Color Coated Coil

Thickness: 0.02-1.2mm

Width: ≤1500mm

Coating: PE, SMP, HDP, PVDF(top11-35μm, bottom5-14μm)

Color: RAL color

Color Coated Coil

Color-coated coils commonly use cold-rolled steel sheets, hot-dip galvanized steel sheets, and galvalume steel sheets as their base materials. They are manufactured by continuously roller coating a primer and a topcoat onto the surface. Wanzhi Steel supplies full-size color-coated coils for applications in the construction, home appliance, and automotive industries. We also offer a wide variety of colors and finishes, including matte, glossy, frosted, wrinkled, embossed, and textured. Custom coil weights ranging from 3 to 5 tons are available. If you’re interested, welcome to contact us.

Embossed Wrinkled PPGI PPGL Color Coated Steel Coils

RAL5015 PPGI Coil China manufacture

Specification

| Item | Color coated coil |

| Place of origin | Shandong, China |

| Delivery Time | 18-28 days |

| Material | SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z/Q195-q345 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Certification | ISO 9001, SGS, ABS, BV |

| Coil Weight | 3-5 tons |

| Paint Surface | Matt/wrinkled/glossy/embossed/textured |

| Aliases | Color Zinc Coated Coil, Prepainted Galvanized Steel Coil, Color Galvalume Steel Coil, PPGI Coil, PPGL Coil |

| Monthly Production | 5000-10000 tons |

| Sample | Free Available |

| MOQ | 10 Tons |

| Packages | Standard Seaworth Packing |

| Payment | T/T 30% prepayment |

| Transport | By sea, by land |

PPGI Pre-Painted Galvanized Four coating types:

1. Polyester (PE)

Good adhesion, rich colors, a wide range of formability and outdoor durability, medium chemical resistance, and low cost.

2. Silicone-modified polyester (SMP)

Good coating hardness, wear resistance, heat resistance, good outdoor durability and anti-powdering, average light retention and flexibility, and medium cost.

3. High-durability polyester (HDP)

Excellent color retention and UV resistance, excellent outdoor durability and anti-powdering, good coating adhesion, rich colors, and excellent cost performance.

4. Polyvinylidene fluoride (PVDF)

Excellent color retention and UV resistance, excellent outdoor durability and anti-powdering, good formability, good stain resistance, limited colors, and high cost.

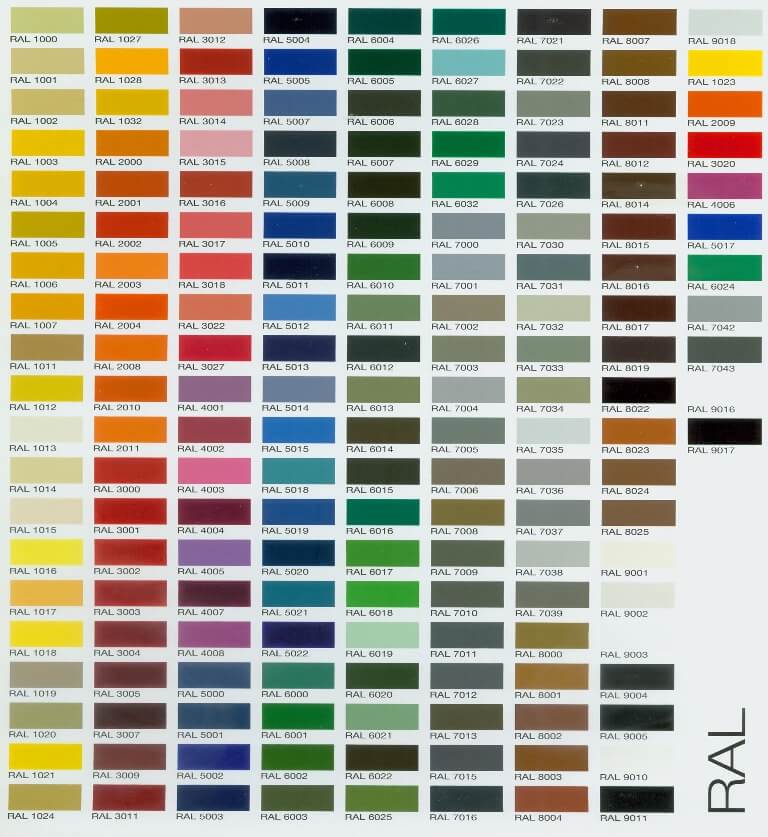

The Most Popular Color

RAL color card

The most customized colors are RAL6005 green, RAL 5015/RAL5005 blue, RAL3020/RAL3005 red, RAL9003 white, RAL9004 black. If you like other colors, please send us the RAL color code or sample and we will design according to your requirements.

Production Video

Weight Calculation Formula

Color-coated Steel Coil

Thickness (mm) × width (m) × total number of meters (m) × 7.85 = Weight (kg)

Note: 7.85 is the density of steel, meaning each cubic meter of steel weighs 7.85 kg.

Color-coated Aluminum Coil

Thickness (mm) × width (m) × total number of meters (m) × 2.71 = Weight (kg)

Note: 2.71 is the density of aluminum, meaning each cubic meter of aluminum weighs approximately 2.71 kg.

Product Advantages

glossy ppgi steel coil galvanized DX51D

1. Excellent corrosion resistance: Lifespan is 13 years in heavy industrial areas, 50 years in coastal areas, 104 years in suburban areas, and 30 years in urban areas.

2. Price comparison: Color-coated carbon steel coil < PPGI < PPGL < color-coated aluminum coil, lightweight and durable.

3. Reliable and stable: The zinc or aluminum-zinc layer is tightly bonded to the substrate, becoming an integral part of the steel surface, facilitating painting. The paint is UV-resistant, maintaining its vibrant color for a long time.

4. Time-saving and labor-saving: The metal material is impact-resistant and scratch-resistant, allowing for easy cutting, perforation, and stamping. It also makes installation and transportation easier.

5. Aesthetically pleasing: Wanzhi Steel offers a variety of colors and finishes to meet diverse design requirements.

Application

1. Roofs, Walls, and Facades

Wave-shaped roofs for logistics warehouses and steel-structured factories, exterior walls of industrial parks, decorative facades of shopping malls, and lining panels for building curtain walls benefit from their weather and corrosion resistance.

2. Automotive Industry

Used in the stamping and manufacturing of side panels and roofs for trucks and trailers, floors and siding for buses and RVs, and structural components such as doors and hoods, thanks to its lightweight and durable properties.

3. Home Appliances and Home Materials

For example, it provides scratch-resistant, easy-to-clean surfaces in refrigerators, washing machines, and air conditioner housings, oven and microwave oven linings, cabinets, filing cabinets, billboards, and whiteboards.

4. Foam Sandwich Panel Raw Material

A foam core is filled between two layers of colored steel sheets to create a “sandwich” structure. Applications such as cold storage walls and roofs, construction site sheds, and workshop partitions benefit from its lightweight, thermally insulating, and soundproof properties.

Blue corrugated roof panel

Billboard writing board

Grass pattern color coated sheet

Different surface treatments

- Normal Surface: Regular surface with different colors, according to RAL codes.

- Matt Surface: Surface is matt, which is not smooth.

- Designed Patterns: Such as flower printing, brick grain, wooden grain, camouflage, traffic sign warning tape, etc.

- Wrinkled Surface: The surface is wrinkled or embossed with different patterns.

We also provide orange peel, frosted, textured, glossy, and other surface treatment services.

Orange peel and embossed surfaces

Matt and frosted surface

Manufacturing process

1. Cleaning: Clean the base metal coil to remove any oil, dirt, or oxides.

2. Pretreatment: Chemical pretreatment is performed to enhance the adhesion of the coating.

3. Priming: Primer is applied to provide additional corrosion resistance.

4. Topcoat: The final color coat is applied, usually followed by a protective clear coat.

5. Curing: The coated coil is baked in an oven to cure the paint and ensure durability.

6. Inspection: measure coating thickness, check surface flatness, and test whether various indicators meet process standards.

High-quality galvanized steel substrate

Coating Structure Type

| Coating structure type | Upper surface coating | Lower surface coating | Number of bakes | Features |

| 2/1 | Two coats | One coat | Twice | Single-layer back paint, poor corrosion resistance and scratch resistance, but good adhesion, suitable for sandwich panels. |

| 2/1M | Two coats | Two coats | Twice | Double-layer back paint, good corrosion resistance, scratch resistance, and processing and forming properties, good adhesion, suitable for single-layer corrugated panels and sandwich panels. |

| 2/2 | Two coats | Two coats | Twice | Double-layer back paint, good corrosion resistance, scratch resistance, and processing and forming properties, but poor adhesion, suitable for single-layer corrugated panels. |

Textured PPGI wood grain steel coil

Wood grain PPGI steel coils China Manufacturer

Color Coated Coil Price

In general, the price of color-coated coils is determined by: raw material cost, coating type, plate thickness, and color factors.

For example, Ordinary polyester coated color-coated coils, High-end PVDF coated color-coated coils, and Aluminum-based color-coated coils has different prices.

The average price is 450-700 USD/ton, for complex craftsmanship price is 650-800 USD/ton.

If you want to know the latest price,

please contact us now. We will reply in 8 hours.

Note:

Cold-rolled steel substrate: lower price. Galvanized steel substrate: medium price, better corrosion resistance. Aluminum substrate: higher price, lightweight, and corrosion-resistant.

White color coated ZAM coil

RAL 9016 white ppgi coil

Color coated coil VS Galvanized Coil VS Stainless Steel Coil

| PRODUCT | Advantages | Disadvantages | Price comparison |

| Color Coated Coil | Various colors, corrosion resistance, strong weather resistance, can be used directly without secondary coating | Special coatings are more expensive. | Medium (depending on coating and substrate) |

| Galvanized Coil | Good corrosion resistance, low price, suitable for general anti-rust needs | Single appearance (silver-gray), additional painting is required to meet aesthetic requirements. | Lower (about 20-30% cheaper than color coated coil) |

| Stainless Steel Coil | Extremely strong corrosion resistance, high-end appearance, long service life | Expensive, heavy, difficult to process | Higher (2-3 times the price of color coated coil) |

Metal Coil Selection Advice

- Limited budget and low aesthetic requirements: Choose galvanized coils or ordinary cold-rolled coils, and then paint as needed.

- Need high weather resistance and aesthetics: Choose color-coated coils, especially PVDF coatings.

- Lightweight and high corrosion resistance: Choose aluminum coils or stainless steel coils, but consider the cost.

Color coated coil Package

color coated coil inner package

Z275 galvanized steel coils sheet DX51D Q235

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer.

Q: Can we visit your factory?

A: Very welcome, we will pick you up once we get your schedule.

Q: Do you have quality control?

A: Yes, we have gained SGS authentication, and CE ISO.

Q: Can you arrange the shipment?

A: Of course, we have a fixed freight forwarder, can get the best price from most shipping companies, and provide professional service.

Q: How long is your delivery time?

A: If it is in stock, it is usually 7-14 days. If it is not in stock, it is 25-45 days, depending on the quantity.

Q: What is your payment term?

A: TT ,LC ,Western Union

Q: Can we get the some samples? Is it charged?

A: Yes, you can get available samples from our stock. Real samples are free, but customers need to pay for the shipping.

SGCC Dx52D PPGL Color Coated Coil

Military camouflage print SGCC ppgi coil

Mongolia color-coated coils project

Color Coated Coil Manufacturer – Wanzhi Steel

Our main products are GI/GL steel, HRC/CRC carbon steel, PPGI/PPGL steel, aluminum, SS steel, corrugated board, roofing sheet, section steel, angle steel, channel steel, as well as silicon steel, guardrails, steel sheet piles, etc. Supply form: plate, coil, wire, strip, mesh.

We are an ISO 9001 certified factory located in Shandong, China, with a monthly output of 1,600 tons. We have extensive export experience and a mature team. With our high-quality products and attentive service, our products have been exported to 120 countries worldwide. If you are interested, welcome to contact us.

Leave Us A Message