A142 Mesh

A142 mesh is a welded steel mesh that complies with British standards (BS 4483). It is constructed from 6mm diameter steel wires welded vertically and horizontally at 200mm intervals. With a tensile strength of 500MPa, it is primarily used for reinforcing concrete slabs, floors, and building structures, effectively enhancing bearing capacity, controlling cracks, and simplifying construction. Wanzhi Steel is a high-quality welded steel mesh manufacturer in China. We stock a large inventory of A142/A393/A252/C503 BRC mesh and other steel meshes. If you are interested, please contact us for more information.

a142 fabric reinforcement Mesh sheet

a142 steel mesh

Specification

| Item | A142 mesh |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Processing Service | Bending, Welding, Cutting, etc |

| Type | Welded Mesh |

| Hole Shape | Square |

| Aliases | Reinforcing Welded Rebar Wire Mesh |

| Type | Threaded, non-threaded |

| Mesh Size | 1m × 2m ~3m × 6m |

| Width | Customizable |

| Length | Customizable |

| Surface Treatment | Black Wire, Cold Drawn, Galvanized, powder coated, Epoxy coated |

| Application | Highway, bridge deck pavement, airport runway, house building, etc |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Features

High Strength and Excellent Mechanical Properties

Using cold-rolled ribbed steel bars with a tensile strength of 500 MPa, this product offers excellent reinforcement. The ribbed structure provides strong bonding with concrete, enhancing efficiency.

a142 reinforcing mesh

Galvanized A142 rebar mesh for Building

Excellent Structural Stability

Rebars are resistance spot-welded to form a uniform mesh structure, evenly distributing load stress, effectively suppressing concrete cracking, and improving structural integrity.

Efficient and Convenient Construction

The finished mesh can be laid directly, significantly reducing the time and labor required for tying rebar. Its high rigidity ensures it resists shifting during the pouring process.

Stable and Reliable Quality

Fully automated factory production eliminates human error and ensures highly consistent product dimensions, quality, and mechanical properties.

Economical, Practical, and Standardized

Although the cost per material is slightly higher, the savings in labor and construction time reduce overall costs. Widely used in flooring, slabs, and other applications, this product is an extremely cost-effective choice.

Application

Made of high-strength steel bars welded together using an electric welding process, it is designed to enhance the tensile strength and structural stability of concrete and is commonly used in construction and infrastructure.

Construction

It is commonly used in the construction of concrete floors, foundations, and walls. Examples include ground reinforcement for balconies and terraces, and foundation paving for lightweight structures.

road concrete reinforcing mesh

Bridge steel structure

Tunnel wall and pavement reinforcement

Roads and Bridges

It can be used for paving sidewalks, bike paths, and residential roads. In bridge construction, the mesh can be used as the bridge deck pavement and to reinforce piers and abutments.

Landscape

It can be used to construct garden paths, courtyard surfaces, and landscaped terraces, such as park walkways and scenic area boardwalks.

Small Buildings

Small projects include garages, warehouses, transfer stations, and canopies. It can be used to reinforce floors, walls, and roofs, making it an economical and practical building material.

Common types of welded steel rebar mesh

- A98: Made of 5mm diameter steel bars welded at 200mm intervals. The total cross-sectional area of longitudinal reinforcement per meter is 98 mm².

- A142: Made of 6mm diameter steel bars welded at 200mm intervals. The total cross-sectional area of longitudinal reinforcement per meter is 142 mm².

- A193: Made of 7mm diameter steel bars welded at 200mm intervals. The total cross-sectional area of longitudinal reinforcement per meter is 193 mm².

- A252: Made of 8mm diameter steel bars welded at 200mm intervals. The total cross-sectional area of longitudinal reinforcement per meter is 252 mm².

- A393: Made of 10mm diameter steel bars welded at 200mm intervals. The total cross-sectional area of longitudinal reinforcement per meter is 393 mm². This is the highest strength, commonly used type.

a142 fabric mesh welded

Get the a142 mesh price

Selection comparison table

| Model | Approximate bar diameter/spacing | Strength Grade | Main Applications | Carrying capacity |

| A98 | 5mm, 200mm×200mm | Light Duty | Home floors, paths | ⭐ |

| A142 | 6mm, 200mm×200mm | Standard Duty | Industrial/commercial floors, slabs | ⭐⭐ |

| A193 | 7mm, 200mm×200mm | Medium Duty | Driveways, medium-duty floors | ⭐⭐⭐ |

| A252 | 8mm, 200mm×200mm | Heavy Duty | Warehouses, heavy-duty floors | ⭐⭐⭐⭐ |

| A393 | 10mm, 200mm×200mm | Extreme Heavy Duty | Ports, airports, power stations | ⭐⭐⭐⭐⭐ |

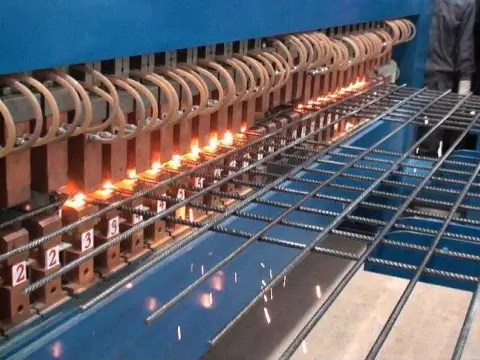

Production process

- Raw Material Preparation: High-quality low-carbon steel wire rod is cold-rolled into 6mm diameter ribbed bars.

- Straightening and Welding: After straightening, the longitudinal bars are resistance spot welded to the transverse bars at 200mm intervals.

- Cutting and Coiling: When the continuously produced mesh reaches the desired length, it is automatically cut by a flying shear. The mesh is then bundled or stacked into sheets based on rigidity.

- Inspection and Packaging: Online monitoring and offline spot checks ensure dimensional stability, strength, and weld quality. After the necessary anti-rust treatment, the mesh is strapped and labeled.

Welding according to dimensions

A142 GI Concrete Mesh for Sale

A142 Mesh Manufacturer & Supplier- Wanzhi Steel

Facing the challenges of cracking concrete floors and slow construction progress, choosing a globally proven material like A142 Mesh is undoubtedly the smartest decision. It’s more than just a rebar mesh; it’s the foundation for building a strong, durable project. Choose Wanzhi Steel and let us help you easily improve the quality of your project with our reliable products.

Why Choose Us?

- Production Scale: We have large production lines and strong production capacity, ensuring a stable supply and fast delivery for large orders.

- Technical Quality: We use advanced computer-controlled welding equipment to ensure uniform mesh and strong welds. We maintain comprehensive quality control and strictly adhere to domestic and international standards.

- Product Certification: We prioritize quality management. Factory direct pricing ensures competitive pricing in the steel market.

- Comprehensive Capabilities: We offer customized production capabilities for a variety of materials and special sizes. Leveraging our extensive industry experience, our products are widely used in numerous construction projects.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of deformed steel bar, Wire Mesh For Concrete Slab, Construction Binding Wire, Steel Reinforcement Mesh, Galvanized Concrete Mesh, A393 Mesh, GI Welded Wire Mesh, and A193 Mesh for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message