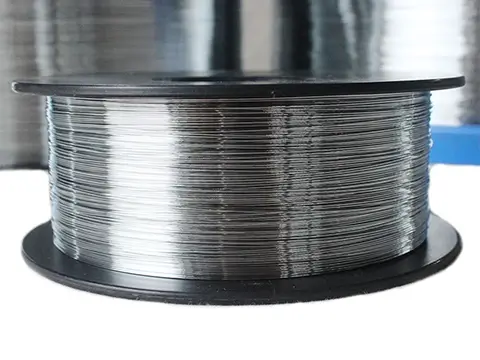

Galvanized Stitching Wire

Galvanized binding wire has always been a reliable choice for durability and strength. From packaging and construction to agriculture and manufacturing, it plays a vital role in securing, bundling and reinforcing materials. It has excellent corrosion resistance and longevity. Whether used for binding books, fences, or tying heavy objects, Wanzhi Steel stocks a large number of commonly used specifications of galvanized stitching wire and accepts customized sizes. If you want to know more, please contact us.

galvanized stitching wire

22 Gauge Galvanized Stitching Wire

Galvanized stitching wire Specifications

| Item | Galvanized stitching wire |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Surface Treatment | Zinc Coated/Galvanized |

| Colour | Silver |

| Tensile Strength | 350-600 N/mm2 |

| Coil Weight | 15, 25, 50,100, 200 Kg |

| Supply form | Roll, spool form |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| Usage | Wire stitched, staples, packing wire, tying wire |

25 gauge stitching wire

stitcher wire spools

Key Features of Galvanized stitching wire

- Strong anti-corrosion performance: Due to the galvanized layer on the surface, it can resist erosion in various environments and extend its service life. No fear of outdoor or humid environments.

- High strength: Galvanized steel wire inherits the characteristics of high strength of steel wire and can withstand greater tension and pressure. Therefore, galvanized staple wire can still maintain a high tensile strength.

- Good wear resistance: The galvanized layer can increase the hardness of the steel wire surface, make the surface of the iron wire smoother, improve its wear resistance, and reduce friction loss.

- Easy to process: It also has good plasticity and processability, and can be easily bent, cut and welded to meet the needs of various processing.

- Aesthetics: The galvanized layer gives the iron wire a silvery-white appearance, making it more beautiful in applications that need to be exposed to the outside.

gi stitching wire

Close view of GI stitching wire

Physical properties

| Physical properties | Typical values/description |

| Tensile Strength | 350-600 N/mm2 (adjusted by material and application, such as low carbon steel or high carbon steel) |

| Elongation | 5%–20% (related to carbon content and coating process, low carbon steel has higher ductility) |

| Zinc Coating | 10–60 g/m² (conventional galvanizing) or higher (such as thick coating for corrosion protection) |

| Diameter Tolerance | ±0.02 mm (precision application) to ±0.05 mm (general application) |

| Hardness | 120–300 HV (Vickers hardness, depending on cold working and annealing process) |

| Bendability | Can be wound/bent 180° without cracks (low carbon steel is better, high carbon steel needs annealing) |

| Corrosion Resistance | Salt spray test (neutral) ≥48–500 hours (the thicker the zinc layer, the stronger the corrosion protection) |

Common wire gauges and sizes

Common specifications include diameter, length, packaging, etc. For example, some galvanized sutures have a diameter of 0.9X0.55mm, while others express the diameter and length per kilogram according to the German Wire Gauge (GWG), American Wire Gauge (ASWG) or British Wire Gauge (BWG). The following is its wire gauge and diameter for your reference.

Cold drawn steel wire different shapes half round, flat wire

AISI 316 Stainless Steel Flat Wire

Stitching Wire Specification Chart

1. Galvanized Round Stitching Wire

| Wire Gauge |

German Wire Gauge (mm) |

m/kg | ASWG (mm) |

m/kg | ft/LBS | BWG (mm) |

m/kg | ft/LBS |

| 21 | 0.80 | 253 | 0.81 | 247 | 368 | 0.81 | 247 | 368 |

| 22 | 0.75 | 288 | 0.73 | 304 | 452 | 0.71 | 322 | 479 |

| 23 | 0.65 | 331 | 0.65 | 384 | 571 | 0.63 | 409 | 609 |

| 24 | 0.6 | 451 | 0.58 | 482 | 717 | 0.56 | 517 | 769 |

| 25 | 0.55 | 536 | 0.52 | 600 | 893 | 0.51 | 624 | 929 |

| 26 | 0.5 | 649 | 0.46 | 767 | 1141 | 0.46 | 767 | 1141 |

| 27 | 0.45 | 801 | 0.44 | 838 | 1247 | 0.41 | 965 | 1436 |

| 28 | 0.4 | 1014 | 0.41 | 965 | 1436 | 0.36 | 1252 | 1863 |

| 29 | 0.37 | 1185 | 0.38 | 1123 | 1671 | 0.33 | 1489 | 2216 |

| 30 | 0.35 | 1324 | 0.36 | 1252 | 1863 | 0.3 | 1802 | 2682 |

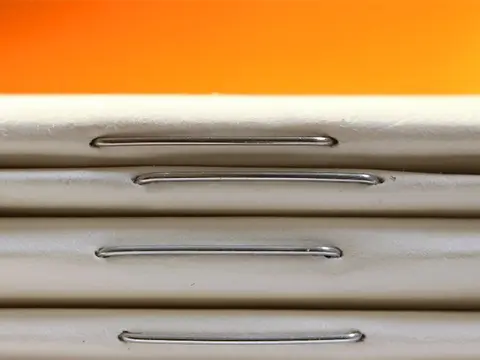

2. Galvanized Flat Stitching Wire

| Wire Diameter |

Size in Inches |

Sizes in Millimeters |

Feet per pound |

*Recommended Thickness of Work |

| 18 x 20 | .047 X .035 | 1.20 X 0.90 | 221 | 5/8″ – 2″ |

| 19 x 21.5 | .041 X .030 | 1.05 X 0.75 | 283 | 1/2″ – 1″ |

| 19.5 x 21 | .037 X .031 | 0.95 X 0.80 | 283 | 1/2″ – 1″ |

| 20 x 24 | .035 X .023 | 0.90 X 0.60 | 408 | Up to 3/16″ |

| 20 x 25 | .0.35 X .021 | 0.90 X 0.55 | 455 | 1/8″ – 5/8″ |

| 21 x 25 | .031 X .021 | 0.80 X 0.55 | 559 | 1/16″ -1/2″ |

stainless steel stitching wire

GI STITCHING FLAT WIRE

3. Examples of wire gauges used in staplers

The majority of the stitching wire used in today’s binderies and in-line stitching operations is 24 and 25 gauge. The difference in size from 24 Gauge (.023”) to 25 gauge (.0204”) is .0026”.

A 24 Gauge wire has 8,496 inches per pound of wire and 25 Gauge has 10,800 inches per pound. This amounts to a 21.3% difference in product yield, which translates into 21.3% more staples if you use 25 Gauge over 24 Gauge. In simpler terms if you imagine a staple or stitch being 1 inch, you would have 2,304 more staples by using the 25 Gauge wire over 24 Gauge.

Recommended wire gauge

- 25 gauge stitching wire’s recommended thickness of work is 1/16 to 7/32 of an inch.

- 24 gauge stitching wire’s recommended thickness of work is 1/16 – ¼ of an inch.

These are only suggestions as paper type, density, coatings, and stitcher setup can change the stitching wire size required.

Galvanized Stitching Wire Flat Wire for Building Materials

0.8-2.5mm Galvanized flat wire for stitching

What are the applications of Galvanized stitching wire?

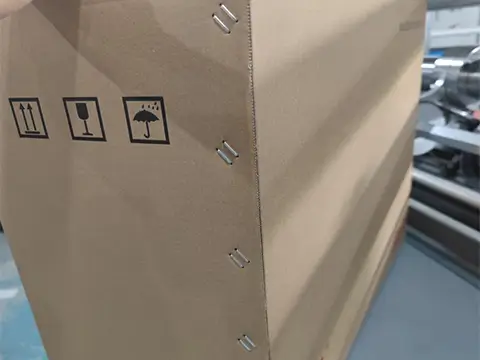

- Packaging industry: fix the edges of cartons and packaging boxes, bundle goods in logistics and warehousing to prevent goods from scattering or damage.

- Building and construction: can be used to fix building templates, and to connect and fix structures such as fences and protective nets.

- Furniture manufacturing: used to fix furniture components such as drawer slides, door panels, etc. Fix the fillings of soft furniture such as sofas and mattresses.

- Agriculture and gardening: fix plant stems, provide support, and prevent lodging. Used to build farmland fences, livestock fences, etc.

- Handicrafts and DIY: Because it is easy to bend and fix, it is often used in the production of handicrafts, such as weaving, beading, etc. It can be used to fix, connect or decorate various DIY materials.

- Automobile manufacturing: galvanized staplers can be used to fix interior parts, wiring harnesses and other components.

- Electronic product manufacturing: fix circuit boards, components, etc. to ensure product stability and reliability

box stitching wire

book binding wire stitching

For flower stand connection

FAQs

1. Q: Do you have your own production factory?

A: Yes, we not only have our own factory, but the products have been put into use in more than 100 countries around the world and have been well received by clients.

2. Q: Can you send us samples?

A: We are pleased to send you the sample to test the quality and market.

3. Q: About your products, could you do it OEM?

A: Yes, OEM and ODM services are available.

4. Q: For the product, could you spray other colors of paint?

A: Yes, color can be customized. We have coating methods such as Vinyl Coated and PVC coated.

5. Q: What are the payment terms?

A: Normally T/T 30% in advance and T/T 70% before shipment.

6. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

7. Q: How does your factory do regarding quality control?

A: We always pay great attention to quality control from the very beginning and every product was tested piece by piece before delivery.

8. Q: Do you have quality certification?

A: Yes, we have CE, SGS, ISO, etc.

round stitching wire FOR SALE

9 gauge galvanized wire in stock

Reliable Galvanized Stitching Wire Manufacturer – Wanzhi Steel

Wanzhi Steel is one of the leading galvanized suture wire suppliers in China. We are an experienced trading company, and compared with well-known galvanized steel coil manufacturers such as Baosteel and Wuhan Iron and Steel, Wanzhi Steel offers more competitive prices for products of the same quality. In addition, we offer a variety of steel products for you to choose from.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Baling Wire, galvanized wire, low carbon wire, Oval Wire, Cold drawn wire, SS wire, Black Annealed Wire, Straight Cut Wire, Construction Binding Wire, and galfan wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

* Leave Us A Message