Wire Mesh For Concrete Slab

Wire Mesh For Concrete Slab is made of low carbon steel wire, also known as welded wire mesh (WWF) or steel mesh, it consists of cross-welded steel wires and has good toughness and tensile strength. It is used in conjunction with concrete to prevent masonry cracking and is used in construction fields such as roads and buildings.

– Wire Gauge: BWG12-BWG24

– Length: 5m,10m,25m,30metc

– Height: 0.8 m- 2.4 m

– Transportation: By air, by sea

– MOQ: 3 tons

– Use: Building materials

| Chat Online | Send Email |

Wire Mesh For Concrete Slab Specification

| Item | Wire Mesh For Concrete Slab(Plain Weave Welded Concrete Reinforcing Mesh) |

| Material | Q195, Q235 Low-Carbon Iron Wire, Galvan Iron Wire, Black Wire Mesh, and others |

| Type | Welded Mesh |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Surface treatment | electro galvanized, hot dipped galvanzied, powder coated, Epoxy coated |

| Aperture | 60*150mm, 50*75mm, 50*50mm, 50*100mm, 100*200mm, etc |

| Payment Term | FOB/CFR/CIF |

| Payment method | T/T 30% Prepayment |

Types of wire mesh for concrete slabs

1. Welded wire mesh (WWM): The most common type, welded from cold-drawn steel wire. Wire gauge and mesh size can be customized.

2. Expanded metal mesh: Made from a single piece of steel cut and stretched into a diamond pattern. Has good strength and drainage properties.

3. Fiber mesh: Made from small randomly oriented fibers mixed into concrete. Has some crack resistance, but not as strong as wire mesh.

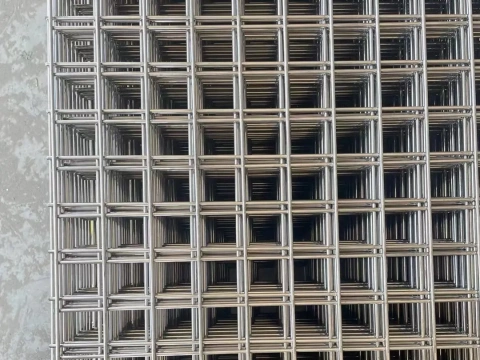

Concrete mesh-smooth round bar welding

reinforced concrete slab china factory

Welded concrete mesh

Benefits of Using Wire Mesh in Concrete Slabs

1. Added Strength: This heavy-duty 2×4 galvanized welded wire mesh panel is very durable and in addition to being resistant to cracking can be used for wildfowl coops and large dog kennels.

2. Customizable aperture: A variety of opening options are available, including 60x150mm, 50x75mm, 50x50mm, 50x100mm, and 100x200mm.

3. Multiple Finishes: Choose from galvanized, PVC coated, powder coated, and more.

4. Various sizes: Available in lengths of 5m-30m and heights of 0.8-2.4m, customizable.

5. Cost-effective: Compared with other reinforcement methods such as steel bars, wire mesh is relatively cheap and easy to install. It is a cheap alternative to steel mesh.

6. Conforms to international standards: Produced in accordance with ISO 9001:2015 standards, conforming to international quality standards, safe and reliable.

Wanzhi Wire mesh for concrete slab Cases

623tons Welded mesh shipped to Moldova

Wire mesh for concrete slab price

According to different applications, different steel diameters, corresponding to different prices, the following as a reference, can ask Wanzhi Steel for a quotation.

For example:

1. Mesh size: 100mm×100mm, 150mm×150mm, 200×200mm. Wire diameter: 5-10mm, mesh panel 2.2×5.8, 2.3mx5.9m,2.4mx6.0m. The price starts from $0.6/meter. Our price range at this stage is $10-45/pc.

2. 6 Gauge Concrete Wire Mesh is now available from $630/ton.

3. By the square, 0.25-0.38” wire diameter, 3 x 3cm mesh, lengths 5-30 meters, etc., prices start at $2/square.

Spider Chairs Reinforcing Bar and Mesh in Suspended Slabs are available for sale.

Can you use wire mesh in the concrete slab?

The answer is split into situations, depending on what you are using it for.

1. Simple projects

when you are using it on the ground that does not need to carry a lot of loads, such as a one-story building, a regular park, a simple shelter, then wire mesh can be used, and in some cases, it is not even needed.

2. Lightweight, Minor Works

In smaller projects, usually with low structural requirements, such as residential driveways, sidewalks, or decks, wire mesh can provide adequate support. It can be used to reinforce concrete slabs and walls. Typically, 10-gauge wire mesh is used, which holds concrete together during temperature changes. 6-gauge wire mesh is also commonly used, but this gauge is sometimes overkill.

3. Large, complex projects

wire mesh is necessary when you are working on bridges, airport runways, floor slabs, or more complex projects. it helps prevent the sections of a concrete slab from separating horizontally or vertically after cracking, but does not improve tensile strength or stiffness. Therefore it is also necessary to use reinforcing steel to improve stiffness and strength, but to avoid overloading the structure into yielding.

reinforcement mesh for garage

concrete reinforcing mesh

Where should wire mesh be placed in concrete?

In the case of 4 – 6 inch thick residential slabs, the grid should be placed at mid-depth.

It is difficult to place the grid in the upper third if you want to avoid the saw kerf and get a small amount of coverage. It is recommended that it be anchored in the center of the floor slab.

The grid must be at least 5 cm above the compacted substrate and about 4 cm below the top of the slab.

The most common methods of laying WWR are (1) Chair WWR, (1) Pouring concrete in two layers and placing WWR in the first layer.

How to lay wire mesh for concrete?

Tools: Cutting tools for the steel and the wire, bar chairs, power lead, safety gear, measuring tape, and joining wire.

1. Excavate the ground, measure the length of the trench, level each flat surface, and lay bar chairs at about 1 meter intervals, symmetrically placed along the trench.

2. Cut the wire mesh to be cut, and tie the overlapping mesh with the joining wire first, covering a length of at least 500mm.

3. Then Pour concrete.

mesh cement

wire mesh for concrete

concrete mesh

FAQs

1. Should I put wire mesh in the concrete slab?

Larger projects in general, such as utility buildings, parking lots, viaducts, and airports definitely require the placement of reinforcing wire mesh in concrete slabs. Concrete slabs on their own are usually less than ideal, so the placement of wire mesh not only distributes the load weight evenly, holds the material together, provides support and extra strength in addition to helping to minimize cracking and settlement of the concrete slab. It is an essential step in construction work.

2. What gauge wire mesh for concrete slab?

The gauge of the wire mesh usually depends on the actual situation. Standard construction wire mesh applications are residential and light commercial concrete reinforcement.

For light loads, 10 gauge wire mesh is sufficient; for higher loads you may need 8-gauge (D2.1), 6-gauge (D2.9), or 5-gauge.

3. What size is steel mesh for a concrete slab?

Standard reinforcing mesh panel size is 6.0 m x 2.4 m (holes: 150 mm x 150 mm), 1/8 inch (4 mm) thick

Trench mesh products are available in lengths of 6.0 meters and standard widths of 200-400 mm.

Galvanized welded mesh shipped to India

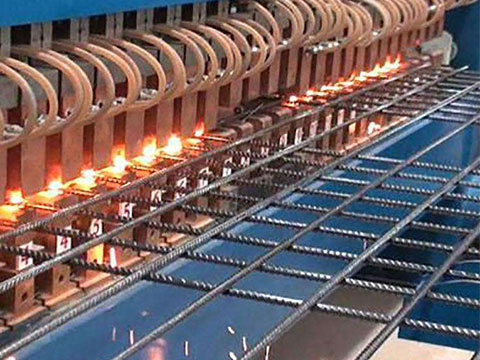

Galvanized Concrete Mesh Production Line

Hot-dip Galvanized Welded Mesh Panel

4. When to use wire mesh in concrete?

When your project is slightly more complex, or your building requires higher load bearing, simple concrete is not enough for the project, especially when the concrete shrinks and cracks as it dries. This is when the slab needs to be reinforced by embedding wire mesh or fiber mesh etc. in the wet soil. Secondly, proper soil compaction can also alleviate cracking due to uneven settlement.

5. Does wire mesh keep concrete from cracking?

No, it will not, it acts as a reinforcement but does not stop the concrete from cracking. Reinforcement slows the expansion of concrete cracks. Concrete and steel have different thermal expansions and they elongate differently under stress. The strength of the two is also different; concrete is good at resisting stress, but poor at resisting tension. Concrete will crack first from thermal or mechanical stress. After it cracks, then the steel reinforcement will engage. Think of the bottom of a concrete beam bending. The steel holds everything together like a bungee cord. Therefore, for the wire mesh, its bond with the concrete will not be very bad, so it is very important in construction.

6. What is the wire mesh in concrete called?

Welded or reinforcing mesh, available in rolls or sheets, usually galvanized. Reinforcing steel contributes to axial strain and cracking throughout the floor slab. Increases the tensile strength of the mesh.

Quality Inspection

Galvanized mesh after welding

Welded concrete mesh

Concrete Slab Wire Mesh For Sale – Wanzhi Steel

Wanzhi Steel Structure, as a high-quality supplier of concrete mesh panel, Welded Mesh panel, Reinforcing Steel mesh, accepts size customization, non-standard production and third-party quality inspection. If you have special requirements, you can contact us at any time!

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of high-quality rebar coil, ribbed bar, welded rebar mesh sheet, Galvanized Concrete Mesh, Galvanized Steel Stucco Netting, and Diamond Mesh Lath for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message