Fences are available in a variety of materials, the most common of which are vinyl coated and galvanized. The Galvanized chain link fence features a coating on its surface that is silvery in color, which improves the durability of the fence. Vinyl coated chain link fencing is also made of metal, however, it is coated with vinyl instead of zinc. When you are ready to buy, you may be torn between the two of them. Next, Wanzhi Steel takes you through a review of what the differences are between these two different materials of fencing. (Chat on WhatsApp / Email Directly)

Galvanized Chain Link Fence

Vinyl Coated Chain Link Fence

What Is Galvanizing?

Galvanizing is a surface treatment technique in which iron or steel is coated with a layer of zinc for aesthetic and rust prevention purposes. Zinc is a highly corrosion-resistant metal that insulates iron from oxygen and water so that it cannot undergo the chemical reactions required to rust. The main methods of galvanizing are hot dip galvanizing (HDG) and electro galvanizing (EG).

What Is Galvanized Chain Link Fence?

Galvanized chain link fence is generally processed from electro-galvanized wire or hot-dip galvanized wire. The chain link fence can be coated before or after weaving. After galvanizing, the fence will be more durable and can last 20 years or more. The galvanized chain link fence produced by Wanzhi Steel can be used for stadium fencing, animal fencing, road green belt protection fencing, gabion fencing, etc.

Advantages

1. Cost-effective. Galvanized fence is a more economical choice compared to PVC coated fence.

2. Long life span. It can last for decades or more, and you don’t need to replace it as often.

3. Versatile. Galvanized fence is the first for most people. It is the more classic hook-and-loop fence. Whether it is used in a residential area or an industrial area, it is suitable.

Disadvantages

1. Slightly less durable. It wears out a little faster when exposed to harsh environmental conditions.

2. The appearance is rather homogeneous. The galvanized fence only has a silver appearance. If you are looking for a higher aesthetic, then galvanized chain link fence may not be the best choice.

GI Fence

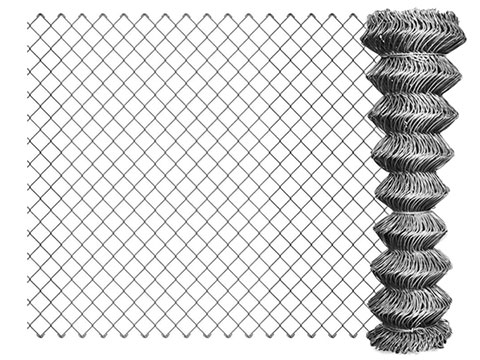

Galvanized Chain Link Mesh Rolls

What Is Vinyl Coating?

Vinyl coating is a type of coating consisting of synthetic resin or plastic. It is a thin protective layer of a substance that is deposited or applied to the surface of an object. It is primarily intended to improve its performance and to create a protective barrier against surface deterioration due to the reaction of the object to its environment.

What Is Vinyl Coated Chain Link Fence?

Vinyl coated chain link fence is highly resistant to corrosion and durability. Fences made of this material will rust or break down more slowly. In addition, this type of chain link fence is available in different colors that can add color and character to the fence.

Advantages

1. Durable. The metal wire is encased in a protective layer of vinyl that does not rust or break away easily.

2. More attractive. Vinyl coated fence is available in a variety of colors, such as green, red, yellow, white, black, etc. It can be applied to different occasions and make it look more attractive.

3. Customizable. You can customize different styles of vinyl hook fences for different occasions.

Disadvantages

1. Expensive. Vinyl-coated fences are generally more expensive than galvanized fences. If you don’t have much of a budget, vinyl coated is not the best choice.

2. Coating breakage. Although vinyl coating is strong, it can break under certain circumstances, especially when scratched by sharp objects. Once the coating is damaged, it speeds up the rate at which it ages.

Black Vinyl Chain Link Fence

Green Vinyl Coated Mesh Roll

Conclusion

As seen above, there are differences in performance, price, and appearance between Galvanized chain link fences and vinyl coated chain link fences. However, both types of fences are very popular.

Wanzhi Steel manufactures both types of fencing products and guarantees quality. We look forward to discussing your fencing needs with you. You can also find more information about our products on our website. Contact us today for more details.

WhatsApp: +86 13938459717 (Click To Directly Chat)

Email: info03@wanzhisteel.com (Click To Email Me)

Leave Us A Message