What Is Binding Wire?

Binding wire is also known as tying wire or tie wire. It is a kind of metal wire for bundling things in our daily lives or for fixing or connecting metal structures in industry and construction fields. The common material is Q195/Q235 Low Carbon Steel Wire. It is widely used in toy factories, handicrafts, gardening, construction, highway guardrails, product packaging, and other uses.

Ⅰ. Popular Wire Diameter

Wanzhi Steel offers a wide range of steel tie wires of gauge 6-24 in diameter. The most commonly used wire diameters include: gauge 21 (0.71 mm), gauge 20 (0.8 mm), gauge 18 (1.0 mm), gauge 16 (1.2 mm), gauge 14 (1.6 mm), and gauge 12 (2.0 mm). The most popular tying wire for reinforcement is in size gauge 21 (0.71 mm) and gauge 20 (0.8 mm).

Steel Tie Wire for Sale

Galvanized U-shaped Tying Wire

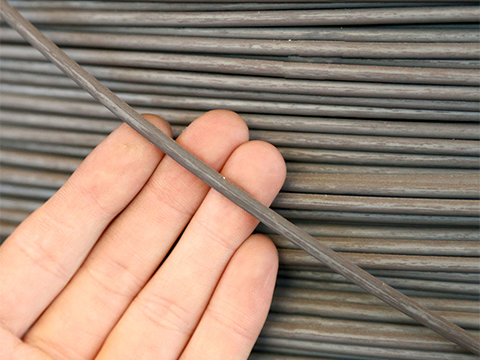

Annealed Wire Binding Surface

Ⅱ. Types of Binding Wire

It can be classified into three aspects: surface treatment, shape, and material, and there are the following types respectively.

1. Surface Treatment

According to the different surface treatment methods, there are:

1). Annealed steel tying wire

Black annealing treatment to provide a bright surface. Also, the annealed wire has good elasticity and flexibility. In order to prevent rust, you can apply anti-rust oil on the surface to maintain its service life.

2). Electro galvanized binding wire

Through electro-galvanizing, its surface is covered by a thin zinc layer, which makes it more corrosion resistant to prolongs its service life.

3). Hot-dip galvanized tie wire

It refers to coating steel wire with zinc by immersing the metal in a bath of molten zinc at a temperature of around 450 °C. The zinc coating thickness can reach up to 300 g/m2. So it provides better corrosion resistance than electro-galvanizing.

4). PVC or PE coated binding wire

This product uses galvanized wire as raw material and then applies a polyvinyl chloride (PVC) coating on the surface. The PVC coating makes the steel wire resistant to dirt, oil, salt, chemicals, UV rays, etc. so that its service life is up to 12 years. Also, it offers more color options, like green, black, yellow, white, etc.

Black Annealed Binding Wires

GI Binding Steel Wires

Green PVC Binding Wire

2. Different Materials

Besides, according to the different materials, it includes mild steel (MS) binding wire and stainless steel (SS) binding wire, etc.

1). MS binding wire uses low-carbon steel as a material. The plain steel wire is black. It is used to tie applications in construction uses, such as for tying the rebars.

To prolong its service life, it can be galvanized or PVC-coated. After galvanizing, it has a silver and smooth surface finish. Also, it has better corrosion resistance.

2). SS binding wire uses grades of 304 and 316 stainless steel as material. It provides the highest grade of corrosion resistance compared to other wires. Also, its price is higher as well.

Mild Steel Binding Wire

stainless steel tie wire

metal wire tie

3. Common Wire Shapes

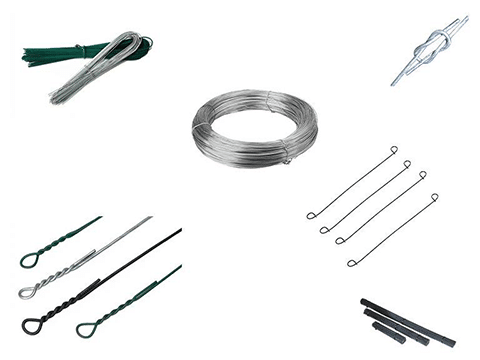

1. Cutting tie wire

As the name implies, it is straightened first, and then it is cut to a fixed length according to the customer’s requirements.

2. U Type wire

The U-shaped wire is ideal for binding steel rebars in the construction industry. Also, its length can be customized to better meet special projects.

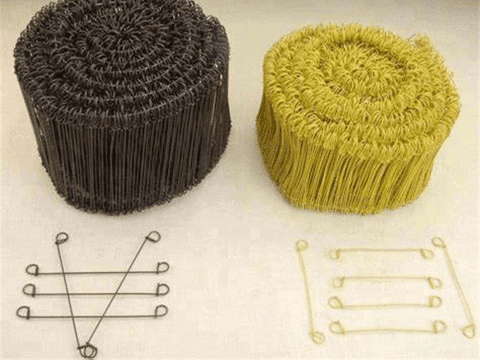

3. Loop wire ties

It contains single-loop ties and double-loop wire ties. The former has one loop and one straight end. The straight end allows the wire to be pulled tight around irregular bundles. Double-loop wire ties have a loop on each end, which more suits large, heavy loads of uniform size. They are ideal for steel rebar tying, bagging, and bundling.

4. Steel wire coil

It refers to a coil of wire. That is, wires are packaged in roll, including electro galvanized wire, hot-dip galvanized wire, mild steel binding wire, and PVC coated wire. The coil weight ranges from 10 kg to 1,000 kg.

If you have any questions about the size and type, please

consult our professional technicians and we will be happy to help you.

Cutting Tie Wires & Coil Wires

Galvanised Wire Ties

19 Gauge Max Tw1061t Annealed Tie Wire

Ⅲ. Common uses of binding wire

1. Twin loop wire binding, Book binding.

2. Binding steel bars, and fixing scaffolding.

3. Artwork decoration.

4. Fixing and connecting various components.

5. Binding cartons and crates.

6. Fixing orchard stands.

7. Making fences and hedges.

8. DIY handmade products.

Binding Wire in Construction

Different types of wire tying

DIY Garden trellis

Ⅳ. Wanzhi Binding wire specifications and process

Binding Wire Gauge 20, 18, and 16, galvanised and annealed.

450 gm per roll and 10 rolls per bundle.

900 gm per roll and 10 rolls per bundle.

Wire nails 1″ to 4″ gross weight 5 kg and net weight 3 kg.

Wire nails 1″ to 4″ gross weight 5 kg and net 2.5 kg.

100 × rolls (of 2000) Galv bag ties 250 mm × 1.6 mm.

20 × rolls (of 2000) Galv bag ties 200 mm × 1.6 mm.

Wanzhi Steel Hot-selling specifications

1. Aluminium binding wire 6 SWG & 8 SWG.

2. Binding wire of 18 and 20 SWG, in 10 kgs packing, with single opening and closing.

3. 18 gauge galvanised rebar binding wire. Double strand.

4. GI PVC Coated Binding Wire.

5. Steel low-carbonaceous wire with a diameter of 0.7-1.0 mm, tensile strength 1300-1500 MPa.

6. Annealed and galvanized binding wire for construction industry for binding the reinforcement.

7. Wire ties shall be 1.6 mm (16 gauges) or heavier black annealed steel wire.

8. Epoxy-coated grade 60 steel ASTM A775M, A615M.

9. Welding wire copper coated, 0.045 dia on 12″, spools, 33 pounds per spool.

10. Flat wire, tensile 3241 low carbon, .028 × 1/8 cut to 26 inch lengths or in spools. And round stitching wire.

11. High tensile steel strand 3 × 3 mm (three wire strand 3 × 3 mm dia each as per 1.s: 6006/83).

12. High strain wire 3.06 mm: mass zinc, lightly galvanized weighing 50 kg per roll.

13. Anchor wire 4.0 mm lightly galvanized weighing 50kg per roll.

14. Stainless steel binding wire (tie wire) grade SS 304 and SS 316 options 0.9 mm – 1.2 mm dia. for tying reinforcement steel at project.

15. 100 boxes. 9,10,11 & 12 gauge delivered per pallet. and cost per box.

PVC TIE WIRE

Ss tie wire Axis wire

PVC U-type Binding Wires

Ⅴ. How much binding wire is required for 1000 kg steel?

The amount of tying wire needed to tie 1000kg or 1 ton of rebar is as follows:

8mm – 12 kg – 13.5 kg

10-12mm – 10 kg

16-25mm – 8 kg

28-32mm – 7 kg

32-40mm – 4 kg

On the left is the diameter of the reinforcement in millimeters, and on the right is the number of tied wires, which depends on the size of the reinforcement and the complexity of the steel design.

For example:

There may be 10 mm diameters”, or 50 mm diameters. You may need to tie every 200 mm or every 5 meters.

It is advisable to consult the constructor or engineer to calculate and then approach the supplier to buy in bulk at the ex-factory price, which will result in significant cost savings.

For detailed information please read this article – How much binding wire is required for 1 ton steel?

Ⅵ. Package of Steel Binding Wire

Steel tying wires are often packaged in a certain length or weight, with plastic film inside and woven bags outside. Wanzhi Steel also offers custom packaging options according to your needs.

Bale packing ties for mentioned below

bales.

Height: 610 mm to 650 mm.

Width: 460 mm.

Length: 1270 mm.

Baling Wire Coil

.062″ to .375″ diameter.

Any: annealed, medium, or hard temper.

Binding wire 1.6 mm

1.6 mm in 25 kg coils.

Qty: 1 × FCL, approx 25 mt.

Binding Wire 20 gauge

Thickness: 20 Gauge.

Quantity:

A: 2.5 kg/per Roll – 1 × 20′ Feet Container.

B: 3 kg/per Roll – 1 × 20′ Feet Container.

C: 3.5kg/ Per Roll – 1 × 20′ Feet Container.

Annealed Binding Wire

U-shaped binding wire paper box package

double looped wire package

Ⅶ. Binding Wire Supplier – Wanzhi Steel

(1) Advanced Production & Mass Capacity: Fully automated high-speed drawing & annealing lines enable 24/7 production, with an annual output of 50,000+ tons.

(2) Quality Materials & Precision Sizing: Strictly use Q195/Q235 steel wire rods; wire diameter ranges 0.8mm-2.5mm with ±0.02mm tolerance for precision.

(3) Custom Solutions & Certified Quality: Offer annealed, galvanized, or black finish options; products are ISO 9001, SGS, and MTC certified.

(4) Global Logistics Support: Provide EXW/FOB/CIF trade terms, with 15-day fast delivery to meet global customer needs.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of annealed wire, galvanized wire, Baling Wire, low carbon wire, High tensile wire, galvanized binding wire, and galfan wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and excellent services, its products have been exported to over 120 countries worldwide.

Leave Us A Message