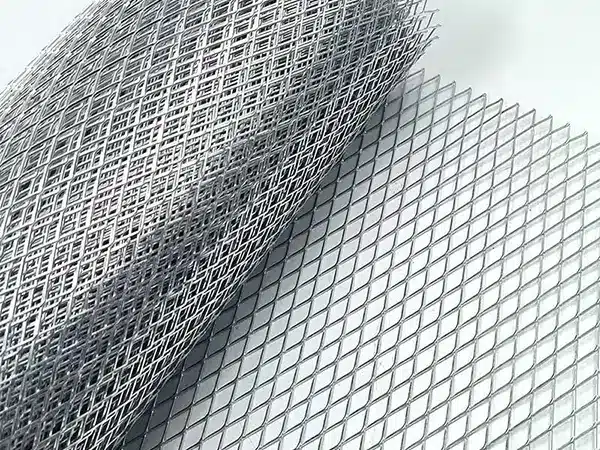

Galvanized Expanded Metal Mesh

Galvanized expanded metal mesh refers to Zinc-coated expanded metal mesh, which is a metal mesh with various diamond openings made by cutting and stretching galvanized steel sheets. It has excellent anti-corrosion performance and mechanical strength. It also offers free passage of light, liquid, sound, and air, while providing a decorative or ornamental effect. Expanded mesh sheets are mainly for decorative facade panels, walkway grates, fencing, automobiles, lathing, and other uses. Wanzhi Steel specializes in the production of high-quality galvanized expanded metal mesh and has an excellent reputation. Size and color can be customized. You are welcome to consult online.

GI Expanded Metal SHEET

HDP Expanded Metal

Specification

| Item | Galvanized expanded metal mesh |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Delivery Time | 15-21 days |

| Surface treatment | Hot dip galvanized |

| Hole shape | Diamond |

| Color | Silver |

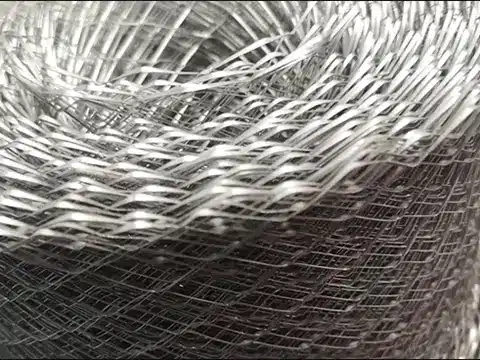

| Supply Form | Sheet or coil |

| Mesh Sheet thickness | 0.5mm-8.0mm |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons |

What is Galvanized expanded metal mesh?

Galvanized Expanded Metal is a steel mesh made by cutting and stretching galvanized steel sheets to form diamond-shaped openings. Hot-dip galvanizing or electro-galvanizing coating ensures excellent corrosion resistance and a long service life. This practical and versatile steel mesh can be used to make screens, fences, window panels, facades, machine guards, etc. Spray-coated decorative expanded metal is often used for shelves, signs, and ceilings. In addition to galvanized steel, it also includes aluminum, carbon steel, and stainless steel.

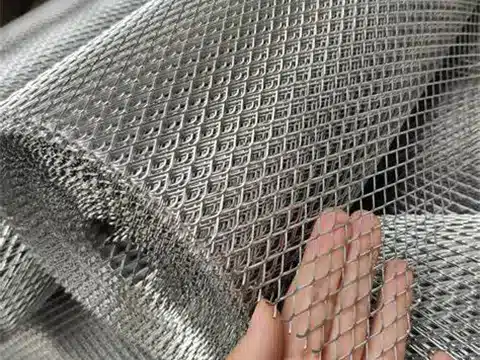

Raised Metal Mesh

Close view of Expanded Metal

What is another name for expanded metal?

Standard expanded metal, also called raised expanded metal, is a versatile material for many different uses. The process of slitting and stretching the sheet metal creates its unique raised pattern of diamond-shaped openings.

What Do Expanded Metal Numbers Mean?

Expanded metal numbers denote the metal’s dimensions and gauge. The first number indicates the metal’s nominal dimension or short way of design (SWOD), and the second number typically indicates the metal’s gauge or weight per 100 square feet.

What Are the Types of GI Expanded Metal?

Classification by material

- Carbon Steel Expanded Metal: Standard option, economical and suitable for general use.

- Stainless Steel Expanded Metal: More corrosion resistant and suitable for harsh environments.

Classification by thickness and wire diameter

- Light expanded metal: 0.5–2 mm thick, lightweight and flexible, suitable for decorative screens or light partitions.

- Medium-thickness galvanized expanded steel mesh: 2–4 mm thick, balanced strength and durability.

- Heavy-duty expanded metal: >4 mm thick, high strength and impact resistance, suitable for heavy-duty applications.

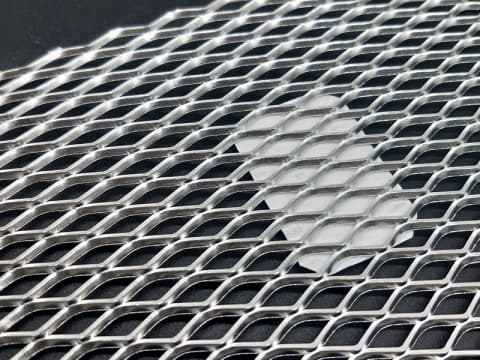

Classification by pattern

- Standard/Diamond Pattern: The most common diamond hole design, the metal at the node is not completely cut off to form an overall strength. The hole pattern is symmetrical, providing uniform ventilation and light transmittance.

- Flattened Pattern: The standard diamond mesh is cold-rolled and flattened, with a smooth surface without burrs, thinned thickness, and safer edges, suitable for human contact scenarios.

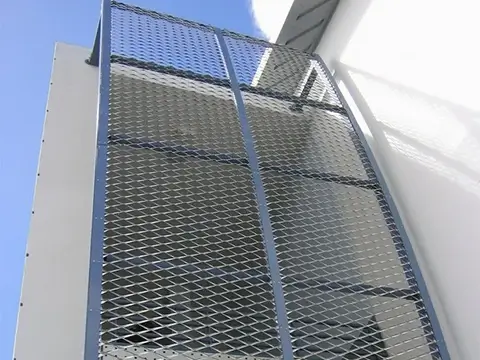

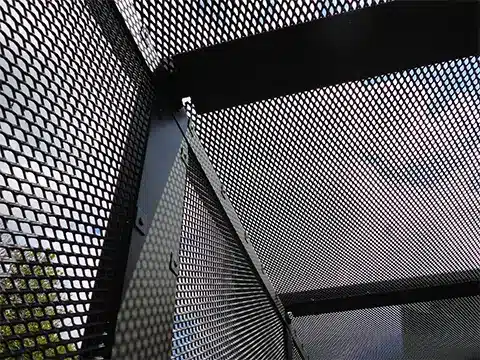

Isolation Fence

Window safety panels

- Micro Expanded Metal: The pore size is extremely small (usually <3mm), and the mesh surface is fine. High-precision filtration or designs that require concealment.

- Hexagonal Pattern: Hexagonal honeycomb structure, light weight and strong pressure resistance. Unique visual, higher light transmittance.

- Bar Grating Pattern: Long strip openings, similar to grilles, excellent drainage and load-bearing performance. Outstanding anti-slip performance.

Classification by galvanizing process

- Hot-dip galvanized expanded metal: Continuously dipped in molten zinc, resulting in a thick, durable coating (80-120 microns). Excellent corrosion resistance. Suitable for outdoor or harsh environments.

- Electro-galvanized expanded metal: Zinc is applied by electroplating, coating (10-20 microns). Lower cost, moderate corrosion resistance, ideal for indoor use.

Classification by manufacturing method

- Uniaxial Expanded Metal: Stretched in one direction to form elongated openings. Used in filters, screens for specific particle separation.

- Biaxial Expanded Metal: Stretched in two directions to form a uniform diamond/square pattern. The most common are fences, floors, etc.

China 0.6-1.2mm Thickness Galvanized Expanded Metal

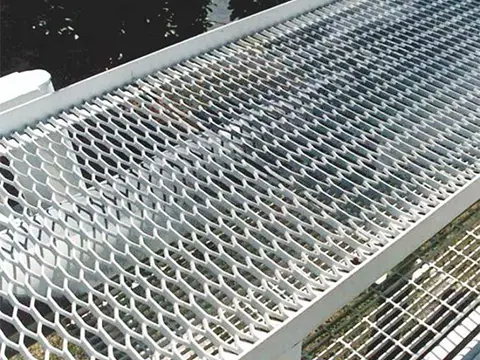

expanded metal catwalk grating

What is expanded metal mesh used for?

- Construction: used as factory, warehouse, school, residential fence, stair tread, industrial platform, balcony guardrail, or as a substitute for steel bars during concrete pouring.

- Decoration and design: building facade sunshade net, ceiling, indoor screen, exhibition display rack, background wall, landscape installation, space modeling, sculpture art.

- Industrial scene: used for machine guards, equipment platform anti-slip floors, workshop partitions, ventilation ducts, sound insulation screens, shelves, storage cages in chemical, food, pharmaceutical, and other industries.

- Traffic and transportation: automobile chassis protection, ship decks, bulkheads, etc., railway guardrails, highway sound insulation screens, lightweight structural components.

- Agriculture and horticulture: animal fences, livestock and poultry fences, orchard protection, vegetable garden isolation, greenhouse and shed support covering nets.

- Safety and protection: making anti-theft windows, prison isolation nets, explosion-proof walls, warehouse shelf nets, or as guardrails, fire passages, escape ladders, etc. for highways and railways.

- Environmental protection and energy: screening equipment for energy mining, chemical plants, landfills, and manufacturing plants.

Stair handrail

Ceiling wall panels

expanded metal floor grating

GI welded mesh VS GI expanded mesh VS Woven Mesh

- GI Welded Mesh: High strength, not easy to deform, suitable for load-bearing scenarios. The mesh is square, the nodes are firm, and the overall rigidity is high. Hot-dip galvanizing (GI) is rust-proof and can be coated with PVC.

- GI Expanded Mesh: One-piece molding, no welding points, lightweight and good air permeability, strong impact resistance. Low cost, suitable for large-area coverage. Hot-dip galvanizing or electro-galvanizing treatment.

- GI Woven Mesh: Metal wires are interwoven in warp and weft, with fine mesh and high filtering accuracy. High flexibility, can be bent and curled. Suitable for curved surface installation.

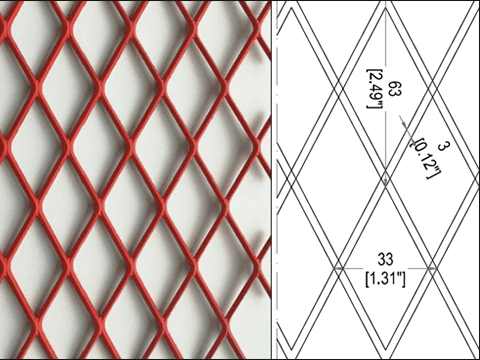

How to Measure Expanded Metal

First, you need to consider whether the metal mesh is raised or flat.

1. Raised expanded metal

In its original form, expanded metal has a raised appearance in which angular strands incline from the plane of the sheet. You’ll want to account for the following measurements:

1) Longway Pitch: Horizontal measurement from center to center based on the size of the tool used during production.

2) Shortway Pitch: Vertical measurement from center to center based on the expansion that occurs during production.

3) Strand Width: Measurement of the width of the angular strand that forms during production.

4) Strand Thickness: Measurement of expanded metal thickness.

Size Measurement

flat GI expanded metal

2. Flattened expanded metal

With flattened expanded metal, measure the longway and shortway aperture in addition to strand width and thickness. Longway aperture refers to the horizontal measurement from one internal aperture point to another. Shortway aperture is the vertical measurement from one internal aperture point to another.

How Do You Read Expanded Metal Sizes?

1. Style: Based on a measurement of the edge of the expanded metal to the straight edge and may include a letter at the beginning to denote the material (for example: “A” for aluminum)

2. Weight: Measured in pounds per square foot

3. Opening Size (in inches): Denotes the metal’s SWOD and long way of design (the diagonal length of the long diamond)

4. Strand Size (in inches): Indicates the strand’s width and thickness

5. Approximate Open Area% %: Represents the approximate area of an irregular region surrounded by curves

Two examples:

| Type of mesh 2.0 mm in thickness | |

| LWD=11 ±0.2 mm | LWO – 7 ± 0.2 mm |

| SWD=8.5 ± 0.2 mm | SWO= 4‘5± 0.2 mm |

| Strand width | 2 ± 0.1 mm |

| Strand thickness | 2 ± 0.1 mm |

| Weight of mesh/m2 | 5.84 kg/ m2 |

| Hardness | HB*57 |

| Yield strength | 235 Mpa |

| Tensile strength | 300 Mpa |

| Elongation | 47 -r 50 % |

Galvanized expanded metal on sale

Galvanized expanded mesh sheet

| Type of mesh SPCC JIS G 3141 with 1.5 mm in thickness | |

| LWD = 11 ±0,2 mm | SV\/D = 9 ± CK2 mm |

| LWO = 8 ±0.2 mm | SWO = 6 ± 0.2 mm |

| Strand width | 1.5 ± 0.1 mm |

| Strand thickness | 1.5 ± 0.1mm |

| Weight of mesh /m2 | 3.07 kg /m2 |

Production process

- Raw material preparation: Choose metal plates such as carbon steel plates and stainless steel plates, and determine the thickness of the plates according to the purpose.

- Cutting: Use a punch or die to cut parallel seams on the metal plate at a preset spacing, and the cut is rhombus or straight.

- Stretching: Mechanically stretch the plate in a direction perpendicular to the cut to expand the cut to form a regular rhombus hole. The metal lattice is extended but remains continuous without welding points.

- Forming: After stretching, it is cut into specified sizes according to needs. Some products need to be cold rolled and flattened.

- Hot-dip galvanizing: Immerse the mesh in molten zinc liquid to form a 80-120μm thick coating, or use electrolyte for electrogalvanizing.

- Post-processing: After cutting the size, it can be further flattened, painted or powder-coated to improve performance.

- Quality inspection: Measure the aperture, length, width, and thickness of the plate, check the quality of the zinc layer, surface defects, bubbling, salt spray test, etc.

Steel Mesh Panel Packaging

Package of Galvanized metal mesh

GI Expanded Metal Mesh For Sale – Wanzhi Steel

GI expanded metal mesh is considered one of the most economical materials for industrial, architectural, and commercial applications. If you have more questions about Galvanized expanded metal mesh, Wanzhi Steel‘s experienced team is happy to help you.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Spring wire, expanded metal lath, Baling Wire, Expanded Metal Grating, and Diamond Mesh Lath for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message