Black Annealed Wire

Black annealed wire is a low-carbon steel wire that has been annealed to form a dark blue-black oxide film. It is soft, tough, ductile, easy to bend, and inexpensive. It is commonly used for bundling, tying wire, and crafts. It is suitable for temporary or internal structural applications where rust protection is not a priority. Wanzhi Steel is a professional annealed and tempered wire manufacturer in China. We stock a large number of conventional diameters and provide customization services. Our products have been used in many national projects. If you are interested, please contact us.

Annealed Steel Wire

Annealed wire mesh black

Black Annealed Wire Specifications

| Item | Black Annealed Steel Wire( Annealed Iron wire) |

| Place of Origin | Hebei, China |

| Feature | Soft, good toughness, high ductility, easy to bend and process, low cost |

| Tensile Strength | 350- 550 N/mm2 |

| Type | Drawn Wire |

| Surface | Annealed, with oil |

| Standard | ASTM/AISI/JIS/GB/DIN/BS |

| Color | Black |

| Coil Weight | 10-800 kg or as per your requirements |

| MOQ | 5 tons |

| Payment term | 30% TT Advance + 70% Balance |

| Sample | Free available |

| Packing | Standard Sea-worthy Packing |

| Uses | Binding wire, making handicrafts, and wire mesh, etc. |

What Is Dark Annealed Wire?

Annealed wire is a soft iron wire product made of low carbon steel through cold drawing, heating, constant temperature, heat preservation, and other processes. It is often packaged into coils, spools, or further straightened and cut into cutting wire, U-shaped wire, etc.

Inner Packaging

close view of black Annealed wire

Features

- Soft texture: Annealing treatment changes the crystal structure inside the iron wire, eliminates internal stress, has good ductility, can be easily bent and wound, and can meet the processing of complex shapes.

- Surface oxidation treatment: A black oxide film is formed on the surface during the annealing process, which has a unique appearance, provides certain rust and corrosion resistance, and prolongs life.

- Easy to process: It is easy to cut, bend, and weave, and has good welding performance. Through appropriate welding technology, it can be firmly connected with other metals, which is convenient for making various metal products or structural parts.

- Low price: Compared with stainless steel wire, copper wire, and other metal wires, the production cost is lower, and it is highly competitive in cost-sensitive fields.

- Strength and toughness: Although it is soft, it can still withstand a certain amount of tension and pressure, and can play a reliable role in scenes with low strength requirements.

- Diverse specifications: Common wire numbers range from 5# to 38#, and the corresponding wire diameter ranges from 0.17mm to 4.5mm, which can meet the needs of various industries.

Reinforcement Binding Wire

Hanger

Fencing

Annealed Wire Export Case

Extensive Uses

Application of different wire diameters

- Fine wire: 0.16 mm- 0.6 mm, commonly used for fine work such as binding and weaving.

- Medium wire: 0.6 mm- 2.0 mm, suitable for scenes such as building binding, packaging fixation, etc.

- Coarse wire: 2.0 mm- 5.0 mm, used in heavy binding, agricultural fences, and other occasions that require high strength.

Recommended wire diameter for different uses

- Construction industry: Common wire diameter is 0.7 mm- 2.0 mm, used for binding steel bars, fixing scaffolding, etc.

- Agriculture: Common wire diameter is 1.5 mm- 3.0 mm, used for making fences, building greenhouses, etc.

- Industrial packaging: Common wire diameter is 0.5 mm- 1.0 mm, used for bundling goods, fixing pallets, etc.

Application scenarios

- Construction: During the concrete pouring process, steel bar tying is used to fix the steel bars. Tying scaffolding steel pipes, making wire mesh, building enclosures, protective nets, etc.

- Agriculture: Fixing greenhouse frames and covering materials. Making fences for livestock and dividing farmland. Tying crops to prevent lodging.

Handicrafts

Basket

Hay Baling Wire

- Industrial packaging: Tying goods in logistics transportation, fixing goods on pallets, and making packaging tape.

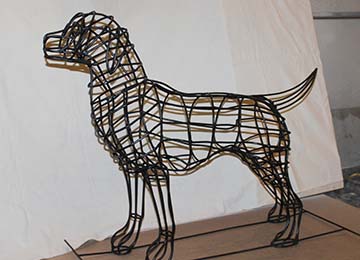

- Handicrafts: Making woven handicrafts such as wire flowers and animal sculptures. Home DIY, such as making bookshelves, hooks, hangers, etc.

- Others: Gardening, fixing plants, building flower stands, etc. Making fishing nets, repairing fishing gear, etc. Mine support, fixing equipment, etc.

Types of Annealed Wire

Classification by material

- Carbon steel annealed wire: This is the most common type of annealed wire. It uses high-quality carbon steel as raw material. It has good toughness and processing performance. It can meet general use needs and is widely used in construction, agriculture, industry and other fields.

- Stainless steel annealed wire: Made of stainless steel, it has excellent corrosion resistance, high temperature resistance and oxidation resistance. It is often used in industries with strict requirements on hygiene and corrosion resistance, such as food processing, medical equipment, and chemicals.

black annealed tie wire

annealed stainless steel wire

black annealed binding wire

Classification by surface treatment

- Bright annealed wire: The surface is not specially treated to maintain the gloss of the wire itself. Bright annealed wire has good electrical and thermal conductivity and is used in occasions where the appearance requirements are not high, but good electrical properties or thermal conductivity are required.

- Galvanized annealed wire: A layer of zinc is plated on the surface of the annealed wire to improve its corrosion resistance. Galvanized annealed wire is widely used in outdoor environments. The zinc layer can effectively prevent the wire from rusting and extend its service life.

- Plastic-coated annealed wire: The surface of the annealed wire is coated with a layer of plastic, such as polyethylene, polyvinyl chloride, etc. Plastic coated annealed iron wire has good insulation, corrosion resistance, and aesthetics. It can not only protect the iron wire from corrosion, but also play a decorative role.

Annealed Cutting Wire

BWG21 green PVC coated cut wire

Soft Annealed Wire

The black annealed wire manufacturing process

1. Roll a hot metal billet into a thick steel bar, that is, a wire rod.

2. After rust removal and pickling, the wire rods will be drawn into wires of different diameters through drawing equipment.

3. Cool down and anneal it at a high temperature. Then apply oil to prevent it from rusting before packaging for sale.

Does Black Annealed Wire Rust?

Yes, but the rusting of annealed wire does not necessarily affect the strength of the wire. Its surface is often coated with anti-rust oil to make it more durable. You can also choose annealed wire with a zinc protective layer or PVC coating on the surface to extend its service life. Wanzhi Steel sells both.

wire rod suppliers

Black Annealed Twisted Wire

Advantages of the Annealing Process

Annealing is a process of heat treatment in which the metal is slowly heated to a certain temperature and held for a while, and then cooled at a suitable speed. Then why annealing?

(1) Reduce hardness and improve machinability, to improve the flexibility and ductility of the wire itself, and further increase the tensile strength.

(2) Eliminate residual internal stress and reduce deformation and cracks, making the steel wire easier to bend, stamp, and perform other processes.

(3) To reduce the defects of material structure to improve its properties for further heat treatment.

Can you anneal the stainless steel wire?

Yes, stainless steel wire can also be annealed. Annealing is a heat treatment process that involves heating the material to a specific temperature and then slowly cooling it to change its microstructure. Such as cold drawing, heating, constant temperature, insulation, and annealing softening.

Annealed Wire Production Line

Wanzhi Steel Drawing wire Equipment

Does annealing weaken steel?

No, it just improves its performance. Which metal wires can be annealed? Annealing can actually soften many metals, such as brass, steel, iron, copper, and silver. All of them can be softened by heating the metal to a set temperature and slowly cooling it down, which can produce softer and more conductive products.

Wanzhi Steel Processing Video

Differences Between Galvanized Wire & Annealed Wire

- The main features of galvanized wire are corrosion resistance and silver surface. Due to different galvanizing processes, it is divided into hot-dip galvanized wire and electro-galvanized wire. It is made of low-carbon wire rod through drawing, pickling, rust removal, high-temperature annealing, galvanizing, cooling, and other processes. Good toughness and elasticity.

- The main feature of annealed wire is softness, and the surface is black after anti-rust oil is applied. It uses low-carbon wire rod as raw material, and is made through pickling, rust removal, drawing, high-temperature annealing, and other processes. It has the characteristics of strong toughness and good plasticity.

| Wire Gauge | SWG in mm | BWG in mm | Metric System mm |

|---|---|---|---|

| 6# | 4.87 | 5.15 | 5.00 |

| 7# | 4.47 | 4.57 | 4.50 |

| 8# | 4.06 | 4.19 | 4.00 |

| 9# | 3.66 | 3.76 | – |

| 10# | 3.25 | 3.40 | 3.50 |

| 11# | 2.95 | 3.05 | 3.00 |

| 12# | 2.64 | 2.77 | 2.80 |

| 13# | 2.34 | 2.41 | 2.50 |

| 14# | 2.03 | 2.11 | – |

| 15# | 1.83 | 1.83 | 1.80 |

| 16# | 1.63 | 1.65 | 1.65 |

| 17# | 1.42 | 1.47 | 1.40 |

| 18# | 1.22 | 1.25 | 1.20 |

| 19# | 1.02 | 1.07 | 1.00 |

| 20# | 0.91 | 0.89 | 0.90 |

| 21# | 0.81 | 0.813 | 0.80 |

| 22# | 0.71 | 0.711 | 0.70 |

| 23# | 0.61 | 0.635 | 0.60 |

| 24# | 0.56 | 0.559 | 0.55 |

| 25# | 0.51 | 0.508 | 0.50 |

| 26# | 0.46 | 0.457 | 0.45 |

Black annealed wire storage

Black Annealed Wire to Turkey

Black Annealed Wire Factory-Wanzhi Steel

Choose black annealed wire for everyday bundling and baling tasks—its flexibility reduces hand fatigue and increases efficiency. Our wire is uniformly soft and easy to spool. Wanzhi Steel offers volume discounts and fast shipping. Our factory boasts over 100 advanced wire drawing and mesh weaving machines, as well as testing instruments. As a global trading company, our multilingual sales team is well-established, ensuring we can always provide you with customized solutions at competitive prices.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001 certified steel mill located in Hebei Province, China. The company specializes in the production of GI wire, galfan wire, SS steel wire, zinc aluminum alloy wire, low carbon iron wire, binding wire, and baling wire. With 14 years of experience, the monthly output reaches 1,800 tons. With high-quality products and good services, the company’s products have been exported to more than 120 countries around the world.

Leave Us A Message