Factors Affecting the Life of Galvanized Wire

Before purchasing galvanized wire, many customers ask us the question, how long does your galvanized wire last? In fact, the service life of galvanized wire is affected by many factors, such as the production process, the quality of raw materials, the zinc content, and the environment in which it is used. Next, Wanzhi Steel will provide you with a detailed introduction. Please read on to learn more!

GI Wire surface

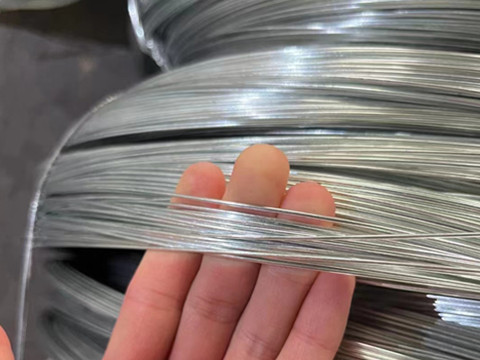

Gi wire Coils

Four Factors that Affect the Life of Galvanized Wire

1. Production Process

There are two production processes for it, hot-dip galvanizing and electro-galvanizing. The zinc layer of hot-dip GI wire is usually thicker than that of electro-galvanized wire. Wanzhi Steel can produce hot-dip galvanized wire with a zinc layer of 40 – 350g/m², while electro-GI wire has a zinc layer of only 8 – 25g/m². The thickness of the zinc layer often determines the corrosion resistance of the wire. This also means that hot-dip GI wire will last longer than electro-galvanized wire.

Hot Dipped Galvanized

Electro Galvanized

2. Raw material quality

The quality of raw materials used in the production process of the manufacturer directly affects its service life. Wanzhi Steel, as a reputable GI steel wire manufacturer, uses high-quality Q195 low-carbon steel wire as raw material. The hot-dip GI wire we produce is bright in color, soft in texture, and has excellent corrosion resistance. According to the feedback from our old customers, the quality of GI wire produced by our factory is better than many peers.

3. Zinc content

It with a zinc content of 30g/m² will not rust for 5 years under normal use conditions. In addition, GI with a zinc content of 100g/m² can be extended to 7 years without rust. GI wire with a zinc content of 235g/m² will not rust for up to 10 years. Therefore, if you want the galvanization steel wire to have a longer service life, you can choose a wire with a higher zinc content.

Finished GI Wire

Wanzhi Steel Factory

4. Environment Of Use

The environment of use includes many aspects such as air, soil, and temperature. The following conditions can shorten the life of GI iron wire.

1. When it is used in high or low humidity and is exposed to salt, acid, or industrial contaminants;

2. If it is buried in the soil, it will be exposed to more moisture, which will also affect its longevity. (The magnitude of the effect depends greatly on the type of soil and overall conditions);

3. When it is combined with corrosive factors such as humidity and industrial pollution, it accelerates its corrosion rate, resulting in a shorter life span.

In addition, the environment in which the gil wire is stored can also affect its longevity. If you purchase a large quantity of GI steel wire, it is best to store it in a dry, well-ventilated warehouse. Also, remember not to store corrosive items with GI wire.

GI wire for sale

Galvanized Wire Packaging

Galvanized Wire Supplier – Wanzhi Steel

These are the four factors that affect the life span of GI wire. If you are going to purchase GI wire shortly, you can contact Wanzhi Steel. We will recommend the right type of wire for you according to your actual application. Below are the specifications of the gi steel wire we provide for your reference.

| Product | Hot GI Wire | Electro GI Wire |

| Diameter | 0.5 – 5.0 mm | 0.25 mm – 5.00 mm |

| Zinc Coated | 40 – 350g/m² | 8 – 25g/ m² |

| Tensile Strength | 350 – 550N/mm² | 350 – 550N/mm², 680 – 850N/mm² |

| Elongation Rate | 15% | 10% – 25% |

| Coil Weight | 1 kg – 1000 kg or as per your requirements | |

WANT A QUOTE?

![]() Whatsapp CHAT DIRECTLY / EMAIL DIRECTLY

Whatsapp CHAT DIRECTLY / EMAIL DIRECTLY

Leave Us A Message