Coated High Tensile Wire

Coated high tensile wire refers to a steel wire that is coated with one or more layers of material on the surface of the high-tensile steel wire, through a specific process to improve its corrosion resistance, wear resistance, or other specific properties. It is widely used in bridge cables, construction, automobiles, aerospace, power transmission, and communications. Wanzhi Steel specializes in the production of high-tensile wire and accepts a variety of surface treatment processes such as galvanizing and plastic coating. If you have special requirements, we will definitely meet all your requests.

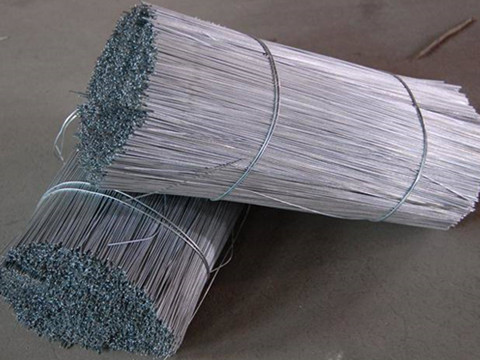

Galvanized Wire

Cold drawn GI spring Wire for wire bundling

green pvc coated wire

Coated High Tensile Wire Specification

| Item | Coated High Tensile Wire |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Material | Carbon Steel, SS steel, Hot-dipped galvanized steel |

| Coating type | Zinc, Zinc Aluminum, Plastic (PVC, PE, Vinyl) |

| Steel Grade | Q195/Q235/SAE1006/SAE1008 |

| Color | Silver or customized |

| Coil weight | 1kg, 5kg, 10kg, 20kg, 25kg, 50kg, 500kg |

| Wire Gauge | 0.2mm-5.5mm |

| Zinc Coating | 12-240g/m2 or as customer’s request |

| Tensile strength | 300~550 N/mm2 |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Elongation rate | 10%-30% |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Available |

| Price Item | FOB, CIF, EXW, etc |

| Packing | Spool or coil wrapped with moisture-proof paper or plastic film. |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Transportation | By sea, by land |

What is Coated High Tensile Wire?

As mentioned above, in order to increase the durability of high tensile wire, the coating process is usually adopted, and coated high-strength steel wire is a high-tension steel wire with coating on the surface to improve its corrosion resistance and wear resistance. Common coating types include galvanized coating, zinc-aluminum alloy coating, PVC coating, etc.

Green PVC Coated GI Wire Manufacture

galfan wire manufacturers

Q195/Q235 low carbon wire for Nail Making

In addition, high-strength and high-quality carbon structural steel wire materials such as SWRM52A are also often used to manufacture various steel wires, steel strands, etc. It has good strength and toughness, as well as excellent weldability and machinability. Its chemical composition mainly includes C (0.49%~0.56%), S (0.15%~0.35%), Mg (0.30%~0.60%), and a small amount of phosphorus and sulfur (both not exceeding 0.03%).

What is the high tensile wire?

High-strength steel wire is made by drawing carbon steel or alloy steel. It contains alloy elements such as Fe, C, Si, Mn, etc. It has excellent strength and toughness and can withstand large tensile forces. This kind of steel wire is usually used in application scenarios that require high strength and durability. Its production steps usually also involve heat treatment or coating processes to enhance its strength and durability. It has advantages in working in high-strength and high-temperature environments, such as automobile engine compartments, boilers, etc.

Characteristics of Coated High Tensile Wire

1. High strength: Coated high-strength steel wire has excellent tensile strength and yield strength, which can meet the strength requirements of various structures.

2. Lightweight: Despite its high strength, high-strength steel wire is relatively light, which is convenient for handling, transportation and installation, especially in large projects.

Steel Wire Supplier

High Tension 316l Stainless Wire Supply

High Quality Straight Steel Wire

3. Good toughness: Even under extreme conditions, the steel wire can maintain sufficient toughness and is not easy to break.

4. Corrosion resistance: The coating can effectively isolate the steel wire from direct contact with the environment and extend its service life.

5. Wear resistance: Some coatings can also provide additional wear resistance, reducing the wear of the steel wire during use.

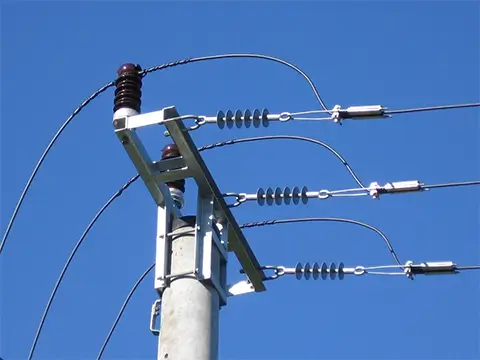

Where is coated high tensile wire used?

1. Bridge cables and slings.

2. Building structure support and suspension.

3. Power transmission conductors, ground wires, overhead wires.

4. Agricultural fences and livestock fences.

5. Support drilling equipment, fix pipelines, and create temporary or permanent structures.

6. Vehicle and aircraft parts.

Farm fence

high tensile stainless steel wire

Coated Cable Horse Fence

How many coating types of Coated High Tensile Wire?

1. Hot-dip galvanized coating

A uniform zinc layer is formed on the surface of the steel wire through the hot-dip galvanizing process, providing excellent corrosion resistance.

2. Zinc-aluminum alloy coating

Combining the advantages of zinc and aluminum, it has higher corrosion resistance and weather resistance, suitable for harsh environments.

3. Organic coating

Such as epoxy resin, polyurethane, etc., provides additional wear resistance, chemical corrosion resistance, and aesthetics.

4. PVC coating/polyethylene coating

Through plasticized coating, it can not only provide a colorful appearance, but also make it resistant to sunlight, long-lasting and non-fading, and decorative.

BWG21 green PVC coated HDP cut binding wire

10 ga Zinc Aluminum Alloy Wire

Q235 q195 high tensile galfan coated wire

Common Colors And Wire Gauges

1. Common Colors

Common colors on the market include white coated high tensile wire, black coated high tensile wire, and green. For example, 12.5 gauge white safety coated high tensile horse fence wire is lightweight but can withstand animal impacts. It will not cause scratches to livestock like barbed wire, and can also withstand extreme temperature conditions. In addition, poly fences also often use this type of color and material.

2. Common Gauges

It is sometimes used as high tensile steel cable and high-tensile wire rope. Commonly used ones are 10 gauge, 14 gauge high tensile wire, 4mm high tensile galvanised wire, 3mm high tensile wire, and the 12.5 gauge mentioned above.

High Tensile Wire vs. Low Strength Steel Wire

1. First of all, their processes are different, and the production of low-strength steel wire is relatively uncomplicated.

2. Secondly, the hardness and strength of high-strength steel wire are higher than those of low-strength steel wire, but its ductility and plasticity are not as good as those of low-strength steel wire.

3. In addition, in terms of use, high-strength steel wire is suitable for bridges, railways, electricity, cableways, and other fields, while low-strength steel wire is used in occasions with low strength requirements, such as fences, protective nets, agriculture, and light industry.

4. Finally, in terms of price, the price of high-strength steel wire is higher than that of low-strength steel wire.

high tensile galvanized wire

vinyl coated renault mattress

Vinly coated galvanized iron wire

What is coated high tensile steel wire made of?

Its base material is the carbon Steel Wire Rod. After stabilization, pickling, copper plating, or phosphating, it can be made into carbon steel with different carbon contents. It can also be made into alloy steel after adding other elements. Then it is hot rolled, cold drawn, and made into high-strength steel wire. Then it is galvanized or plastic coated to form coated high-strength steel wire, such as poly coated high tensile wire, vinyl coated high tensile wire, or Galvanized high tensile wire. Zinc Aluminum Alloy high tensile wire.

Wire Rod Coil

Zinc aluminum alloy wire production line

Tensile strength test

Is high carbon steel wire a high strength steel wire?

No, they are different in many ways, which can be summarized as follows:

Chemical composition

1. High carbon steel wire usually contains more than 0.6% carbon, while the carbon content of 80 steel reaches 0.7%~0.9%. The high carbon content gives it higher hardness and strength.

2. High-strength steel wire is not characterized by high carbon content. Instead, it may use an alloying treatment or process to improve strength.

Mechanical properties

1. High carbon steel wire has high hardness, high elastic limit, and fatigue limit after heat treatment or cold drawing, but its welding performance and cold plasticity are poor, and it is easy to break and has high brittleness.

2. High strength steel wire has excellent mechanical properties, including high strength, high toughness, and good wear resistance.

Application areas

1. High carbon steel wire is used to make tools, knives, springs, bearings, and other parts that need to withstand high stress and wear.

2. High strength steel wire is used to make frames, doors, chassis, springs, strengthen building structures, bridges, fences, etc.

Manufacturing Process

1. High carbon steel wire is processed by hot rolling, cold drawing, heat treatment, and other processes.

2. High strength steel wire includes multiple steps such as alloying, heat treatment, special drawing, etc., which is relatively complicated.

tensile wire for sale

GI wire for sale

PVC Coated Galvanized Wire Coils

Coated High Tensile Wire Supplier – Wanzhi Steel

✅ Advanced Equipment: A fully automatic cold-drawn production line is adopted to ensure high precision and consistency.

✅ Rich Material Selection: Low carbon steel, high carbon steel, galvanized steel, and stainless steel are available.

✅ Customized Service: Supports customization of diameter, surface treatment, plastic coating thickness, and color.

✅ Fast Delivery: With a large inventory of regular diameters and a 1,000 square meter workshop, we can meet bulk orders at the same time.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001 certified steel mill located in Hebei Province, China. For 14 years, Wanzhi Steel has been specializing in the production of galvanized wire, low carbon wire, stainless steel wire, PVC coated wire, and galfan wire, with a monthly output of 1,800 tons. With high-quality products and good services, the products have been exported to more than 120 countries around the world.

Leave Us A Message