IS 2062 is the Indian Standard for Hot Rolled Low, Medium and High Strength Structural Steels, The IS 2062 standard specifies the composition, physical properties, dimensions, profiles, and quality of the steel. All finished steels shall be rolled to the required dimensions and profiles and shall be free from harmful defects such as blemishes, delamination phenomena, roughness/jaggedness, and imperfect edges. The following section describes the significance of the standard, the specified chemical composition, mechanical properties, and characteristics.

Steel Channel, Grade Is 2062 at best price

Steel IS2062 E350 Flat Bright Bar

structural steel h beam

What is the meaning of IS 2062?

IS 2062 is an Indian Standard for hot rolled low, medium, and high strength structural steel. The standard covers various types of steel including micro-alloyed steel plates, strips, forms and bars (angles, profiles, beams and channels, etc.), flats, and bars used in structural construction. These steels are suitable for welded, screwed, and riveted structures and general engineering construction. Among them, IS 2062GrB is a high-quality sedum steel, widely used in various fields such as construction, bridge, ship, vehicle, machinery manufacturing, etc. It has good strength, plasticity, and toughness, and at the same time is easy to process and weld.

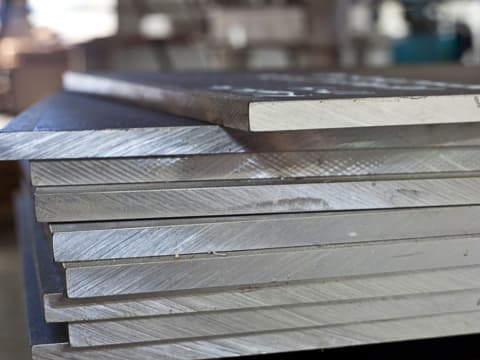

IS 2062 plate specification

| Item | IS 2062 plate |

| Grade | IS 2062 Gr B |

| Width | 1500/1250/2000/1800/2500 mm |

| Thickness | 3/16″-24″ |

| Size | 2000mm*1000mm up to 4000*2000mm |

| Manufacture technique | Hot Rolled, Cold Rolled |

| Surface Finish | 2D,Hot rolled plate(HR), BA NO(8), 2B, SATIN, Cold rolled sheet |

| Testing | PMI Inspection, Destructive Testing, Non Destructive Testing |

Is2062 E350bo Plate

IS2062 STEEL ROUND BAR

IS 2062 chemical composition

The IS 2062 standard has strict rules for the chemical composition of steel. Taking E250B grade as an example, the maximum values of chemical composition (mass fraction %) are as follows:

1. Carbon (C): 0.22 percent

2. silicon (Si): 0.4%

3. Manganese (Mn): 1.5 percent

4. Phosphorus (P): 0.045 percent

5. Sulfur (S): 0.045 percent

The last character of the grade indicates the quality grade of the steel, e.g. B for B grade.

In addition, the carbon equivalent (CE) has a corresponding limit, for E250B grade, its carbon equivalent should be ≤ 0.41%.

is2062-stress-chart

IS 2062 Grade B mechanical property

The IS 2062 standard also specifies the requirements for the mechanical properties of steel.

Taking E250B grade as an example, its mechanical properties are as follows:

1. When thickness t<20mm, tensile strength σb≥410MPa, yield point σs≥250MPa, elongation at break or elongation δ%≥23.

2. When thickness 20≤t≤40mm, tensile strength σb≥410MPa, yield point σs≥240MPa, elongation or extension after break δ%≥23.

3. When thickness t>40mm, tensile strength σb≥410MPa, yield point σs≥230MPa, elongation or extension after break δ%≥23.

BS 970 709 M40 Round Bar Supplier

International Equivalent Grade for IS 2062 Steel Plate

The commonly used and common equivalent grades are listed below:

EN 10025 (93)

S275J0

EN 10025 (90)

Fe 430C

NFA 35-501

St 44-3U

E28-3

DIN 17100

BS 4360

43 C

is 2062 hot rolled structural steel pipe

What is IS 2062 Grade B?

IS 2062 Grade B is a low-carbon structural steel. Its chemical composition includes carbon, manganese, sulfur, phosphorus, and silicon.IS 2062 Grade B plates have good strength and corrosion resistance and perform well under different temperature and pressure conditions. Mild steel IS 2062 GR.B plates usually have carbon content between 0.05% and 0.25%. These mild steel plates are more ductile and weldable.

IS 2062 Cold and hot rolled Process

This grade can be both hot and cold rolled. Steel IS 2062 hot rolled plates are processed by heating the metal to over 1700 degrees F. These plates have a scaled surface and are easy to form and work on. gr. B IS 2062 MS cold rolled plates are processed at room temperature after the hot rolling process. These plates have excellent strength and superior surface finish compared to IS 2062 gr. B hot rolled plates.

Hot Rolled Steel Coil, Material Grade IS2062

IS 2062 E250 BR Plates, Thickness5 mm

IS 2062 L steel angle steel hot rolled

What is IS 2062 Gr.B Plate temperature range?

Grade 2062 steel has high strength and a temperature range of 650 to 720 degrees.

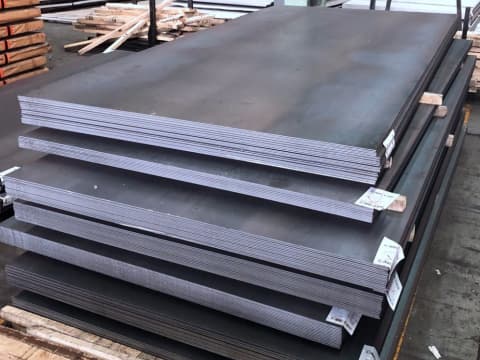

Most Popular Types of IS 2062 Grade B Plate

IS 2062 Plate

IS 2062 Chequered Plate

IS 2062 MS Plate

IS 2062 Grade B Plate

IS 2062 Steel Plate

IS 2062 Hot Rolled Plate

What is the difference between IS 2062 Grade A & B?

| IS 2062 Gr B | IS 2062 Gr A | |

| Carbon % | 0.22 | 0.23 |

| Impact Test | At 0 Degree | At Room Temp |

| Weldability | Low as Compared to A | High |

IS 2062 E250 – Fe 410WB Steel Sheet

IS 2062 E250BR Mild Steel Plates SUPPLY CHINA

IS 2062 Grade B Plate and GB Q235B steel

IS 2062 Plate Thickness Chart

| Thickness | |

| (mm) | |

| 1.2 mm | 1.3 mm; |

| 0.6 mm | 0.25 mm |

| 0.75 mm | 0.35 mm |

| 0.5 mm | 0.2 mm |

| 0.7 mm | 0.3 mm |

| 0.9 mm | 0.4 mm |

| 0.8 mm | 0.55 mm |

| 1.1 mm | 0.45 mm |

| 1 mm | 0.65 mm |

What is Hardness Of IS 2062 Plate ?

With reference to the carbon content in the chemical composition stated above, the hardness of low or medium carbon IS 2062 plate ranges from 120HBW to 131HBW.

IS 2062 Grade B Plate and GB Q235B steel

Factory Steel Plate IS2062 E250 E275 BR B0 C

Carbon Checkered Diamond Plate Q235B

Is the IS-2062 MS plate corrosion resistant?

1). IS 2062 mild steel Cr plates: The mild steel IS 2062 plates have medium tolerance to crevice corrosion and pitting by acids in harsh environments.

2). Mild steel Is 2062 plates: The mild steel Is 2062 plates also have good tolerance to crevice corrosion and pitting by acids in harsh environments.

3). Is 2062 Ms plates: have good mechanical properties and work well in oxidizing environments.

Benefits and applications of IS 2062 steel

IS 2062 steel plate inherits the various qualities of the alloying elements.

Advantages

It is very high strength and excellent corrosion resistance.IS 2062 chequered plate has high durability, ductility, and stability in elevated temperature conditions.

Applications

Multi-purpose grade carbon steel IS2062 GR.B plate is used in automobiles, decorative items, furniture, fencing, structural steel, and more.

standing seam metal roof

building structure

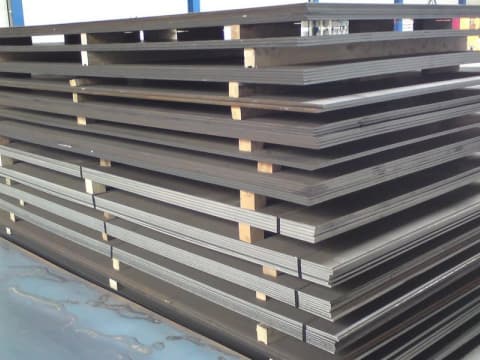

What are IS 2062 plate sizes?

| IS 2062 Standard Plate Size | |

| Thickness | Weight(kg/㎡) |

| 3 | 23.55 |

| 4 | 31.40 |

| 5 | 39.25 |

| 6 | 47.10 |

| 8 | 62.80 |

| 10 | 78.50 |

| 12 | 94.20 |

| 15 | 117.75 |

| 20 | 157.00 |

| 25 | 196.25 |

| 30 | 235.50 |

| 35 | 274.75 |

| 40 | 314.00 |

| 45 | 353.25 |

| 50 | 392.50 |

Supply A wide range of IS 2062 grade steel sheets are available to meet customer needs, including IS 2062 gr. B hot rolled and cold rolled sheets.

IS2062 Mild Steel Rectangular Flat Bar

Structural Steel H Beam, For Construction, Grade IS2062

IS 2062 Steel plate/coil/tube/wire For sale

Wanzhi Steel specializes in the production of IS2062 plates, coils, strips, sections (H, U, I, W), channels, flat steel, angle steel, wire rods, steel wires, and rebars. With high-quality products and excellent services, it has exported to more than 120 countries around the world.

Get the Price of IS 2062 gr.b plate

| Size | Price in USD |

| 6mm IS 2062 Grade B Plate | US $ 1.09 – 1.82/Kg |

| Hot Rolled, IS 2062 Gr B Plate | US $ 1.52- 1.88/Kg |

| 8mm IS 2062 Grade B Plate | US $ 1.46 – 1.88/Kg |

| IS 2062 grade b galvanized steel plate (1250 * 25mm) | US $309.24/Pcs |

Note: Since prices are variable, for accurate, up-to-date pricing, please contact an online professional.

With over 14 years of specialized experience in exports, Wanzhi Steel boasts a seasoned technical department and a multilingual sales team.

Our engineers stand ready to tailor solutions to your specific needs, offering competitive

pricing, top-notch quality, and a stellar reputation. Do not hesitate to chat with Wanzhi Steel

or send an Email to info03@wanzhisteel.com for any assistance you may require.

MS steel plate package

is2062 coil standard package

steel wire package ss316

Worldwide equivalents of grade IS2062 (India: IS )

| Country | Standard | Grade |

| India | IS | IS2062 |

| EU | EN | S275JR (1.0044) |

| USA | – | A283D, A529, Gr.D |

| Germany | DIN,WNr | RSt42-2, St 44-2 |

| Japan | JIS | SS400 |

| France | AFNOR | E28-2 |

| England | BS | 161-430, 43A, 43B |

| Canada | HG | 260W, 260WT |

| European old | EN | Fe430B |

| Italy | UNI | Fe430B |

| Belgium | NBN | AE295B |

| Spain | UNE | AE225B |

| China | GB | Q225A, Q275Z |

| Sweden | SS | 1411, 1412 |

| Poland | PN | St4V |

| Czechia | CSN | 11425 |

| Finland | SFS | Fe44B |

| Austria | ONORM | St42FSt430B |

| Norway | NS | NS12142 |

| Russia | GOST | St4ps, St4sp |

| Inter | ISO | E275B |

| Portugal | NP | FE430-B |

European equivalent grade for Non-alloy quality structural steel IS2062 (IS ): S275JR (1.0044)

Chemical composition and properties of European equivalents (EN) for IS2062 (India, IS ): S275JR (1.0044), IS2062 (India, IS ) – European (EU, EN), and worldwide Steel equivalent grades.

This comparison table is only intended as an indication of the closest known equivalent grades.

The source standards should always be checked for the specific purpose for each material, in case of doubt.

If you have other questions, don’t hesitate to Get In Touch With Us.

( Inquire Online or send an email to Info03@wanzhisteel.com.)

Leave Us A Message