: 13 years in heavy industrial areas, 50 years in the ocean, 104 years in suburbs, and 30 years in cities.

2. Cheap: Hot-dip galvanizing costs less than other coatings.

3. Reliable: The zinc layer is metallurgically bonded to the steel and becomes part of the steel surface, making the coating more durable.

4. Strong toughness: The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

5. Comprehensive protection: Every part of the plated part can be galvanized, and it can be fully protected even in recesses, sharp corners, and hidden places.

6. Time/labor-saving: The galvanizing process is faster than other coating methods and is easy to install and carry.

7. Beautiful: A variety of colors and finishes are available to meet design requirements.

Application

- Buildings: Roofs, wall coverings, and structural components.

- Appliances: Refrigerator, washing machine, and oven panels.

- Automotive: Body panels and other components.

- Furniture: Office partitions, cabinets, and shelving.

Blue corrugated roof panel

Billboard writing board

Grass pattern color coated sheet

Different surface treatments

- Normal Surface: Regular surface with different colors, according to RAL codes.

- Matt Surface: Surface is matt which is not smooth.

- Designed Patterns: Such as flower printing, brick grain, wooden grain, warning tape, etc.

- Wrinkled Surface: The surface is wrinkled or embossed with different patterns.

We also provide matte, orange peel, frosted, textured, glossy and other surface treatment services.

Orange peel and embossed surfaces

Matt and frosted surface

Manufacturing process

1. Cleaning: Clean the base metal coil to remove any oil, dirt, or oxides.

2. Pretreatment: Chemical pretreatment is performed to enhance the adhesion of the coating.

3. Priming: Primer is applied to provide additional corrosion resistance.

4. Topcoat: The final color coat is applied, usually followed by a protective clear coat.

5. Curing: The coated coil is baked in an oven to cure the paint and ensure durability.

6. Inspection: measure coating thickness, check surface flatness, and test whether various indicators meet process standards.

High quality galvanized steel substrate

Coating structure type

| Coating structure type | Upper surface coating | Lower surface coating | Number of bakes | Features |

| 2/1 | Two coats | One coat | Twice | Single-layer back paint, poor corrosion resistance and scratch resistance, but good adhesion, suitable for sandwich panels. |

| 2/1M | Two coats | Two coats | Twice | Double-layer back paint, good corrosion resistance, scratch resistance, and processing and forming properties, good adhesion, suitable for single-layer corrugated panels and sandwich panels. |

| 2/2 | Two coats | Two coats | Twice | Double-layer back paint, good corrosion resistance, scratch resistance, and processing and forming properties, but poor adhesion, suitable for single-layer corrugated panels. |

Textured PPGI wood grain steel coil

Wood grain PPGI steel coils China Manufacturer

Color coated coil Price

In general, the price of color-coated coils is determined by: raw material cost, coating type, plate thickness, and color factors.

For example, Ordinary polyester coated color-coated coils, High-end PVDF coated color-coated coils, and Aluminum-based color-coated coils has different prices.

The average price is 450-700 USD/ton, for complex craftsmanship price is 700-900 USD/ton, and the high end is 900+ USD/ton.

If you want to know the latest price,

please contact us now. We will reply in 8 hours.

Note:

Cold-rolled steel substrate: lower price. Galvanized steel substrate: medium price, better corrosion resistance. Aluminum substrate: higher price, lightweight, and corrosion-resistant.

White color coated ZAM coil

RAL 9016 white ppgi coil

Color coated coil VS Galvanized Coil VS Stainless Steel Coil

| PRODUCT | Advantages | Disadvantages | Price comparison |

| Color Coated Coil | Various colors, corrosion resistance, strong weather resistance, can be used directly without secondary coating | Special coatings are more expensive. | Medium (depending on coating and substrate) |

| Galvanized Coil | Good corrosion resistance, low price, suitable for general anti-rust needs | Single appearance (silver-gray), additional painting is required to meet aesthetic requirements. | Lower (about 20-30% cheaper than color coated coil) |

| Stainless Steel Coil | Extremely strong corrosion resistance, high-end appearance, long service life | Expensive, heavy, difficult to process | Higher (2-3 times the price of color coated coil) |

Metal Coil Selection Advice

- Limited budget and low aesthetic requirements: Choose galvanized coils or ordinary cold-rolled coils, and then paint as needed.

- Need high weather resistance and aesthetics: Choose color-coated coils, especially PVDF coatings.

- Lightweight and high corrosion resistance: Choose aluminum coils or stainless steel coils, but consider the cost.

Color coated coil Package

color coated coil inner package

Z275 galvanized steel coils sheet DX51D Q235

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer.

Q: Can we visit your factory?

A: Very welcome, we will pick you up once we get your schedule.

Q: Do you have quality control?

A: Yes, we have gained SGS authentication, and CE ISO.

Q: Can you arrange the shipment?

A: Of course, we have a fixed freight forwarder, can get the best price from most shipping companies, and provide professional service.

Q: How long is your delivery time?

A: If it is in stock, it is usually 7-14 days. If it is not in stock, it is 25-45 days, depending on the quantity.

Q: What is your payment term?

A: TT ,LC ,Western Union

Q: Can we get the some samples? Is it charged?

A: Yes, you can get available samples from our stock. Real samples are free, but customers need to pay for the shipping.

SGCC-Dx52D-PPGL-Color-Coated-Coil

Military camouflage print SGCC ppgi coil

Mongolia color-coated coils project

Color coated coil Manufacture- Wanzhi Steel

Our main products are stainless steel, carbon steel, galvanized, aluminum, color drawing, corrugated board, various profiles (section steel, Angle steel, channel steel, etc.), and other types of products, such as silicon steel, guardrail, steel sheet pile, etc.

The factory is located in Shandong, China, with a monthly output of 1,600 tons. We have rich export experience and strict quality control. Please feel free to contact us if you are interested.

Leave Us A Message

- Aluminum Fence Panel

- WPC Fence Panels

- Steel Reinforcement Mesh

- Galvanized Concrete Mesh

- Galvanized expanded metal mesh

- Brick reinforcing mesh

- Steel Reinforcement Bar

- PPGI Coil

- Galvanized Barbed Wire

- Black Annealed Wire

- Construction Binding Wire

- Steel Wire Rod

- Galvanized Razor Wire

- Low Carbon Steel Wire

- Galvanized Concertina Wire For Sale

- Steel Grating Plate

- Wire Mesh For Concrete Slab

- 430 stainless steel

- HRB400 Steel

- Q235 Steel

- DX51D