GAW and GBW Wire Mesh

GAW ( galvanized after welding) and GBW (galvanized before welding) refer to two processing techniques for galvanized wire mesh products. There are many differences between these two processes. Next, let’s find out.

Welcome to Ask Us For An Online Quote! (Chat on WhatsApp / Email Directly).

What Is GAW Welded Mesh?

The full name of GAW is galvanized after welding. It is formed when the wire is welded or woven into a mesh and then galvanized. The benefit of this process is that the zinc layer adheres tightly to the wire, allowing each wire to be protected. In addition, galvanizing the wire mesh after welding causes every vulnerable welded or woven area to be completely sealed. This makes GAW wire mesh ideal for any area that may come into contact with water and other corrosive substances. The following are the features of GAW wire mesh produced by Wanzhi Steel:

1. Welded or woven points are thoroughly galvanized;

2. Long service life – resistant to rust and corrosion;

3. Different sizes and dimensions of mesh are available.

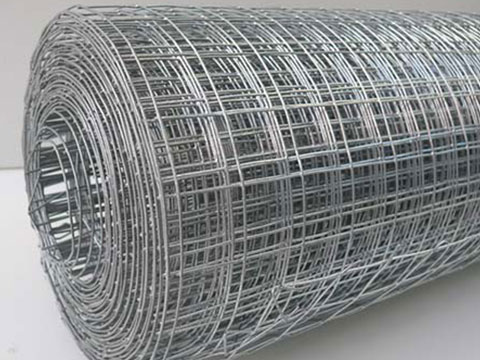

Galvanized After Welding

GAW Wire Mesh Roll

GAW Wire Mesh Processing Steps

1. Raw Materials

The main raw materials of GAW metal mesh are generally carbon steel wire, galvanized wire, stainless steel wire, etc.

2. Cold Rolling

Cold rolling is a metalworking process. Most of the wire used for welding is cold rolled wire. This is because the wire is cold rolled to increase its yield strength and hardness.

3. Straightening and Cutting

This step is carried out by a specialized machine. Firstly the cold rolled wire in coil condition is passed through the pre-set dies and barrel units in the straightening and cutting machine. Next, after the wire is straightened, it is then automatically cut to a set length (with an accuracy of up to 2 mm). It is also worth mentioning that the wire can be cut to any size.

4. Spot Welding

The most common welding process used for wire mesh production is spot welding. The wire is placed in a machine and welded by resistance, and a metal mesh is formed.

5. Bending and Cutting

Welded wire mesh can be bent and cut to suit the customer’s needs for different applications. Our factory is equipped with advanced bending and cutting machines. The bending machine can be used to bend the cut mesh into the desired shape. While the cutting machine is used to cut the finished mesh into the required size.

6. Galvanizing

After the bending and cutting process, the mesh will be galvanized. The entire mesh is placed in a “pool” of melted zinc so that it receives a protective layer. After the galvanizing process, the welded wire mesh will eventually become corrosion resistant.

High Quality GAW Wire Mesh

GAW Wire Mesh Panels

What Is GBW Welded Mesh?

The full name of GBW is galvanized before welding. It is the opposite of the GAW process. It is the process by which galvanized mild steel wire is woven or welded into wire mesh. But the GBW process has one drawback. That is that when the galvanized wire is welded, the zinc layer may be burned off, leaving the weld joint exposed and thus less resistant to corrosion. When woven together, pre-galvanized and post-galvanized provide a similar level of corrosion protection. The following are the characteristics of GBW wire mesh:

1. Economical;

2. Can be cut, formed, and welded;

3. Usually a low carbon steel alloy;

4. Magnetic in all conditions.

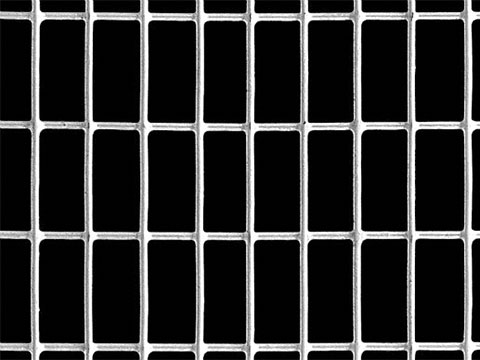

Galvanized Before Welding

GBW Features

GAW VS GBW Welded Wire Mesh

1. Anti-corrosion Properties

Wire mesh made by the GAW process generally has better corrosion resistance than GBW. This is because welding first and then plating will allow every corner of the mesh to be evenly coated with zinc. Whereas plating before welding destroys the zinc layer at the welded joints, which leaves some areas on the mesh without the galvanized protection against rust and corrosion.

2. Service Life

When GBW wire mesh is used outdoors, it becomes susceptible to rain or other corrosive liquids. Rust and corrosion will begin to eat away at the wire, shortening its life. While GAW wire mesh is strong enough to resist corrosion and can be used in a variety of environments. It also lasts longer than GBW wire mesh.

3. Price

The cost of GBW wire mesh is lower compared to GAW. This is because the GBW process is simpler. In addition, the GBW process produces a mesh that is less resistant to corrosion than GAW, which is why it is less expensive. Therefore, if you want an inexpensive mesh with moderate service life, GBW is the ideal choice.

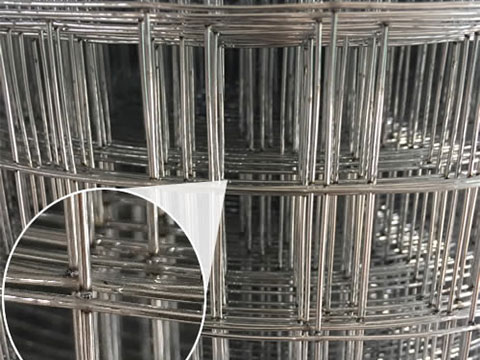

Wire Mesh in Wanzhi

Steel Wire Mesh for Sale

Which Type Should I Choose?

Wanzhi Steel offers both processes of wire mesh and a wide range of sizes to choose from. When you don’t know what to choose, you can judge according to the actual use and budget. In addition, you can also ask us for help. As a leading wire mesh manufacturer in China, our experienced sales managers will provide you with practical solutions. Contact us now for more details!

Welcome to Request an Online Quote!

WhatsApp: 8613938459717(Click To Directly Chat)

Email: info03@wanzhisteel.com(Click To Email Me)

Leave Us A Message