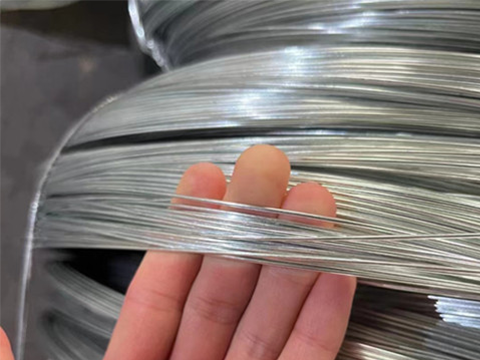

Spring Steel Wire

Material: Carbon steel(Q195/Q235/Q235B/Q345/Q345B, SAE1008/SAE1040/SAE1045/SAE1070/SAE1080, 72A/72B/77B/82B), galvanized steel, SS steel

Wire Diameter: 0.3-10mm

Supply form: Coils/compact bundles, spools

Surface finish: Bright, bright shiny, fat-free, slightly oiled

Wire Shape: Round, oval

Spring Steel Wire

Spring wire is a unique and versatile material with exceptional properties such as very high yield strength, elasticity, and resilience. Its composition and heat treatment processes set it apart from regular steel, making it ideal for various applications, including springs, clips, fasteners, and machinery. It plays an important role in controlling mechanical motion and absorbing vibration and shock energy in a wide variety of ways. As a professional spring steel wire manufacturer, Wanzhi Steel stocks a large number of common specifications and accepts customization of all sizes and shapes. You are welcome to contact us.

Cold rolled spring wire

galvanized spring wire

Stainless spring wire

Spring Steel Wire Specification

| Item | Spring steel wire |

| Place of origin | Hebei, China |

| MOQ | 5 Tons |

| Treatment conditions | Final annealed, semi-hard drawn, and hard-drawn |

| Surface Treatment | Galvanized (optional) |

| Type | Drawn Wire(Cold pull) |

| Hardness level | SL, SM, SH, and DH, formerly known as classes A, B, C, and D. |

| Payment Methods | TT 30% prepaid |

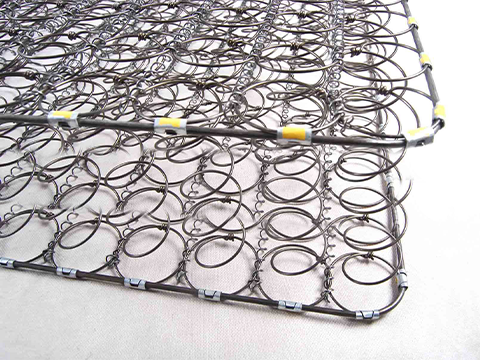

| Application | Making mattress springs, all kinds of springs |

| Delivery period | 7-14Days(Excluding transportation time) |

| Sample | Avaibale |

| Packing | PVC film and PP snake skin bag |

| Coil Weight | 25kg, 50kg, 100kg, 200kg, 300kg |

| Transportation | By sea, by land |

What is spring steel?

Spring steel is an assembly of various steel materials. We use it to make springs, especially in automotive and industrial suspension applications. The high elastic limit is achieved by a special alloy containing silicon, manganese, chromium, vanadium, molybdenum, and nickel. The tensile strength is obtained by a final heat treatment. The materials include various types, including precipitation hardened steel and nickel alloy, stainless steel wire, galvanized steel wire, high carbon steel, other alloy steels, etc.

coil spring wire

spring steel manufacturers

Key features of spring steel wire

- High elastic limit: Spring steel wire has a high elastic limit, which means that it can deform significantly under stress and return to its original shape after the stress is removed.

- High tensile strength: It can withstand heavy loads without breaking or permanently deforming. This makes it ideal for applications that are subject to high stress.

- Good fatigue resistance: Spring steel wire has excellent fatigue resistance, and it can withstand repeated loading and unloading cycles without significant performance degradation.

- Ductility and toughness: Spring steel wire has high strength, good ductility, and forgeability, making it easy to form into various shapes and sizes during the manufacturing process.

- Corrosion resistance: The surface can be treated with zinc plating, nickel plating, phosphating, etc., to improve rust resistance, suitable for humid or corrosive environments.

- Density and thermal properties: The density is 7.85 g/cm³, which takes into account both lightweight and strength. Ordinary spring steel has a temperature resistance of about 120℃, and heat-resistant steel (such as 50CrVA) can withstand temperatures above 300℃.

- Formability: Easy to cold draw, cold roll, or hot form, can be processed into precision springs (micro springs for electronic equipment) or large springs (shock-absorbing springs for engineering machinery).

High Tensile Wire for Sale

house wiring spring

Chemical and physical properties

Spring steel chemical composition table (typical grades)

| Steel type/standard grade | C (%) | Si (%) | Mn (%) | Cr (%) | V (%) | Other Elements | Implementation Standards |

| High carbon spring steel (SAE 1080 / EN C75S) | 0.70–0.90 | 0.10–0.35 | 0.60–1.00 | ≤0.30 | – | P≤0.040%, S≤0.050% | ASTM A401 / EN 10089 |

| Silicon manganese spring steel (SAE 9254 / 60Si2MnA) | 0.56–0.64 | 1.50–2.00 | 0.60–0.90 | ≤0.35 | – | P≤0.035%, S≤0.035% | GB/T 1222 / JIS G4801 |

| Chrome vanadium spring steel (SAE 6150 / 50CrV4) | 0.48–0.55 | 0.15–0.35 | 0.70–1.00 | 0.80–1.10 | 0.15–0.25 | P≤0.025%, S≤0.025% | DIN 17221 / ASTM A682 |

| Stainless steel spring steel (AISI 302 / SUS304) | ≤0.15 | ≤1.00 | ≤2.00 | 17.0–19.0 | – | Ni: 8.0–10.0% | ASTM A313 / JIS G4314 |

Table of physical properties of spring steel (typical values after heat treatment)

| Steel type/standard grade | Tensile strength (MPa) | Yield Strength (MPa) | Elongation(%) | hardness (HRC) | Elastic modulus (GPa) | Fatigue limit (MPa) | Main features |

| High carbon spring steel

(SAE 1080) |

1600–1900 | 1400–1700 | 5–8 | 44–50 | 200–210 | 600–800 | High rigidity, low cost |

| Silicon manganese spring steel (60Si2MnA) |

1800–2200 | 1600–2000 | 6–10 | 48–54 | 205–215 | 700–900 | High fatigue life, impact resistance |

| Chrome vanadium spring steel (50CrV4) |

1900–2300 | 1700–2100 | 8–12 | 50–56 | 210–220 | 800–1000 | High temperature resistance, anti-relaxation |

| Stainless steel spring steel (AISI 302) |

1500–1800 | 1300–1600 | 10–15 | 40–48 | 190–200 | 500–700 | Corrosion resistance, medical/food grade application |

What is spring steel used for?

1. Major categories:

- Compression springs, tension springs, torsion springs.

2. Specific applications:

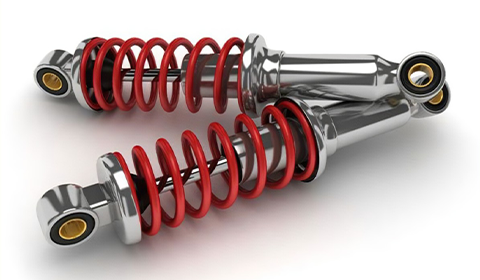

- Vehicle parts, internal combustion engines, clutches, etc.

- Hardware accessories

- Surgical tools, orthodontic appliances

- Spiral strapping, conveyor belts, and sieves

- Landing gear for small aircraft

- Clock and watch parts

compression coil spring

- Switches, bayonet lamp holders, nuts

- Lock picking tools

- Spring clip

- Battery conductive sheet connections, gaskets

- Piano wire, also known as music wire

- Knives, machetes, and other blades

- Manufacturing round-bladed swords

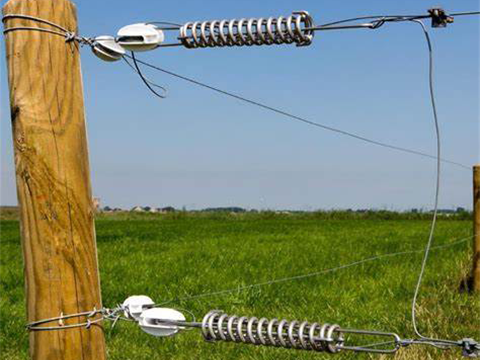

- Mattress springs, door springs, race fence springs

- Vehicle coil springs or leaf springs

Switch Ss spring

Faq

Is spring steel the same as music wire?

Music wire is made of spring wire. They are all iron alloy wires. Because spring wire has many grades, the yield strength is also different. For example, music wire contains a higher proportion of chromium, grade ASTM A228, so it has better tensile strength. In addition to piano wire, its applications include spring clips, antennas, S-shaped forks, and clutch plates.

Can I heat spring steel?

If you want to bend it you need to heat it until it glows red and it loses its hardness. Then it slowly cools and it doesn’t harden again and you can treat it the same way you would normal steel.

What is the maximum temperature for spring steel?

Using stainless spring steels has ballooned in recent years. Several new compositions are now available to withstand corrosion. We can use these materials for high temperatures up to 650°F.

Is spring steel good for cutting?

1075 Blue Temper Spring Steel is a versatile steel that isn’t just for springs, clamps, and coils. Therefore, we often use it in blade-making as well. It’s able to hold its edge well and is receptive to sharpening.

spring wire steel

compression coil spring

spring for wire pulling

Can you bend spring steel?

If the cross section is small and the steel used is not very hard, it can be directly cold-bent. If the cross section is large or the hardness is high, the steel can be annealed and then cold bent, or heated to red hot and then hot bent, and then quenched and tempered. The specific process depends on the grade of steel, because different steels require different heating temperatures and quenching media, as well as different tempering curves.

Does spring steel lose strength when heated?

Excessive heat exposure can cause serious damage to technical springs, then leading to loss of function or failure. For example:

– Springs made from steel alloys may lose tensile strength after prolonged high-temperature exposure.

– Elastomeric materials used for some types of seals degrade over time at elevated temperatures.

– The lifespan of electrical control switches utilizing small metallic springs decreases significantly at higher ambient temperatures due to metal fatigue.

astm a228

spring wire steel

Is spring steel the same as carbon steel?

| Spring steel | VS | Carbon steel |

| 0.5% – 1.0% | Carbon content | 0.05%-2.0% |

| Excellent elasticity and resilience | Mechanical properties | Good strength and ductility |

| Corrosion resistance | Corrosion resistance | Susceptible to corrosion |

| Structural components, mechanical parts, and other general applications | Applications | Specially used for springs, wires, and other parts requiring high elasticity and resilience |

| >Carbon steel, <Alloy steel | Price | Economical |

How long does spring steel last?

If a tension spring is subjected to forces greater than it is designed to withstand, it will be irreparably damaged and may break. Avoiding overstretching and limiting the deformation of oil tempered springs to less than 25% of their total length will extend their service life.

Here is Spring Wire’s life expectancy on average:

- Standard Cycle Springs: 10,000 cycles.

- High Cycle Springs: 25,000 cycles.

- Highest Cycle Springs: 50,000 cycles.

B27 high carbon spring steel

astm a313

Measures to prolong the service life of springs

- At first, keep it lubricated continuously and choose a mild, non-corrosive lubricant.

- Then, keep the environment dry.

- At last, be careful not to come into direct contact with other metals.

- Then, balance the spring wire every few years to prevent it from tensile fatigue.

Generally, a spring will not break within a year. If it breaks, it may be due to substandard materials, defects, aging, or improper use and installation. Therefore, it is important to choose a reputable factory that provides a warranty for the spring and obtains ISO certification.

Common spring steel-grades

- 17-7PH Nickel Coated Spring Wire ASTM A313, AMS 5678

- 17-7Ph Stainless Spring Wire

- Type 302 Stainless Steel Wire

- Type 304 Stainless Steel Wire

- Type 304 Stainless Steel Wire – Nickel Coated

- 304VM

- Type 316/316L Stainless Steel Wire

- 316LVM

- AISI 316

- AISI 316Ti

We can harden and temper many grades of steel to increase their elasticity and resistance to deformation; however, some steels are inherently more elastic than others:

stainless steel spring wire

spring wire suppliers

| SAE grade (ASTM grade) |

Composition | Yield strength | Hardness (HRC) | Comments | |

| Typical | Maximum | ||||

| 316(A313) | – | 222,000 psi | Mirror-Like, Matte | ||

| 1065(A229) | – | 195,000 psi | Oiled, Matte | ||

| 1070 | 0.65-0.75% C, 0.60-0.90% Mn, max .050% S, max .040% P | Normally supplied annealed | 165vpn | 180vpn | CS70, CK67, C70E |

| 1074/1075 | 0.70–0.80% C, 0.50–0.80% Mn, max. 0.030% P, max. 0.035% S | 62–78 ksi (430–540 MPa) | 44–50 | 50 | Scaleless blue, or Polished Bright |

| 1080 (A228) | 0.7–1.0% C, 0.2–0.6% Mn, 0.1–0.3% Si | – | – | – | Piano wire, music wire, springs, clutch discs |

| 1095 (A684) | 0.90–1.03% C, 0.30–0.50% Mn, max. 0.030% P, max. 0.035% S | 60–75 ksi (410–520 MPa), annealed | 48–51 | 59 | Blue, or polished bright spring steel |

| 5160 (A689) | 0.55–0.65% C, 0.75–1.00% Mn, 0.70–0.90% Cr | 97 ksi (670 MPa) | – | 63 | Chrome-silicon spring steel; fatigue-resistant |

| 50CrV4 (EN 10277) | 0.47–0.55% C, max. 1.10% Mn, 0.90–1.20% Cr, 0.10–0.20% V, max. 0.40% Si | 170 ksi (1,200 MPa) | – | – | Old British 735 H1steel, SAE 6150, 735A51 |

| 9255 | 0.50–0.60% C, 0.70–0.95% Mn, 1.80–2.20% Si | – | – | – | – |

| 301 spring-tempered stainless steel |

0.08–0.15% C, max. 2.00% Mn, 16.00–18.00% Cr, 6.00–8.00% Ni | 147 ksi (1,010 MPa) | 42 | Equivalents EN 10088-2 1.4310, X10CrNi18-8 | |

Surfaces & Package

Standard Package

Package for Sale

Surfaces

Wanzhi Steel offers the surfaces bright, shiny, fat-free, as well as epq-quality, bright, slightly oiled, soap-coated, pickled-phosphate, pickled, and coated. We supply straight spring wire and flat spring steel wire, Stainless spring wire, carbon steel spring wire, flexible spring wire, fine spring wire, high carbon spring wire, as well as spring steel wire mesh and spring steel wire rods…

Packagings

Wanzhi packagings include manufacturing coils/ compact bundles, spider carriers, spooled coils, drums, spools, bars, and threaded bars.

Shipping

production line of spring steel wire

spring steel wire manufacturer near me

Wanzhi Steel- Reputable Spring Wire Manufacturers

Wanzhi Steel in China stocks spring wire in different diameters and grades, and accepts custom sizes. Welcome to browse our factory online. We will also provide you with factory-direct prices based on your quantity and product specifications.

Need help or get a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized wire, low carbon wire, barbed wire, SS wire, concertina razor wire, Cold drawn wire, spring steel wire, galfan wire, and PVC Coated Galvanized Wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message