Perforated Steel Mesh

Thickness: 0.2 mm – 10 mm

Width × Length: ≤ 1.5 m × 5 m

Hole type: round, square, hexagonal, slotted hole, pentagram, rhombus, etc.

Perforated Steel Mesh

Perforated steel mesh is ideal for many architectural and decorative metal applications. Commonly used are round holes, square holes, cross holes, etc. Different shapes give it a unique aesthetic and a wide range of uses. Wanzhi Steel has a large number of perforated sheets, coils, and strips in regular thicknesses, including galvanized sheets, stainless steel sheets, GL, and aluminum sheets. Lengths, widths, and thicknesses can all be customized, with factory direct prices. Welcome to contact us to learn more.

Perforated Steel Mesh

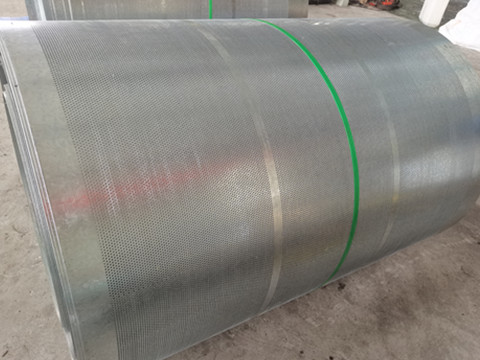

Perforated Metal Roll

Perforated Steel Mesh Specification

| Item | Perforated steel mesh |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Cold Rolled |

| Shape | Flat Steel Plate |

| Material Grade | DX51D/DX52D/SGCC/CGCC/TS350GD/Q195/Q235, 200/300/400 series SS, 1100/1050/2024/3003/5052/5083/5086/6061/7075 Aluminum |

| Surface treatment | Hot dip Galvanized, hot dip galvalume, pattern printed, powder coating, tin coated |

| Coating thickness | Galvanized steel: Z30-Z275, Galvalume steel: AZ30-AZ150 |

| Benifits | Breathable and light-permeable, durable and lightweight, anti-corrosion, and long service life |

| Color | Silver, can be customized according to RAL color card |

| Packing | Standard export packaging |

| Processing Service | Bending, Welding, Cutting, Punching, Slitting, Perforating |

| Usage | Filters, decoration |

| Delivery Time | 15-28 days |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Available |

| Price Item | FOB, CIF, EXW, etc |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

| Transportation | By sea, by land |

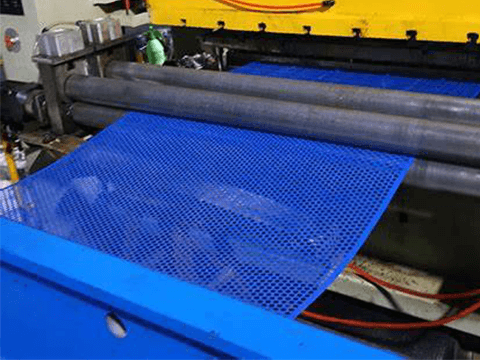

Production Video

This is a video of the production of aluminum perforated coils.

- Material like perforated coils of galvanized steel, stainless steel, zinc-aluminum coated steel, and tin-plated steel can also be produced.

- Colors like red, blue, white, black, etc., can be specified.

What Is Perforated Metal Screen?

Steel perforated metal is a mesh material with regular holes formed on metal sheets such as stainless steel, aluminum, carbon steel, galvanized steel, etc., by stamping, laser cutting, or CNC drilling. Its hole shapes are various (round holes, square holes, hexagonal holes, etc.), and it has functions such as ventilation and light transmission, filtering and shielding, and decoration and beautification.

Stainless Steel Perforated Sheet Hexagonal hole

Used in building curtain walls, mechanical protection, agriculture, home furnishing, noise reduction, and other fields. It has the characteristics of high strength, corrosion resistance, and easy processing. The aperture, arrangement method, and plate thickness can be highly customized.

Types of Perforated Steel Mesh

Perforated metal sheets are classified into many types according to their hole diameter, hole spacing, plate thickness, plate material and x-shape, including but not limited to the following: pattern perforated Wire Mesh, formed perforated wire mesh, extra-thick perforated wire mesh, extra thin perforated wire mesh, micro-perforated wire mesh, wire cut perforated wire mesh, laser perforated wire mesh, etc.

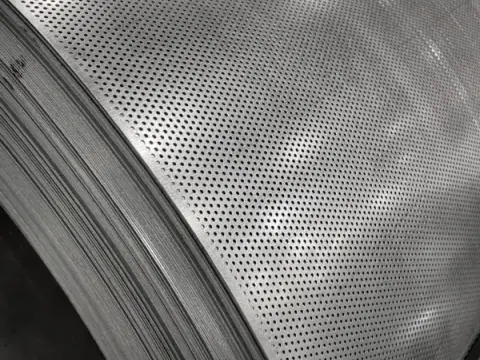

Perforated Stainless Steel sheet coil

Perforated mesh hole type

Advantages of Perforated Metal Mesh

1. Aesthetically Pleasing

Perforated mesh panels are very attractive. This is because this metal has almost endless options in terms of hole shapes, sizes, geometric patterns, and surface finishes. When it is used in buildings, it not only adds visual interest but also maintains a degree of privacy.

2. High Strength and Durable

The perforated metal mesh sheet has high strength. It has the ability to control or balance pressure. This means that perforated wire mesh has a structural strength that many other materials do not have. In addition, it is able to withstand a variety of weather conditions. Even when it is used in harsh environments, it still performs excellently.

3. Energy Efficient

Perforated steel mesh sheets are designed to provide light and ventilation. It allows natural light to penetrate into the room without the need for extensive interior lighting during the day. This can save a lot of electricity consumption.

4. Good Sound Absorption Effect

Perforated mesh is installed on the wall or roof of a building, leaving a certain gap. Sound waves enter the gap through the holes of the perforated mesh, and the holes of the perforated mesh can absorb the sound. When the sound enters the gap between the perforated mesh and the wall, it will be reflected or refracted, thus achieving the effect of noise reduction.

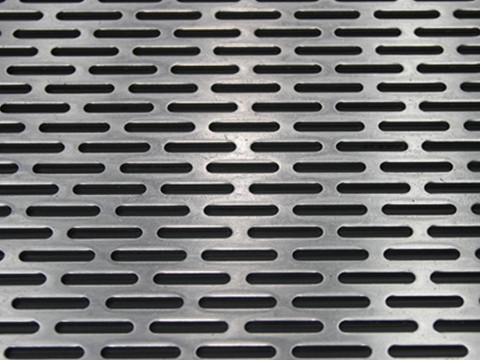

Slotted Perforated Mesh

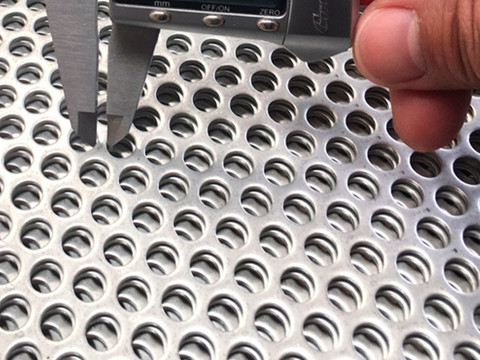

Quality Inspection

Aperture measurement

Uses of Perforated Steel Mesh

Application of round hole perforated mesh

- Architecture: exterior wall decoration, sunshade, canopy, and other parts, with both ventilation and aesthetics. Indoor partitions, ceilings. Sound barrier materials to reduce noise transmission.

- Environmental protection and filtration: air purification equipment. Waste incinerator exhaust system, intercepting fly ash and particulate matter.

- Food and medicine: drying equipment to prevent food particles from clogging. Mechanical equipment screening and filter mesh.

- Daily and industrial: kitchen utensils (fruit baskets, food covers, fruit plates), shelf nets, decorative booths. Speaker production uses permeability to transmit sound.

Application of elliptical hole perforated mesh

- Ventilation and filtration: ventilation ducts, vents. Filters, filter screens, remove impurities and suspended matter in water.

- Industrial equipment: filter components of chemical machinery, pharmaceutical equipment, food and beverage machinery.

Perforated stair treads

Modeling perforated galvanized sheet

Perforated mesh pipe

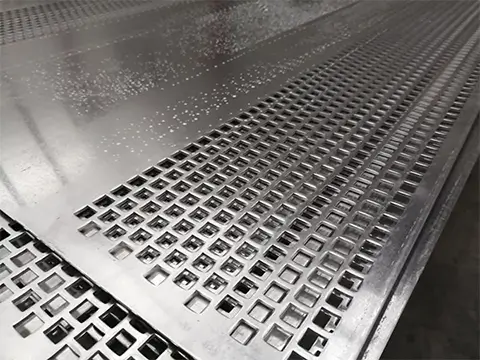

Application of square hole perforated mesh

- Screening and filtration: screening of gravel, filtering of liquids and gases in industry and construction. Safety and protective mechanical covers.

- Daily necessities: kitchen tools such as colanders and strainers.

Application of oblong hole (rectangular) perforated mesh

- Vibrating screen and filtration: solid screening, such as staggered oblong holes for fine screening. Filter components for chemical machinery, pharmaceutical equipment, food and beverage machinery.

- Industrial equipment: Filtration and protection of cigarette machinery, harvesters, dry cleaning machines, and ironing tables.

Application of hexagonal hole perforated mesh

- Architecture and decoration: environmental noise control barriers in transportation and municipal facilities. Architectural decorative perforated plates and ceilings.

- Industrial protection: mechanical equipment protective covers, speaker mesh covers. Filter equipment such as mine screens and I-shaped screens.

Ceilings of Buildings

Perforated wall panels

Application of other hole types (such as triangular holes, fish scale holes, etc.)

- Filtration: Filtration and protection of chemical machinery, pharmaceutical equipment, food and beverage machinery.

- Textile: fine parts in the fields of handicraft production, papermaking, hydraulic accessories, etc.

- Decoration: public facilities such as park punching trash cans and street lamp decorations. Anti-skid plates in aisles and workshops in public places to reduce the risk of slippery.

What Materials Are Available in Perforated Mesh?

1. Cold rolled steel

Cold rolled carbon steel sheet is a kind of passable plate rolled at recrystallization temperature data with the following. Its thickness is 0.2-4mm, width is 600-2000mm, length is 1200-6000mm. The cold rolling process has higher precision, higher finish and very smooth surface.

2. Galvanized/Galvalume perforated sheet

The surface of galvanized steel sheet is coated with a layer of metal zinc, and the surface of galvanized steel sheet is coated with zinc-aluminum alloy, both of which are used to prevent rust. The latter has a longer life than the former. In addition, this type of material is more economical than stainless steel and can adapt to various corrosive environments.

Perforated galvanized sheet

perforated stainless steel mesh

3. Stainless steel perforated mesh sheet

Stainless steel sheet is often used in the perforated industry in wet or particularly corrosive locations. Perforated stainless mesh has greater corrosion and wear resistance than galvanized sheets, but is much more expensive than GI sheets.

4. Aluminum Sheet

Aluminum perforated panels are generally used in the building decoration design industry, such as in ceiling suspension systems. Moreover, aluminum panels are very light in weight, which can prevent the natural sagging caused by the relatively long time of the ceiling by effectively.

5. Tin Plate

Tin-plated perforated sheet has the characteristics of corrosion resistance, good conductivity, strong heat dissipation, easy welding, beautiful and durable, etc. It is suitable for electronic shielding, decoration and other fields. The surface is brighter and the corrosion resistance is weaker than that of galvanized sheet.

Perforated aluminum sheet

Galvalume perforated steel strip

Thick square hole perforated plate

Paint Types for Color-Coated Perforated Sheets

Colored perforated metal mesh can be achieved by painting. Wanzhi Steel commonly uses the following 4 types of paint.

- PE: Polyester, good adhesion, tightly bonded to the substrate. Good flexibility of the paint film, a variety of color options. Suitable for general environments, maintenance-free for 8-10 years.

- SMP: Silicon-modified polyester, good paint film hardness, wear resistance and heat resistance, fast curing, can resist erosion in the outdoor environment, anti-powdering paint film, good adhesion. Pollution resistance and weather resistance.

- HDP: High weather-resistant polyester, good color retention and UV resistance, maintain long-term bright colors, not easy to fade. Good outdoor durability, anti-powdering and molding performance.

- PVDF: Fluorocarbon, superior anti-powdering, acid and alkali resistance, corrosion resistance, wear resistance, UV resistance, suitable for extremely harsh environments, such as coastal areas, chemical plant rooms, etc. The paint film presents a metallic luster and has the longest life.

Red perforated metal sheet decorative

Blue perforated corrugated board supply

black perforated metal sheet

What is powder coated perforated metal sheet?

In addition to paint coloring, powder coloring can also be used. Powder coated perforated metal is a type of perforated metal that uses powder coating technology to give it a colored surface. Powder coating technology electrostatically sprays fine paint powders onto the metal and then cures at high temperatures to create a hard, durable colored surface.

The reason it is preferred over liquid paint is that it is a “dry” coloring method. The paint does not run or drip and is evenly applied around the holes. It can be thicker, more vivid, and provides better durability than liquid paint.

Difference between Galvanized perforated sheet & powder coated perforated sheet

The main difference between galvanized steel and powder coated steel is how they resist rusting. The former is silver-grey, while the latter can be achieved in a variety of colors. In comparison, galvanizing provides a more durable, longer life than powder coating. Galvanized steel has a protective layer of zinc, while powder coating provides a protective resin layer. Galvanized steel can go on to be powder coated or painted.

Perforated Metal Production

Perforated corrugated board

perforated aluminum screen

Production process

- Mold design: adjust the hole diameter and spacing as needed. So that CNC equipment can be used for punching.

- Punching: single punching (suitable for simple patterns), continuous punching (partial stacking processing), can process long holes. Multi-directional continuous punching, use small molds to process large holes.

- Forming: single forming, shallow stretching according to the shape of the mold. Continuous forming: a processing method that forms larger than the mold size. Array forming: processing multiple workpieces on a large plate.

- Subsequent processing: trimming, using a leveling machine to restore the deformed plate after punching to a flat state, and cleaning to remove lubricants.

- Reprocessing: cutting, labeling, packaging, degreasing, deburring, forming, annealing, painting, electroplating, welding, polishing, bending, rolling, etc., according to customer needs.

- Surface treatment: surface treatment is carried out through additional measures such as powder spraying, painting, electrogalvanizing, hot-dip galvanizing, and anodizing.

- Packaging: Perforated mesh belts, perforated mesh rolls, and perforated mesh plates are all packaged in standard export packaging.

Blue hexagon perforated metal

hexagonal perforated SS steel sheet

Blue Perforated Galvanized Mesh Roll

Why Buy Perforated Steel Mesh from Wanzhi Steel?

1. Passing Quality

Our products are tested by a strict inspection system from production to delivery to ensure quality. We will design and manufacture satisfactory products for you with advanced technology, and a professional team. Measure the zinc content of the coating, coating thickness, salt spray test, and tensile test. We also support visiting our factory.

2. Provide Perforated Mesh Solutions

Wanzhi Steel has more than ten years of experience in the industry. If you don’t know how to purchase perforated wire mesh for your project. Our technical team of industry consultants with years of experience can provide you with perforated mesh procurement advice and exclusive solutions.

3. Factory Wholesale Price

Wanzhi Steel has its own factory, which offers a competitive price in the global market. We strictly control all costs in production and do our best to benefit our customers. Besides, if you are ready to order in large quantities, we can also offer you a wholesale sales price.

Galvanized Steel Mesh For Sale

430 304ss Metal Mesh Sheet package

40 60 90 Salt Spray Tester

4. Perfect Service System

From pre-sales to in-sales to after-sales, Wanzhi Steel has a perfect service system. We have formed a team that can communicate with customers promptly and swiftly. In addition, our professional after-sales service team will serve you 24/7 and solve your related problems in time.

How to Order Perforated Mesh?

When ordering perforated steel mesh, we need to know the following information. This information can help us to quote you quickly.

1. Which material of perforated mesh do you need?

2. Please tell us the exact specifications you need, including size, thickness, hole size, and shape.

3. The spacing and configuration you need.

4. How much-perforated mesh do you need to order?

Package

The packaging methods of perforated sheets, perforated rolls and perforated coils are as follows

98 tons 304 perforated sheet to Latvia

Alu-Zinc Coated Steel Perforated Roll

PPGI Perforated Coil Packaging

Get perforated metal sheet price from Wanzhi Steel

Perforated steel mesh is an economical choice for your project and it is well worth the investment. Perforated metal sheet for sale near me – Wanzhi Steel. We offer a range of hole types, sizes, specifications, and material types. Such as hexagon perforated sheet, black perforated metal screen, perforated stainless steel mesh, as well as perforated stainless steel screen and round perforated metal sheet, You can customize it according to the actual needs of your project.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of MS Perforated Sheet, Galvanized expanded metal lath, Perforated SS Steel Mesh, Welded Wire Sheets, perforated aluminum sheets, Steel Grating Plate, and Diamond Mesh Lath for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message