Steel Reinforcement Bar

Diameter: 4-40 mm

Delivery Time: 10-18 Days

Transportation: By land, by sea

Steel Reinforcement Bar

Steel reinforcement bar, also known as threaded steel, is a long, ribbed carbon structural steel or low-alloy steel strip primarily used to enhance the tensile strength of concrete structures. Its grade is named based on its yield strength (e.g., HRB400), and it boasts high strength, excellent adhesion, and seismic resistance. As the backbone of modern architecture, it is widely used in foundations and main load-bearing components of civil engineering projects such as buildings, bridges, and roads, making it one of the most essential materials in engineering construction. Wanzhi Steel stocks rebar in various materials and diameters, available in straight bars or coils. A variety of grades are available, including A615, Gr40, Gr60, HRB335, HRB400, and HRB500. If you are interested, please feel free to contact us.

Steel Reinforcing Bars

Deformed Steel Reinforcing Bar

Steel Reinforcement Bars Specification

| Item | Steel Rebar |

| Place of Origin | Shandong, China |

| Model | 5#, 6.5#, 7#, 9#, 10#, 12#, 14#, 16#, 18#, 20#, 22#, 24#, 25#, 28#, 30#, 32#, 34#, 36#, 38#, 40# |

| Types | Plain round bar, deformed bar |

| Stock Length | 6 m, 9 m, 12 m |

| Grade | HPB300, HRB 335/HRB400/500/600, HRB400E/HRB500E, HRB600E, BS4449 460B/500B |

| Standard | ASTM/GB/JIS/DIN/AISI/BS |

| Shape | Straight-bar, Threaded coil, Rebar Coil |

| Usage | Building Construction Material |

| Sample | Free and available |

| MOQ | 5 Tons |

| Package | Long in bundles (10 ~ 40 mm) or in coils (6 ~ 16 mm) |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Payment Terms | TT 30% Advance + 70% Balance |

What Is Rebar?

Rebar, short for reinforcing bar, is a hot-rolled round steel bar with a circular cross-section. It is formed by hot rolling and then naturally cooled. It is primarily used in concrete or asphalt pouring. Carbon steel is the most common material, but stainless steel and galvanized rebar are also available, with a variety of surface finishes. Threaded rebar, also known as ribbed rebar, features ribs, lugs, or projections on its surface. According to the supply form, there are coil rebars and straight reinforcement steel.

Hot dip galvanized rebar

Deformed Bar Coils

Features of Reinforcing Steel Bar

- High strength: HRB500 has a tensile strength of 630MPa, which is more than 100 times that of concrete.

- Ductility: Elongation ≥16% (HRB400), can absorb energy without breaking during earthquakes.

- Hot rolling process: Grain refinement improves strength (grain size ≥8).

- Adhesion: Crescent rib design increases the bonding strength by 40% compared with round steel bars.

- Alloy composition: C content 0.17-0.25%, Mn content 1.20-1.60%.

- Durability: high toughness, good corrosion resistance, and fire resistance.

- Various specifications: a variety of sizes, surface treatments, and grades are available.

- Wide uses: cold-rolled steel coils can be used for continuous reinforcement (hoops, distribution bars), hot-rolled steel bars (straight bars), main force bars (beam, column longitudinal bars).

Deformed Steel Rebar in Bundles

stainless steel rebar

Uses of Steel Reinforcement Bar

Reinforcing steel bar is a kind of building material that can increase the strength of the structure. Generally, these bars are welded or bound together during use. You can find rebars in all kinds of construction structures, such as bridges, highways, culverts, tunnels, beams, columns, walls, etc.

Uses of different diameters

- 8 mm /10 mm: This thin mild steel rebar is ideal for projects like swimming pools, driveways, and patios, to provide the structure with shape and strength.

- 15 mm: Slightly thicker. It is perfect for use on highways, bridges, columns, roof slabs, or floor slabs.

- 20 mm: Widely used in foundations, retaining walls, or highways, as well as structural support, like bridges.

- 25 mm: It is suitable for medium to heavy building structures, such as columns, beams, and retaining walls; when the steel rebar is thicker than 25 mm, an 18 gauge rebar binding wire is required.

- 30 mm: Thicker and more durable, which is an ideal option as the structural support of medium or heavy construction projects, like warehouses, beams, columns, etc.

- 35 mm: It is thick and strong, which is well suited for load-bearing structures.

- 45 mm: This rebar size is designed for large and tall buildings, bridges, and other civil works.

Bridge

Foundation

Tunnel wall and pavement reinforcement

Types of Steel Reinforcement Bars

Classification by production process

- HRB: Hot-rolled rebar steel, high temperature rolling, moderate strength, most commonly used.

- CRB: Cold-rolled steel rebar, cold work hardening, high strength but poor ductility, mostly used for small components.

- HTB: Heat-treated reinforcing bar, through quenching + tempering to improve strength, used for prestressed concrete.

Classification by surface

- PB: Plain round reinforcing steel rebar, smooth and flat surface, weaker bonding.

- RB: Ribbed rebar, with horizontal/vertical ribs on the surface, enhanced bonding. Therefore, it can withstand greater external forces.

- DB: Deformed Bar, spiral ribs, stronger bonding.

Plain Round Bar

Ribbed Steel Bar

Classification by diameter

Steel rebar rods (diameter of 3~5 mm). Fine metal rebar (diameter of 6~10 mm). Thick concrete rebar (> 22 mm).

Classification by material

- Carbon steel rebar: black steel rebar, the most commonly used material. Because of its carbon black color, it is also called “black steel bar”. It has certain toughness and strength, can effectively resist external forces, and is not easy to break, but it is easy to corrode. High humidity environment should be avoided. It can be galvanized for corrosion prevention.

- Stainless steel rebar: the most corrosion-resistant and durable steel bar with the highest price. It can extend the service life of concrete structures under corrosive conditions, such as in areas where deicing salt is widely used or in marine environments. It can maintain strength, toughness, and ductility at extremely low or high temperatures.

Classification by coating

- Hot dipped galvanized rebar: apply zinc protective layer to the steel bar surface by continuous hot-dip galvanizing, which can effectively prevent corrosion when the steel bar is embedded in concrete. Its bonding strength is much higher than that of black steel or epoxy-coated steel bars. The price is also more affordable than stainless steel bars.

- Eepoxy coated rebar: epoxy resin powder is sprayed on its surface using electrostatic spraying technology, and the coating thickness is 0.15~0.30mm. It improves the corrosion resistance of steel bars, effectively prevents steel bars from rusting, and improves the durability of concrete structures, but the bonding strength with concrete is poor, and it is suitable for industrial and civil buildings in humid or corrosive environments.

Epoxy Coated Rebars

Steel Reinforcement Mesh

Common Series

HPB Series (Hot-Rolled Plain Bar)

- HPB300: Yield strength 300 MPa, smooth surface (no ribs), weak bonding with concrete.

HRB Series (Hot-Rolled Ribbed Bar)

- HRB335: Yield strength 335MPa, old brand, gradually eliminated. Used in low-rise buildings.

- HRB400: The most commonly used brand at present, yield strength of 400MPa, used in high-rise buildings, bridges, wide range of sizes.

- HRB500: Yield strength 500MPa, high strength, saving steel, thicker diameter, used for large-span structures and heavy-load projects.

- HRB600: Yield strength 600MPa, ultra-high strength, used for special projects.

Earthquake-resistant steel bars

- HRB400E/500E/600E: Earthquake-resistant steel bars are used in high-intensity earthquake zones.

Seismic steel bars, based on ordinary HRB steel bars, improve ductility and seismic resistance, suitable for buildings in high-intensity earthquake zones such as schools and hospitals.

British Standard Steel Bar

- BS4449 460B/500B: British standard steel bar, similar to HRB400/500.

BS4449 stands for British steel bar standard. 460B/500B: Yield strength 460 MPa/500 MPa. B: Weldable steel bar (different from “A” type non-weldable steel bar).

Other common series

- Grade 60: ASTM A615 American standard, yield strength 420 MPa, similar to Chinese grade HRB400.

- SD390: JIS G3112 (Japanese standard), yield strength 390 MPa, similar to Chinese grade HRB400.

- B500B: EN 10080 (European standard), yield strength 500 MPa, similar to Chinese grade HRB500.

Q235 Steel Rebar ASTM GR60,BS GR460,SS400

Steel Reinforcement Bars

Rebar Sizes and Grades

Sizes: Rebar comes in a variety of diameters, typically from #3 (3/8 inch) to #18 (2.25 inches). Sizes are indicated by a number corresponding to one-eighth of an inch of its diameter.

Grades: Rebar is graded based on its yield strength in psi or MPa. Common grades include:

- Grade 40: has a yield strength of 40,000 psi.

- Grade 60: has a yield strength of 60,000 psi (most commonly used).

- Grade 75: has a yield strength of 75,000 psi.

- Grade 80: has a yield strength of 80,000 psi.

This article comprehensively talks about Steel Rebar Sizes, Grades & Codes.

Hot Rolled Hrb400 Hrb500 coiled steel rebar

Ribbed Reinforcement Bars

How To Identify Steel Bars?

The rebar is marked with symbols and numbers to indicate:

- Manufacturer Plant: Identifies the manufacturing plant.

- Rebar Size: Indicates the diameter.

- Grade: Specifies the yield strength (e.g., 60 for Grade 60).

- Type: Identifies the material (e.g., “S” for carbon steel, “W” for low alloy steel or weldable steel such as Grade 60W).

- C: Cold-finished steel (e.g., B500C).

The meaning of each character in HRB500E/HRB400

- H: Hot Rolled, indicates hot rolling process, which means that the steel bar is formed by high-temperature rolling.

- R: Ribbed, indicates ribbed, with regular ribs on the surface of the steel bar to enhance the bond with concrete.

- B: Bars is the English abbreviation for steel bar, indicating that the product is a steel bar.

- 500/400: The standard value of yield strength is 500MPa/400MPa, which belongs to Grade 4 steel bar or high-strength steel bar.

- E: Indicates earthquake resistance. None = ordinary steel bars, E = seismic steel bars (must meet the yield strength ratio ≤ 1.25, maximum force total elongation ≥ 9%).

Surface Shape Identification:

- Crescent rib: HRB series standard pattern (increases bonding strength by 30%).

- Cross rib: commonly used in Europe (such as B500B).

Color Marking (Used By Some Manufacturers):

- Blue end: earthquake-resistant steel bar.

- Yellow end: high-strength steel bar (HRB500).

Hot Rolled Deformed Bars

Concrete Reinforcing Bar

Weight calculation formula of rebar

Weight (kg)= Diameter (mm) × Diameter (mm) ×0.00617 × Steel bar length (m).

For example, if the ribbed steel reinforcing bar is 16 mm in diameter and 9 m in length, then the weight is about 14.22 kg (16*16*0.00617*9). If you order 3,000 pieces, the total weight is about 43 tons. Through the formula here, you can roughly know the weight.

Wanzhi Steel Steel Rebar Case

rebars shipped to Saudi Arabia

Why Use Steel Rebars in Construction?

Because rebar can reinforce concrete structures. Although concrete has high compressive strength, it has low tensile strength, while rebar has high tensile strength, making it very suitable for concrete slabs, walls, columns, beams, foundations, etc.

Why galvanized?

- Rusting of steel reinforcement is the most important factor affecting the durability of concrete structures. Rusting will cause volume expansion, which will dislodge the protective layer of concrete and even produce longitudinal cracks, further affecting the normal use of the overall structure.

- Rusting of reinforcing bars also destroys the bond between the bars and the concrete, reducing the bearing capacity of the concrete.

Therefore, galvanizing or epoxy coating is an effective way to prevent further corrosion of steel bars.

Steel Rebar Production Process

Generally, there are four processes: rust removal, straightening, cutting, and forming.

Hot Rolled 10/12/16mm alloy Rod coil rebar

Deformed Bars

(1) Clean the adhered oil, soil, and rust, and the rust can be removed through the cold drawing process.

(2) Straighten the steel bars mechanically or manually. The straightened steel bars shall not have local bending, dead bends, or small waves. Besides, the surface scars shall not reduce the cross-section of the steel bars by 5%.

(3) Cut the steel bars based on the number, diameter, length, and quantity of the steel bars. As a rule, cut the long material before cutting the short material to minimize the short ends to save materials.

(4) Calculate the blanking length and size of the steel bar according to the drawings. Also, the end of the stirrup also needs to meet the requirements of the design drawings. Through a series of steps, including cross-hatching, steel rods are shaped into bars.

Get Wholesale Reinforcing Bar Price

The FOB price of deformed bars starts from USD 400. It differs with many factors, such as the material, steel grades, finishes, sizes, etc. Wanzhi Steel is a wholesale supplier of steel products in China. Therefore, we will offer you a fair price.

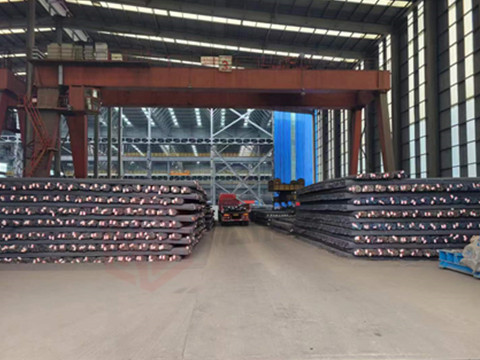

Reinforcing Bars at Factory

Warehouse

Concrete Rebar Manufacturer -Wanzhi Steel

Build stronger and safer with premium steel reinforcement bars. Whether for seismic applications or standard construction, our products deliver consistent quality and reliability. Wanzhi Steel stocks major grades like HRB400, HRB500, and ASTM A615. Get a competitive project quote within 24 hours. Submit your inquiry now and strengthen your supply chain.

Why Choose Us?

✅ Advanced Equipment: Fully automatic production line to ensure high precision and consistency.

✅ Strict Quality Control: ISO 9001 certified and strict testing standards.

✅ Rich Material Selection: Carbon steel, galvanized steel, stainless steel, and other materials are available.

✅ Customized Service: Special size, length, surface treatment service, and welding are supported.

✅ Fast Delivery: With a large inventory and 1000 square meters of factory, bulk orders can be met.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized concrete mesh, steel wire rod, construction tying wire, low carbon iron wire, Steel Reinforcement Mesh, and annealed wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, our products have been exported to more than 120 countries around the world.

Leave Us A Message