Zinc Aluminum Alloy Wire

Tensile strength: 1290 MPa – 1340 MPa

Main use: Binding wire, baling wire, construction tie wire, wire mesh, gabion box

Zinc Aluminum Alloy Wire

Zinc aluminum alloy wire is a new type of anti-corrosion material. It has the characteristics of strong adhesion, good wear resistance, and corrosion resistance. Compared with zinc wire and pure aluminum wire, it has stronger performance. Wanzhi Steel has many years of experience in the production of zinc-aluminium wire. In addition, we have a complete production line and production management system to ensure the quality of zinc aluminum alloy wire. If you are looking for this kind of metal wire for your project, you can contact us for more details.

Zinc Aluminum Alloy Wire

Zinc Wire

Zinc Aluminum Alloy Wire Specification

| Item | Zinc Aluminum Alloy Wire |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Material | Zinc Aluminum alloy |

| Chemical Composition | 85% Zinc 15%Aluminum, 90% Zinc 10%Aluminum, 95% Zinc 5%Aluminum |

| Shape | Round wire |

| Color | Bright silver |

| Density(g/cm3) | 7.14 |

| Melting Point(℃) | 419 |

| Processing Services | Plastic coating(PVC, Vinyl, PE), welding, woven |

| Coil weight | Samll coil 0.35kg/8Kg/25Kg; Big coil 50Kg/100Kg/500kg, or customized |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Avaliable |

| Price Item | FOB,CIF,EXW,etc |

| Packing | Spool or coil wrapped with moisture-proof paper or plastic film. |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Transportation | By sea, by land |

zinc aluminum coating wire

Galvalume Wire Stock

Common Wire Gauge and Diameters Table

| Gauge | SWG | BWG | AWG | |||

| Inch | mm | Inch | mm | Inch | mm | |

| 5 | 0.212 | 5.385 | 0.220 | 5.588 | 0.182 | 4.621 |

| 6 | 0.192 | 4.877 | 0.203 | 5.156 | 0.162 | 4.115 |

| 7 | 0.176 | 4.47 | 0.180 | 4.572 | 0.144 | 3.665 |

| 8 | 0.159 | 4.046 | 0.165 | 4.191 | 0.129 | 3.264 |

| 9 | 0.144 | 3.658 | 0.148 | 3.759 | 0.1144 | 2.906 |

| 10 | 0.128 | 3.215 | 0.134 | 3.404 | 0.1019 | 2.588 |

| 11 | 0.116 | 2.946 | 0.12 | 3.048 | 0.0907 | 2.305 |

| 12 | 0.104 | 2.642 | 0.109 | 2.769 | 0.0808 | 2.053 |

| 13 | 0.092 | 2.337 | 0.095 | 2.413 | 0.072 | 1.828 |

| 14 | 0.08 | 2.032 | 0.083 | 2.108 | 0.0641 | 1.628 |

| 15 | 0.072 | 1.829 | 0.072 | 1.829 | 0.0571 | 1.45 |

| 16 | 0.064 | 1.626 | 0.065 | 1.651 | 0.0508 | 1.291 |

| 17 | 0.056 | 1.422 | 0.058 | 1.473 | 0.0453 | 1.15 |

| 18 | 0.048 | 1.219 | 0.049 | 1.245 | 0.0403 | 1.024 |

| 19 | 0.04 | 1.016 | 0.042 | 1.067 | 0.0359 | 0.912 |

| 20 | 0.036 | 0.914 | 0.035 | 0.839 | 0.032 | 0.812 |

Zinc Aluminum Alloy Wire Composition Table

| Chemical composition(%) | Standard value | Measured value |

| Zn | 84~86 | 85.274 |

| Al | 14~16 | 14.6 |

| Cd | ≤0.005 | 0.002 |

| Cu | ≤0.01 | 0.001 |

| Fe | ≤0.05 | 0.02 |

| Pb | ≤0.005 | 0.003 |

| Si | ≤0.12 | 0.1 |

| Total | ≤0.17 | 0.126 |

Features

- Excellent corrosion resistance: Combining the advantages of zinc and aluminum, it can provide long-term protection in harsh environments. Especially in marine climates, high humidity or corrosive media, its corrosion resistance is better than pure zinc or pure aluminum materials, and its service life is 2-3 times that of galvanized wire.

- Good mechanical properties: It has high strength and ductility, and can withstand large mechanical stress without breaking easily. Its elongation at break is high, which is suitable for application scenarios that require bending or winding, such as cable sheaths, braided nets, etc.

High Quality Steel Wire

Finished Product

- Low melting point and easy processing: The melting point of zinc-aluminum alloy is relatively low, which is convenient for processing into wires of different diameters and shapes (round wire, flat wire) through casting, extrusion, cold drawing, rolling, and other processes. Meet the diverse needs of plating, weaving, welding, etc.

- High and low temperature resistance: The oxidation resistance at 200℃ is better than that of pure zinc, and the aluminum oxide film can inhibit the volatilization of zinc and maintain the stability of the material; it still maintains toughness in low temperature environments below -40℃, and is not easy to break brittlely, which is suitable for application in severe cold areas.

- Excellent coating performance: Common thermal spraying or electroplating processes can form a dense protective layer on the surface of the substrate. The coating has good adhesion and uniformity, which can prevent corrosion of the substrate. It can also be further passivated and painted.

- High cost-effectiveness: Compared with pure zinc or pure aluminum materials, zinc-aluminum alloy wire can reduce material costs while maintaining excellent performance. Its long life and low maintenance requirements further improve the overall cost-effectiveness and are suitable for large-scale applications.

- Good electrical and thermal conductivity: Suitable for application scenarios that require electrical connections or heat dissipation, such as electronic components, radiators, etc.

- Customizability: The zinc and aluminum composition and processing technology of zinc-aluminum alloy wire can be adjusted according to needs to meet the performance, size, and shape requirements of different customers.

Alu-Zn Alloy Wire

aluminium zinc coating wire

Weight formula

Weight (kg) = [π × (diameter/2)² × length] × density ÷ 1000

Reference value of zinc-aluminum alloy density (ρ)

- Zn-5%Al (Galfan): density 6.8~7.0g/cm³.

- Zn-10%Al: density 6.6~6.9 g/cm³.

- Zn-22%Al (Galvalume): density 6.4~6.7g/cm³.

Applications

Construction industry

- Manufacturing of doors, windows, curtain walls, and roof components, reinforcement bars, metal strips for waterproofing coils, prestressed steel wire, wire rope, and steel strands.

Automobile and aviation

- Manufacturing of engine parts, chassis fasteners such as bolts and nuts, and suspension system wire, suitable for vehicles in high humidity or coastal areas.

- Manufacturing of aircraft engines and parts to meet the stringent requirements of aerospace for materials.

Transportation and bridges

- Key load-bearing components such as main cables and hangers of cable-stayed bridges and suspension bridges have better salt spray corrosion resistance than ordinary galvanized steel wire.

- Highway guardrail steel wire, railway fence net, resistance to automobile exhaust, rain, snow, and industrial dust, bolts and rivets for tunnels, subway tracks, and underground pipelines.

steel cable manufacturer

Chicken Fence

Gabion Wall

Ocean and ships

- Ship anchor chains, mooring wires, and deck fence cables. Binding wires and protective nets for offshore steel structures. Port crane wire ropes, dock anti-collision facility connectors, and underwater cable armored wire.

Industrial and daily necessities

- Computer casings, mobile phone casings, electronic equipment radiators and other components, weaving industrial filter grills, steel balls, manufacturing spring steel wire, hinge steel wire, used for furniture, doors and windows, and other daily hardware.

- Manufacturing steel belts and baling wires for heavy cargo bundling, replacing traditional galvanized steel belts.

- Greenhouse cables, planting rack wires, fishing nets, and aquaculture cage frame wires.

Energy and electricity

- Photovoltaic brackets and other components, wind turbine tower fastening wires, connecting bolts, transmission line guy wires, tower binding wires. Grounding wires and lightning strips, their conductivity and corrosion resistance, improve the reliability of the grounding system.

Medical equipment

- Surgical instrument springs, orthopedic implant connectors, food packaging machinery chains, and conveyor belt wires meet health and safety requirements.

Hay baling wire tying

Farm fence barbed wire fencing

Binding Wire in Construction

Production Process

Factory aluminum zinc wire production video

Production steps

1. Alloy Preparation

Firstly, aluminum ingots are placed in the crucible. Next, after the aluminum ingot is melted, add the zinc ingot in a certain proportion. Wait until both are all melted and then stir well. Finally, add a degassing agent for degassing refining for 5~10 minutes.

2. Coarse Embryo Preparation

The coarse embryo preparation is carried out by a shock chain type horizontal continuous casting equipment, which uses the tension and relaxation of the drive chain to realize the stop-pull mechanism and finally the horizontal continuous casting. The process is to add the alloy liquid to the continuous casting furnace and maintain it at the specified level and temperature. Then the ingot drawing system is activated to draw out the rough embryo. After passing the inspection, the rough ingot will go to the next process.

3. Drawing Process

Drawing is the final process of transforming zinc aluminum alloy into a specific size. First of all, the coarse embryo is added to the holding furnace for preheating. After a period of holding, they are drawn. Depending on the wire diameter, the number of pulls varies. For example, a wire with a finer wire diameter will be drawn more often.

Alloy steel wire rod

Zinc aluminum alloy wire production line

zinc alloy coating

Quality inspection and packaging

1. Quality inspection

- Composition analysis: Use a spectrometer to detect the content of zinc, aluminum and other elements to ensure that they meet the standards (such as Zn-5%Al or Zn-10%Al).

- Mechanical properties: Test tensile strength, elongation, etc. to ensure that the wire meets the requirements of use.

- Surface quality: Check for defects such as cracks, burrs, oxide scale, etc. to ensure smoothness and uniformity.

- Diameter tolerance: Use a micrometer or laser diameter gauge to ensure that the wire diameter meets the specifications (such as ±0.02mm).

- Corrosion resistance: The Salt spray test evaluates the corrosion resistance of the coating or alloy.

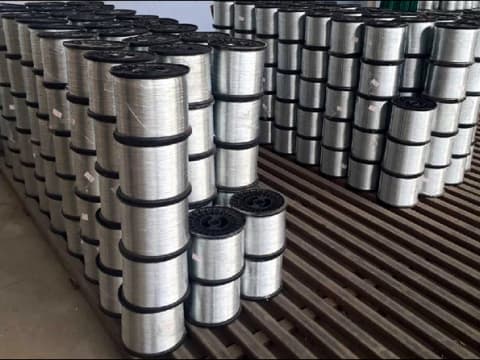

2. Packaging method

- Winding method: Use an I-shaped wheel or a spool to wind neatly to avoid twisting and deformation.

- Rust prevention: Apply anti-rust oil or vacuum packaging to prevent oxidation.

- Outer packaging: The inner layer is wrapped with moisture-proof paper or PE film, and the outer layer is reinforced with wooden boxes, iron barrels, or woven bags, and labels are affixed to indicate material, specifications, batches, and other information.

1.5mm zinc aluminum wire roll

Standard package

22 gauge zinc aluminum alloy spool wire

After passing the quality inspection, it can be put into storage or delivered to customers to ensure product reliability and durability.

Precautions When Transporting and Storing Zinc Aluminum Alloy Wire

The correct way of transportation will not damage the wire. Proper storage methods can make the wire last longer. Next, Wanzhi Steel will show you how to transport and store metal wire.

1. Before shipping, make sure that the wire is packed tightly to prevent it from being damaged due to bumping in transit.

2. It is forbidden to ship steel wire in packages and conveyances with acids, alkalis, salts, etc. that corrode zinc.

3. For storage, it should be placed in a dry, ventilated warehouse free of corrosive substances.

4. When stored outdoors, do not let it get wet by rain.

5. Avoid heavy pressure, store flat or vertically to prevent deformation of the wire or surface damage.

6. Regular inspection. During long-term storage, check the surface condition regularly and re-treat with rust prevention if necessary.

aluminium alloy welding wire

16 gauge alloy wire coil

Zinc Wires in Stock

Export Case

322 tons of Galfan Wire shipped to Kyrgyzstan

322 tons of Galfan Wire shipped to Kyrgyzstan.

Where to buy Zinc Aluminum Wire – Wanzhi Steel

Wanzhi Steel is an experienced steel wire manufacturer. The steel wire we provide is manufactured with advanced equipment and instruments to ensure that the composition of zinc-aluminum alloy meets the requirements. The aluminum alloy wire we produce has a bright surface without impurities and is durable. In addition, we have a professional team that can provide practical suggestions for your project.

If you want to know about zinc-aluminum alloy wire, welcome to contact Wanzhi Steel!

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001 certified steel factory located in Hebei, China. We’ve been focusing on the production of Baling Wire, aluminum wire, Q195/Q235 low-carbon wire, stainless steel wire, galvanized wire, and Galfan wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and excellent services, its products have been exported to over 120 countries worldwide.

Leave Us A Message