Crimped Wire Mesh

Crimped wire mesh is also called Crimped Woven Wire Mesh. It is a heavy-duty mesh that is woven by a weaving machine after being crimped. Also known as space cloth. Wanzhi Steel is a reputable supplier of crimped wire mesh in China. We provide crimped wire mesh of various materials, such as galvanized wire, annealed wire, 45#/65# manganese steel, SUS 304/316/304L/316L stainless steel wire, and accept customized sizes. If you have special requirements, welcome to contact us!

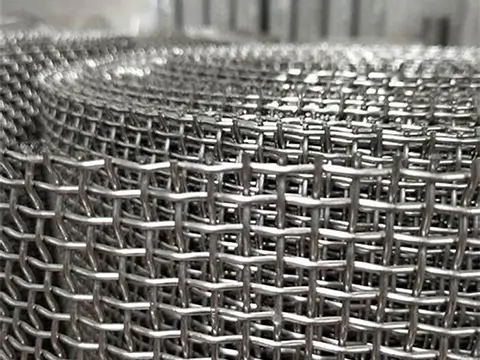

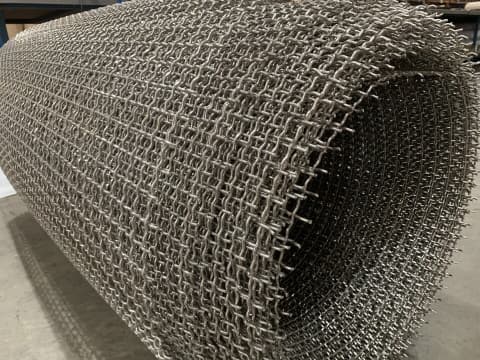

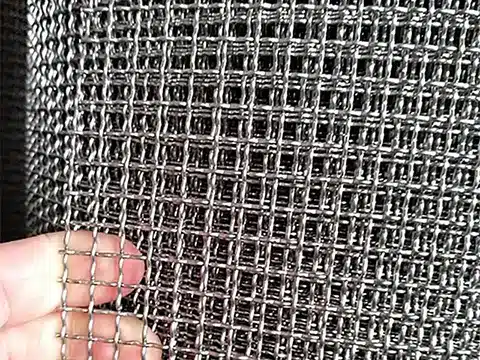

stainless steel crimped wire mesh

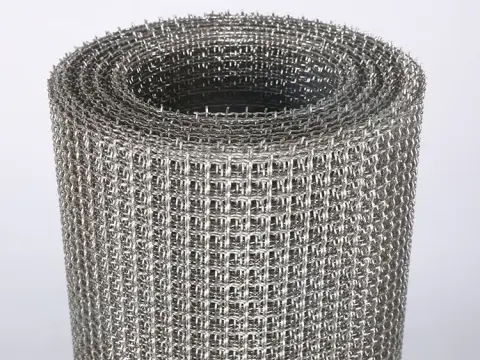

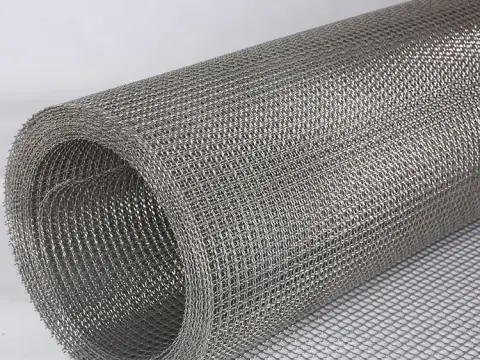

Roll of wire mesh

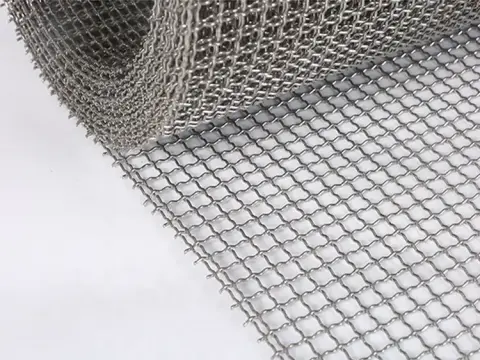

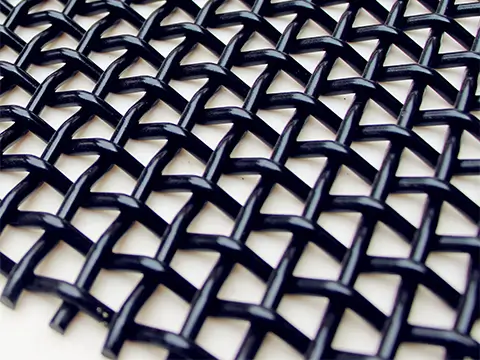

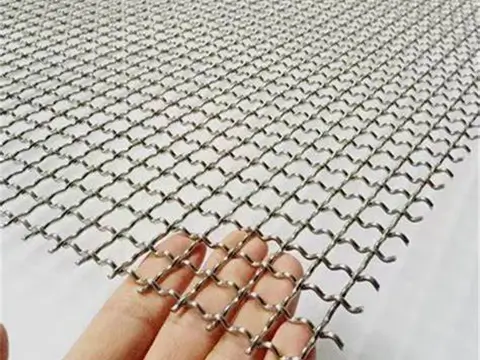

lock crimp wire mesh

Crimped Wire Mesh Specification

| Item | Crimped Wire Mesh |

| Place of Origin | Hebei, China |

| Delivery Time | 8-14 days |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Woven Mesh |

| Material | Stainless steel wire, galvanized steel wire, Q195/Q235 low carbon steel wire |

| Hole types | Diamond, square, rectangular |

| Wire diameter | 1.0-12m |

| Width | 1m, 1.2m, 1.5m |

| Length | 20, 30, 50m/roll, customized |

| Opening size | 1.5-6mm |

| Mesh | 2 – 635 mesh |

| Porosity | 56% – 94.1% |

| Crimping patterns | Double crimp, lock crimp, intermediate crimp |

| Color | Silver |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons |

| Transportation | By sea, by land |

What is crimped wire mesh?

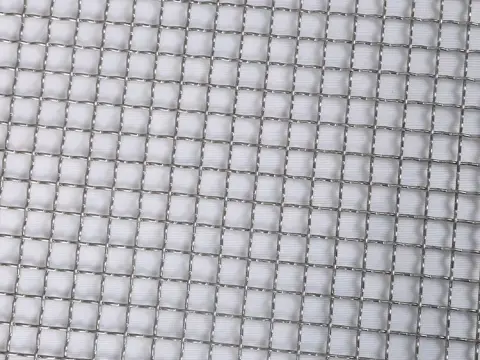

Crimped wire mesh (also known as space cloth) is a woven wire mesh that is formed by bending before forming. It is available in a variety of materials and weaving methods, with beautiful textures and forms as a whole. Its tight weaving allows it to withstand greater pressure and tension while also being aesthetically pleasing and not easily deformed or damaged. It is widely used in architectural applications as filler panels, cages, and decorations. It is also used in acoustics, filtration, bridge guardrails, aerospace components, rodent control, and truck grilles.

galvanized crimped wire mesh

pre crimped wire mesh

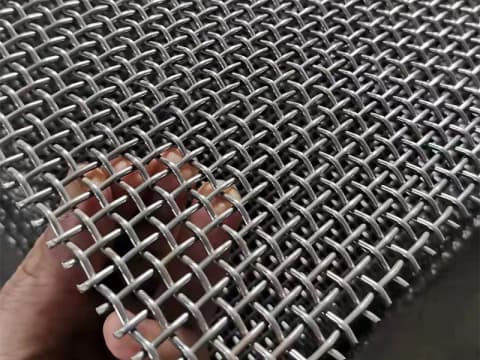

steel crimped wire mesh

Crimped Wire Mesh Benefits

1. High strength: The corrugated structure enhances the tensile strength and wear resistance of the mesh surface, and is not easily deformed by stretching or extrusion due to external forces, and it is suitable for load-bearing or protective scenarios.

2. Stable pores: The weaving process makes the mesh size precise and can maintain a stable particle separation effect during screening or filtering.

3. Durability: Made of materials such as stainless steel and galvanized iron wire, the surface is not easy to rust, and is suitable for harsh environments such as humidity, acid, and alkali. High toughness and good impact resistance, it can resist impact and wind impact.

4. Processing and adaptability: The wire diameter, mesh size, material, and surface treatment (galvanizing, painting) can be customized according to needs to adapt to different scenarios.

5. Convenient installation: Lightweight, moderate flexibility, easy to cut, weld, or splice, such as fence installation, equipment protective cover production.

6. Multi-function: Efficient screening and filtration, regular mesh and not easy to clog, suitable for ore, sand, and gravel classification or liquid/gas impurity filtration.

7. Cost-effectiveness: Compared with complex woven mesh, the process is simple and durable, cost-effective, and suitable for batch use.

8. Easy maintenance: The surface is smooth and easy to clean, highly rust-proof after anti-corrosion treatment, and not prone to dust and scaling, with low maintenance costs.

double crimped wire mesh

Stainless steel crimped woven cloth mesh

gi crimped wire mesh

Material Characteristics Of Crimped Wire Mesh

1. Mild Steel / Low Carbon Steel Wire: This wire has a carbon content of less than 0.20%, has good formability and ductility, and can withstand moderate bending or flattening.

2. Black wire: Black steel wire, also known as high carbon steel wire with greater hardness. With added manganese, it is called high manganese crimped wire mesh with increased wearing resistance. Commonly used in the mining screen mesh. Common manganese steel used:45 # Mn, 65 # Mn.

3. Galvanized wire: Applied to crimped wire mesh with a small wire diameter, used to make wire mesh barbecue.

4. Galvanized Redrawing Wire: Compared with galvanized steel wire, the redrawing wire has one timeless annealing process as detailed below:

The average galvanized wire production process is Rod – Drawing – annealing – drawing – annealing – galvanized.

The redrawing wire production process is Rod – Drawing – Annealing – Zinc Plating – Drawing.

As a result of the processing difference, the galvanized redrawing wire has more strength compared with common galvanized wire, poorer corrosion resistance, and costs less.

5. Stainless steel wire: Commonly used 304, 316, 304L, 316L grades. The Stainless steel wire is a high-performance steel wire. Because it has different specifications and models. Therefore, it is a silk product with a round or flat cross-section. Known for its good corrosion resistance and high-cost performance.

Different sizes and materials

PVC Woven mesh

Crimped wire mesh surface

Where Is Crimped Wire Mesh Used?

1. Industry: used in the mining and metallurgical industries to screen ores, sand and gravel, and other materials; in the chemical industry such as raw material purification, as liquid/gas filter media, equipment protective covers, and pipeline dust nets.

2. Building protection & reinforcement: used as wall plastering nets and insulation layer fixed nets to prevent cracking; used for highway guardrails, construction site safety nets, or courtyard isolation fences.

3. Agriculture and breeding scenarios: making breeding cages such as chicken cages and pig pens, or greenhouse insect nets, used as escape prevention nets or seedling screens in aquaculture.

4. Mining and tunnel engineering: screening ore in mining vibrating screen equipment, and combining with concrete to reinforce rock walls when supporting mine tunnels.

5. Garden and landscape decoration: used as garden fences, plant climbing frames, tree reinforcement nets, or garden hollow decorative nets, flower bed protection nets.

6. Household daily use: barbecue nets, kitchen range hood filters, household insect screens, etc.

woven wire mesh

mesh woven

Fence

How Is Crimped Wire Mesh Made?

1. Wire selection: Select stainless steel wire, galvanized iron wire, aluminum wire and galfan coated wire according to the purpose, and determine the wire diameter.

2. Pretreatment: Degrease the wire and clean the surface of the oxide layer. If galvanizing or plastic coating is required, pretreatment can be completed at this stage.

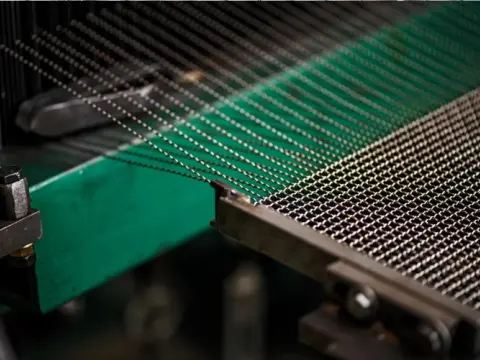

3. Pressing & bending: Apply pressure to the wire through the Crimping Machine to produce regular corrugated bends (crimped) to form a “wavy” cross-section. Adjust the roller spacing and pressure to control the height and spacing of the corrugations.

4. Weaving & forming: Cross weaving, arrange the bent wires in a vertical cross-shaped manner, and interweave them through an automatic crimping machine. Through mechanical extrusion or welding, the intersection of the warp and weft wires is fixed to form a stable mesh surface.

5. Size cutting & shaping: Cut to a specified width and length. Commonly used tools include shearing machines and laser cutting machines. A leveling machine or manual machine is used to eliminate deformation during the weaving process and ensure flatness and uniform mesh.

6. Surface treatment: optional, anti-corrosion treatment such as galvanizing, plastic spraying, chrome plating, anodizing, polishing, wire drawing, and other processes to improve the appearance. Or high temperature resistance and anti-static treatment.

7. Quality inspection & packaging: Check mesh accuracy, wire diameter error, surface defects, tensile strength, etc., to ensure compliance with standards. Roll into mesh rolls or cut into flat plates according to specifications, package with moisture-proof materials, mark the model, and put into storage

crimped wire mesh manufacturers

mesh woven machine

Galvanized steel crimped mesh

Wanzhi Crimped Wire Mesh Sizes

1. Galvanized Steel crimped woven mesh screen

| Mesh | SWG | Wire Dia (mm) | Aperture(mm) | SIZE ROLL: 50FT/100FT |

| 10.7mm | 14 | 2 | 10 | 4FT ROLL |

| 1″ | 10 | 3 | 25 | 4FT X 8FT |

| 1″ | 10 | 3 | 25 | 4FT ROLL |

| 1.5″ | 10 | 3 | 40 | 4FT ROLL |

| 1/2″ | 10 | 3 | 12.7 | 4FT X 8FT |

| 1/2″ | 10 | 3 | 12.7 | 4FT ROLL |

| 1/2″ | 14 | 2 | 12.7 | 4FT ROLL |

| 1/2″ | 10 | 3 | 12.7 | 4FT X 8FT |

| 2″ | 6 | 5 | 50 | 4FT X 8FT |

| 2″ | 4 | 6 | 50 | 4FT X 8FT |

| 2″ | 8 | 4 | 50 | 4FT X 8FT |

| 2″ | 8 | 4 | 50 | 4FT ROLL |

| 3/4″ | 10 | 3 | 20 | 4FT ROLL |

| 3/4″ | 14 | 2 | 20 | 4FT ROLL |

| 5/8″ | 14 | 2 | 15 | 4FT ROLL |

Stainless steel crimped mesh

crimped woven wire mesh

Annealed wire crimped wire mesh

2. Stainless steel crimped woven mesh screen

| Mesh | SWG | Wire Dia (mm) | Aperture(mm) | SIZE ROLL: 50FT/100FT |

| 9mm | 10 | 3 | 9 | 4FT ROLL |

| 10mm | 14 | 2 | 10 | 4FT ROLL |

| 10.7mm | 14 | 2 | 10 | 4FT ROLL |

| 1″ | 10 | 3 | 25 | 4FT ROLL |

| 1″ | 10 | 3 | 25 | 4FT X 8FT |

| 1.5″ | 10 | 3 | 40 | 4FT X 8FT |

| 2″ | 6 | 5 | 50 | 4FT X 8FT |

| 1/2″ | 10 | 3 | 12.7 | 4FT X 8FT |

| 1/2″ | 10 | 3 | 12.7 | 4FT ROLL |

| 1/2″ | 14 | 2 | 12.7 | 4FT ROLL |

| 1/2″ | 16 | 1.5 | 12.7 | 4FT ROLL |

| 1/2″ | 16 | 1.5 | 12.7 | 30″ ROLL |

| 3/4″ | 10 | 3 | 20 | 4FT X 8FT |

| 3/4″ | 10 | 3 | 20 | 4FT ROLL |

| 3/4″ | 14 | 2 | 20 | 4FT ROLL |

| 5/8″ | 14 | 3 | 15 | 4FT ROLL |

crimped wire mesh manufacturer

Galvanized mesh roll for sale

low carbon steel mesh panel

Crimped Mesh One-Stop Supplier – Wanzhi Steel

If you are looking for a woven mesh that is both beautiful and durable, then crimped metal wire mesh must be your best choice.

Wanzhi Steel has rich experience in manufacturing and exporting. With a factory of more than 1,000 square meters, we can take bulk orders at the same time and deliver quickly. Our products are of excellent quality and meet international export standards. Over the years, we have always treated every batch of goods with care. If you want to know the price, please contact us by email or online, and we will reply to you within 8 hours.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Galvanized Wire Mesh Roll, Galvanized Welded Wire Mesh, Galvanized Wire Mesh Screen, SS welded wire mesh, and Galvanized Steel Hardware Cloth for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message