Black Annealed Baling Wire

Black annealed baling wire, also called annealed iron wire or soft iron wire, is made of low-carbon steel. It undergoes annealing (heating and slow cooling) then oil-coating for anti-rust and smooth machine feeding. With good flexibility, high tensile strength, and low hardness, it’s easy to bend, fitting various binding needs, and has basic anti-rust properties. Its wire gauge ranges from 5#-38# (0.17-4.5mm), widely used in construction, agriculture, and manufacturing, as well as daily repairs. Wanzhi Steel is a manufacturer of high-quality annealed baling wire. We offer baling and binding wire in all sizes and shapes. If you are interested, please feel free to contact us.

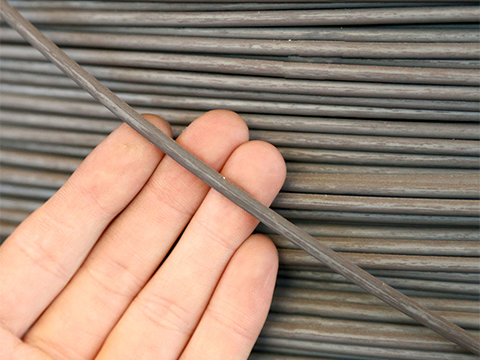

close view of black Annealed wire

Annealed baling wire surface

Specfication

| Item | Black annealed baling wire |

| Place of origin | Hebei, China |

| Type | Loop Tie Wire, Single/Double loop bale tie wire, Binding Wire |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Surface treatment | Annealed |

| Color | Black |

| Length | 1200mm to 6000mm (4 feet to 20 feet), Customize |

| Packing | Wooden case, wooden pallet, or as per the client’s request |

| MOQ | 5 Tons |

| Bundles | 20kg -1000kg/coil or 100- 125 pcs/bundle, as the client’s request |

| Sample | Free Available |

| Payment Methods | TT 30% prepaid, 70% paid before shipment |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Certification | ISO 9001, SGS, ABS, BV |

| Main Use | Binding wire, tie wire |

Q195 Hot rolled cold drawn annealed Wire

black annealed tie wire

Key Features

- Excellent Flexibility: Annealing effectively eliminates internal stresses in the steel, making it soft and resistant to breaking when bent.

- Moderate Strength: A wide range of tensile strength (350-780 N/mm²) ensures secure packaging without compromising handling due to excessive rigidity.

- Excellent Rust Prevention: The surface features a natural black oxide film and is coated with anti-rust oil, providing basic protection and effectively slowing rust during storage and outdoor use.

- Smooth Surface: The treated wire has low friction, allowing for smooth threading and tightening during packaging and bundling, preventing snagging and protecting the surface of the goods.

- Cost-Effective: Compared to other products like galvanized wire, it offers lower production costs and a more economical price, making it a cost-effective solution for everyday heavy-duty packaging needs.

- Excellent Ductility: High elongation at break (>12%) ensures moderate stretching when tightened and under pressure, rather than sudden breakage, ensuring a safe and reliable packaging process.

- Easy to operate: Combining flexibility and strength, it is suitable for both manual operation and automated baling machinery. It is widely used in agriculture, waste recycling, and construction.

Full diameter supply

Black Annealed Iron Wire

Application Areas

Waste Recycling Industry

Waste Paper Baling: Bundling large waste paper bales, loose textiles such as cardboard, old clothing, and fabric, as well as scrap metal such as scrap iron and aluminum cans, for easy transportation, storage, and weighing.

Agriculture

- Hay/Straw Baling: Bundling square or round bales of hay and straw for livestock. For example, 2.6mm (Ga. 12) black annealed wire is used to bind square hay bales, each strand of which can withstand over 500kg of tension.

- Cotton, Straw, and Forage Baling: Bundling agricultural waste, straw, cotton bales, and forage bales to prevent them from falling apart.

Construction Industry

- Rebar Baling: Bundling rebar of different sizes together for easy transportation. For example, 2.0mm black annealed wire is used to secure a pile of rebar to prevent it from tipping over.

- Building Material Baling: Bundling long materials such as steel pipes and aluminum, as well as bricks, tiles, wood, gypsum board, and scaffolding, for easy handling and storage.

Manufacturing and Logistics

Balancing metal chips and scraps; bundling wood boards, strips, or pallets; bundling finished fabric rolls or yarn; temporarily securing engine parts and vehicle frames; and horizontally bundling cardboard and wooden boxes within trucks or containers.

Annealed Wire for Barbed Wire

Hay baling wire tying

Fixed Rebar

Municipal, Household, and Emergency Sector

- Bundling compressed garbage, saplings, shrubs, or flowers; securing vines; bundling fences; securing pipes in garages or storage rooms; and repairing fences.

- Structural support for metal sculptures, woven ornaments, or DIY projects; bundling relief supplies such as tents and food boxes; securing damaged structures; and constructing temporary shelters.

Production Process

- Raw Material Preparation: Select low-carbon steel wire, remove defective wire, and cut it into fixed billets.

- Wire Drawing: Use a wire drawing machine and die to draw the billet step by step, reducing it to the target wire diameter (e.g., 1.2-4.0mm) and improving the surface finish.

- Annealing: Heat at 650-850°C under inert gas, hold for 1-3 hours, then slowly cool to eliminate internal stress, reduce hardness, and improve flexibility.

- Surface Film Formation: After cooling, a black oxide film forms on the surface, imparting a “black annealed” appearance and providing preliminary rust resistance.

- Cutting/Coiling: Cut to fixed lengths or wind into coils/spools as required.

- Quality Inspection: Test wire diameter, tensile strength, flexibility, and appearance, and remove substandard wires.

- Packaging and Warehousing: After moisture-proof packaging, the wire is stored in a dry warehouse pending delivery.

SAE 1008 wire rod 5.5mm mild steel wire rods

Annealed wire during the drawing process

Galvanized baling wire vs Black annealed baling wire

| Comparison Dimension | Galvanized baling wire | Black annealed baling wire |

| Rust resistance | Strong | Weak |

| Strength | High | Medium |

| Flexibility | Medium | Excellent |

| Appearance and finish | Silver-gray, smooth surface, no visible impurities | Gray-black/black with a uniform oxide film on the surface |

| Cost | High | Low |

| Application scenarios | Suitable for wet/outdoor/lightly corrosive environments | Suitable for dry indoor environments |

Note: If you need higher rust resistance for long-term outdoor use, galvanized binding wire is recommended. If you need indoor use or are looking for a lower price, annealed baling wire is recommended.

Common types

- Straight Cut Wire: The most basic form of wire. It is straight and coated with rust-proof oil. It can be bent into a specific shape (such as a U or O) using a machine.

- Loop Wire/Eye Wire: Wire with both ends bent into a closed loop, creating a fixed-size ring. The ring diameter can be customized and is used for quick bundling.

- U-shaped Wire: Straight black annealed iron wire bent into a “U” shape and secured by wrapping or tensioning.

- Twisted Wire: Two or more wires twisted together to create a twisted shape for increased strength. Used for heavy-duty baling of scrap metal and mechanical parts.

Single Loop Baling Wire

Galvanized U-shaped Tying Wire

Black Annealed Cutting Wire

Diameter Selection Guide

- Agriculture: Baling hay/straw/cotton, 2.6mm (12-gauge) to 3.2mm (10-gauge).

- Recycling & Waste: Baling waste paper/plastic/metal scrap, 3.0mm (11-gauge) to 3.5mm (9-gauge).

- Building & Construction: For securing rebar/pipes, scaffolding, etc., 2.0mm (14-gauge) to 2.6mm (12-gauge).

- Logistics: Cargo reinforcement/pallet securing. Recommended wire diameter: 2.0mm (14-gauge) to 3.0mm (11-gauge).

- Industrial Manufacturing: Baling textiles/cloth, 1.6mm (16-gauge) to 2.0mm (14-gauge).

- Municipal & Environmental Protection: 2.5mm (13-gauge) to 3.5mm (9-gauge).

- Daily Life & Crafts: Home repairs/handicrafts/DIY, 1.2mm (18-gauge) to 2.0mm (14-gauge).

Packaging Methods

- Coil: Wire is tightly coiled into a flat, round disc. This provides simple packaging, low cost, and convenient storage.

- Spool: Wire is wound onto a removable plastic or wooden spool with a center hole. This prevents tangling and allows for smooth payout.

- Straight Lengths: Wire is cut to specific lengths and bundled together, eliminating the need for cutting, ensuring easy handling and consistent lengths.

Small roll packaging

Annealed wire in spool packaging

89 tons of Fiji Straight Cut Wire Project

Black annealed baling wire Manufacturer-Wanzhi Steel

In summary, the black annealing baling wire is your ideal solution for efficient and economical baling. Combining exceptional flexibility, sufficient strength, and basic rust resistance, it’s particularly well-suited for processing waste paper, hay, and building materials, significantly improving your efficiency and effectively controlling costs. Choosing Wanzhi Steel means choosing reliable quality at a competitive price.

Wholesale Annealed Q195 Carbon wire

Black annealed wire storage

Annealed baled wire shipped to Türkiye

Why Choose Wanzhi Steel?

- Our annealing and packaging line is made of high-quality low-carbon steel, with continuous bright annealing, high flexibility, and coated with anti rust oil.

- Accepting extensive customization, covering various wire diameters. Support small orders of 3 tons and large orders of 1000 tons.

- The production process implements three-level quality control, with multiple inspections from raw materials to finished products. The products have passed ISO 9001, ASTM A641, SGS, and CE certifications.

- Our multilingual service team responds within 10 hours and offers direct factory prices. The price per ton of 2.0mm annealed packaging wire is only 60% of that of galvanized steel wire.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized binding wire, Stainless steel tie wire, low carbon steel wire, Galfan Wire, Cold drawn wire, high tensile wire, and Baling Wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message