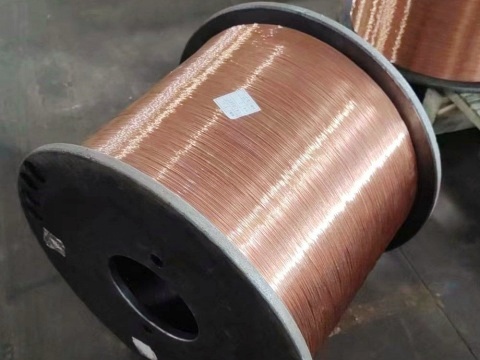

Copper Coated Aluminum Wire

Material: Aluminum, copper

Thickness: 0.15 mm – 1.2 mm

Delivery Time: 10-15 days

Transportation: By sea, by land

Copper Coated Aluminum Wire

Copper-coated aluminum wire, also known as CCA wire, consists of an aluminum core and a copper outer layer. It combines the lightweight and low-cost benefits of aluminum with the electrical conductivity and weldability of copper. It is widely used in high-frequency transformers, automotive wiring harnesses, coaxial cables, and electronic components. The “skin effect” of high-frequency currents gives it electrical performance close to that of pure copper, making it an effective alternative to pure copper wire. Wanzhi Steel stocks CCA wire in various diameters, customizable copper layer ratios, and packaging methods. If you are interested, please contact us for more information.

Industrial Grade PEW 130,155 CCA Winding Wire

Copper Clad Aluminum CCA Cable

Specification

| Item | Copper Coated Aluminum Wire |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Color | Copper |

| OEM/ODM | Available |

| Application | Transformer, Electronics, Computers, Industrial, Electric |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

0.45mm Aluminum Enameled Copper Wire Manufacturer

0.10mm to 0.50mm Copper Clad Aluminum Wire

Core Features

1. Lightweight and Low Cost

Copper-clad aluminum wire boasts a density of 37%-40% of pure copper wire of the same diameter, significantly reducing weight and costing at least 40% less than pure copper wire. It is suitable for motor and electronic equipment manufacturing.

2. Electrical Performance Suitable for Multiple Scenarios

DC resistivity is 1.45-1.5 times that of pure copper. Due to the skin effect, transmission performance at high frequencies is similar to that of pure copper wire. For the same cross-sectional area, the current carrying capacity is 2%-5% higher than that of pure copper, meeting most power needs.

3. Mechanical and Physical Properties

The copper-aluminum metallurgical bond is achieved through a cladding welding process, resulting in a strong, flexible, and high tensile strength. This facilitates installation and welding, and improves oxidation and corrosion resistance.

4. Unique Anti-theft Features

Copper, a precious metal, is susceptible to theft. However, copper-clad aluminum wire is difficult to separate from its aluminum. In high-security scenarios, this reduces theft losses and ensures the safety of equipment and wiring.

CCA Wire China Professional Wholesaler

CCA wire for voice coil

Application

1. Power and Electrical Industry

It is used in high-voltage transmission lines, substation busbars, and distribution systems. Its conductivity is close to that of pure copper, saving 65%-80% of copper usage. It is also a conductor material for new energy vehicle battery packs and cable conductors for energy storage devices.

2. Electronic Equipment

It is used to make windings for high-frequency transformers and conventional transformers. It is also suitable for windings for household appliance motors (such as compressors and fans), industrial motors, and new energy vehicle motors.

3. Communications and Audio and Video

It can be used as a conductor material for coaxial cables used for cable television signal transmission and complies with the SYWV-75-5 industry standard. It can also be used to make audio cables and shielded cables for connecting precision electronic components such as audio equipment and optical drives.

4. Other Applications

It can be used to make engineering wires, suitable for industrial equipment cables, and engineering conductors. It can also be used for degaussing coils in electromagnetic equipment. It can also be used in automotive non-power wiring harnesses and RF cable shielding mesh.

Wide range of applications

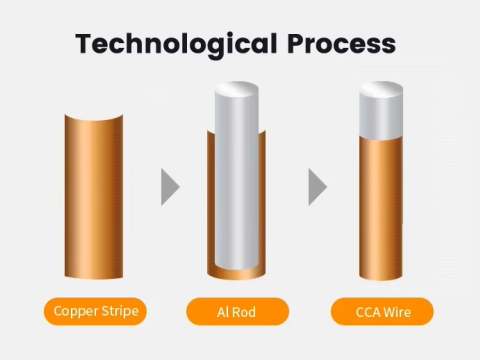

Manufacturing Process

Currently, the mainstream advanced processes are clad welding and electroplating.

1. Clad Welding Process

This process involves: cleaning the aluminum rod → wrapping with copper strips → heating/annealing → drawing/annealing. In short, the aluminum rod is wrapped with copper strips via forming rollers; then heated or annealed to form a metallurgical bond, and then drawn and annealed to the desired fine wire specifications.

Advantages: Extremely high bond strength, uniform and controllable copper layer thickness (typically with varying copper volume ratios such as 10%, 15%, and 20%), and stable performance.

2. Electroplating Process

Process: A clean aluminum rod, acting as the cathode, is immersed in an electrolyte containing copper ions. Direct current is applied, reducing the copper ions on the rod surface, depositing a uniform copper layer.

Advantages: The process is relatively simpler, and the coating is thinner and more precise.

Copper clad aluminum wire cross section

CCA Wire Process

Copper Clad Aluminum (CCA) vs. Copper Clad Steel (CCS)

| Features | Copper-clad Aluminum Wire (CCA) | Copper Clad Steel Wire(CCS) |

| Core Materials | Aluminum | Steel |

| Core Properties | Lightweight, good conductivity (better than steel), and flexible | High strength, high tensile strength, poor conductivity |

| Main Advantages | Lightweight, good high-frequency performance, and excellent flexibility | Extremely high mechanical strength, fatigue resistance, and rodent resistance |

| Conductivity | Approximately 30% IACS (compared to the International Annealed Copper Standard) | Approximately 30-40% IACS (although strength is the primary consideration in practical applications) |

| Main Applications | High-frequency signal transmission, automotive wiring harnesses, winding wire, and lightweight cables | Used for high-intensity signal transmission, such as armored cores in overhead fiber optic cables, telephone lines, tensile stress applications, and long-span overhead lines |

| Criteria for Selection | When conductivity and weight are primary considerations | When tensile strength and durability are primary considerations |

How to choose?

- Choose copper-clad aluminum (CCA): If you need to transmit signals (especially high frequencies) and want to reduce weight and cost.

- Choose copper-clad steel (CCS): If you need a cable that can withstand significant tensile stress, is used for outdoor aerial installation, or requires bite resistance.

Wanzhi Steel CCA CCS CCAM TCCAM TCCS workshop

Copper Coated Aluminum Wire Manufacturer-Wanzhi Steel

Copper-coated aluminum wire, with its superior performance balance, has become an ideal alternative to pure copper conductors in the global industrial sector. As a professional wholesale manufacturer, Wanzhi Steel has a complete production chain and a strict quality control system. Our products meet international standards and offer customized copper layer ratios, wire diameters, and specialized export packaging. We also provide cost-effective solutions and highly competitive pricing. Let us help you gain a competitive advantage in the market.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001 certified steel factory, located in Hebei Province, China, specializing in the production of Galvanized wire, Annealed wire, CCS Wire, Copper wire, Galfan wire, Brass wire, Aluminum wire, CCAM /TCCAM/TCCS Wire, with a monthly output of 1,800 tons. With high-quality products and good services, the products have been exported to more than 120 countries around the world.

Leave Us A Message