Search Results for: binding wire

Anti-climb fences are specially designed fences or grilles, referring to fences that prevent people from climbing or are difficult to cross and serve to protect the perimeter. Its mesh holes are very small, eliminating hand and foot contact and thus preventing climbing. It usually consists of welded wire mesh, steel mesh panel, tightly woven mesh, or perforated mesh. This type of fence is typically used in locations that require a high level of security, such as prisons, military bases, sensitive facilities, etc. WANZHI STEEL specializes in the production of anti-climbing fences and climb-resistant fences, with layers of product quality tracking, welcome to Contact us.

residential anti climb fence

anti climb fence top

Ⅰ. What is anti climb fence?

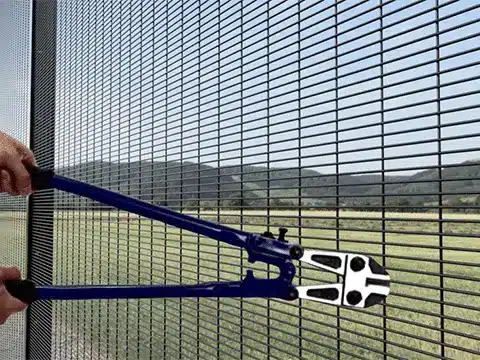

An anti-climbing fence, also known as a cut resistant fence, is a mesh that is uniquely welded to provide an aesthetically pleasing design with excellent security. It has a very small mesh opening or aperture of 0.5 inches, making it difficult for fingers, toes, and tool scissors to grab. In addition to this, its perfect visibility adds to its safety appeal.

| Item | Anti-climb fence |

| Height | 2.0-6.0m |

| Material | Galvanized Wire, PVC Coated Wire , Mild Steel Wire, Zinc Aluminum Alloy Wire |

| Wire Tensile Strength | 450-600 Mega Pascal (MPA) |

| Finishes | Powder Coated, Galvanized, PVC coated, Thermoplastic Coated |

| Estimated Lead Time | 15-20Days (determined by volume, does not include shipping) |

anti fence

anti climb railing

anti climb wall

Ⅱ. Advantages of anti-climb fence

-Anti-cutting and anti-scaling

-High security, if you add a barbed wire fence or razor wire fence at the top, it will prevent further intrusion.

-High durability, anti-rust, and anti-corrosion, not afraid of rain and high temperature.

-Prevents intrusion of small animals, rodents and stray animals will not enter.

-Visibility, ventilation

-Variety of appearance, such as chain link fence, perforated mesh, 3D fence, etc.

-Color options, such as transparent fences commonly used black, green

anti climb

anti cut security fence

detail drawing

Ⅲ. Which type of anti-climbing fence is right for you?

1. Chain link fence

It is woven by machine into interlocking steel wires. The higher the wire gauge, the finer the corresponding wire. Generally, 9 gauge wire is used for residential and commercial places. Alternatively, you can use thicker wires if you have higher needs. Chain link fences are easy to install and repair and can be replaced by simply cutting off the necessary portion.

2. Wooden Fence

It is an opaque material, so it gives a feeling of environmental protection, sturdiness, and back to nature. However, it is not durable on rainy days or in places where there are sources of fire.

3. Metal hoardings

This is a flexible option that can be reused and installed on steel or wooden posts. It is relatively expensive to install, but it provides permanent stability and less than ideal visibility.

4. Mesh panels

Anti-climbing fences in addition to providing visibility of other fences, can also provide more protection than chain link fences, wire diameter is larger than other fences, and welded into a rectangular shape, providing a more solid barrier.

Therefore, if you are looking for high security and visibility at the same time, anti-climbing fences are the recommended choice.

anti climb fence size

anti climb security fence

Ⅳ. What is the use of anti climb fence?

1. Military, Defense, Prison, Police stations, and courts.

3. Heavy engineering, mining, and industrial sites.

4. Government Electric, utility, and nuclear power plants and public buildings

5. Medical facilities, laboratories, and pharmaceutical companies.

6. Zoos and wildlife sanctuaries.

7. railroad lines, Airport terminals, and shipyards.

9. Schools, stadiums, neighborhood homes. Large private and commercial properties.

Ⅴ. How can I make my anti-climb fence more effective?

1. Install a Barbed Wire Fence on top of the mesh panel.

2. Install Flat Wrap Razor Wire on the top of the panel fence.

3. Installation of Barbed Wire Fence + Razor Wire on top of the mesh panel.

4. Install Razor Wire/Accordion Fence on top.

5. Add Welded Razor Wire Mesh on top of the mesh panel.

6. Add concertina fence.

7. Bend the top of the climbing mesh and bend it inward to use 3D mesh panels.

8. Installation of anti-climb spikes at the top of the fence

gate anti climb

galvanised anti climb fencing

no climb security fence

Ⅵ. Where to buy anti climb fences — WANZHI STEEL

Anti climb fence supplier–WANZHI STEEL is committed to producing high quality Anti Climbing Mesh-Security Fence for our customers, the mesh hole, wire diameter, height, style, and color are all accepted to be customized, and the price is preferential, the quality of the product is guaranteed, we enjoy a good brand reputation, and we have a wealth of experience in exporting, which has earned us a high degree of customer trust because we have always strived to provide more than the customer’s expectations! service. Free sample service is also available.

My WhatsApp: +86 13938459717 (–Click to chat with me–)

My Email: info03@wanzhisteel.com (–Click to email me –)

Related products you may be interested in:

Our factory is located in Anping County, Shandong Province, besides mesh products, we also produce galvanized wire, Annealed Wire, Construction Binding Wire, STEEL REINFORCEMENT BAR and other wire products, you can visit our production workshop online at any time, and you can leave a message on the webpage or WhatsApp to communicate with me about any parameter and specification of the goods.