What Is Galvanized Wire?

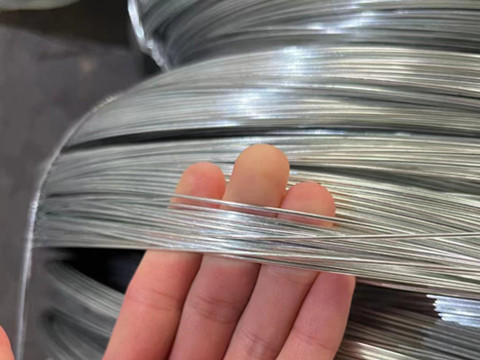

What is galvanized wire? Galvanized steel wire is a kind of versatile material that is coated with zinc to make it corrosion resistant. It is widely used for protection, binding, and supportive purposes, for example, fencing, packaging, etc. As a leading GI wire supplier, Wanzhi Steel offers a wide variety of GI wire for sale in different gauges.

Below let’s review the GI wire manufacturing process and its uses.

GI Wire

Galvanized Steel Wire

12 gauge hot dipped galvanized wire

Galvanized Wire Specifications

| Item | Galvanized Wire |

| Surface Treatment | Continuous hot-dip galvanizing, electro-galvanizing (cold galvanizing) |

| Type | Round wire, Flat wire, Oval Wire |

| Wire diameter | BWG8/10/12/14/16/etc, 0.6 mm- 6 mm, etc |

| Material | Low Carbon Steel Q195/Q235, SAE1006/SAE1008, ASTM A641/ASTM A228, etc |

| Tensile strength | 300-1500N/㎡ |

| Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

| Zinc coating | 10-240g/㎡ |

| Packaging | Spools, coils, reels, or as per customer requirements (Customized) |

| Applications | Wire mesh, springs, baling & tying, industrial cables, etc |

| Delivery | 10-15 days |

Galvanized wire weight calculation formula

Theoretically, its weight is calculated as follows:

Wire diameter²×0.00617×length=Weight

For a wire with a diameter of 3.658 mm, the weight per meter is approximately 0.08246 kg.

Continuous hot dip galvanized wire

Diameter measurement

Electro Galvanized Steel Wire

Advantages and characteristics of galvanized wire

1. Excellent anti-corrosion performance: The outermost galvanized layer effectively isolates the steel wire matrix from external oxygen, moisture, salt spray, etc., extending the service life.

2. Strong weather resistance: It can maintain stable performance under harsh conditions such as ocean and industrial pollution after long-term exposure to wind and sun.

3. High strength and toughness: The tensile strength and high ductility of 500-1500 MPa can meet various usage requirements such as bundling, weaving, tensioning, etc.

4. Processing adaptability: The thickness of the zinc layer is controllable, and the flexibility and wear resistance can be adjusted according to the application scenario. For example, cold-drawn galvanized wire is softer, and hot-dip galvanized wire is more wear-resistant.

5. Weldability: It can be galvanized and welded to form electric welded mesh for garden mesh rolls or building materials.

6. High cost performance: It has good economic efficiency due to its low maintenance cost and cheaper than stainless steel.

7. Customizable: 0.6mm-6mm diameter, zinc layer thickness, surface treatment (such as polishing, passivation, oiling), and packaging can all be flexibly selected.

Various forms of galvanized wire

1. Electro Galvanized Wire: thin zinc layer (5-20μm), low cost, but not suitable for outdoor humid environments. Smooth and beautiful surface.

2. Hot-dip galvanized wire: thick zinc layer (30-80μm), strong corrosion resistance, suitable for outdoor use.

3. Ordinary zinc layer galvanized wire: moderate zinc layer, high cost performance, the most choices.

4. High zinc layer galvanized wire: zinc layer ≥100μm, salt spray corrosion resistance, long life.

5. Galvanized round wire: round cross section, various specifications, good flexibility.

6. Galvanized oval wire: oval cross section, increased contact area, tighter weaving.

7. GI binding wire: flexible and easy to bend, commonly used hot-dip galvanizing process. Used for construction or object binding.

8. GI cable (rope) stranded: galvanized layer is rust-proof, the core is high carbon steel, and the load-bearing capacity is strong.

9. Galfan wire: a high-performance steel wire with corrosion resistance more than 3 times that of GI wire, which can be used for a long time in harsh environments.

GI Barbed Wire

Razor Wire

green pvc coated wire

Coated GI wire (PE/PVC coated): galvanized + plastic double layer protection, beautiful and weather-resistant.

Galvanized barbed wire: with sharp barbed wire, strong deterrence, usually hot-dip galvanized to prevent rust.

Galvanized razor wire: blade-shaped design, anti-climbing, galvanized + stainless steel optional.

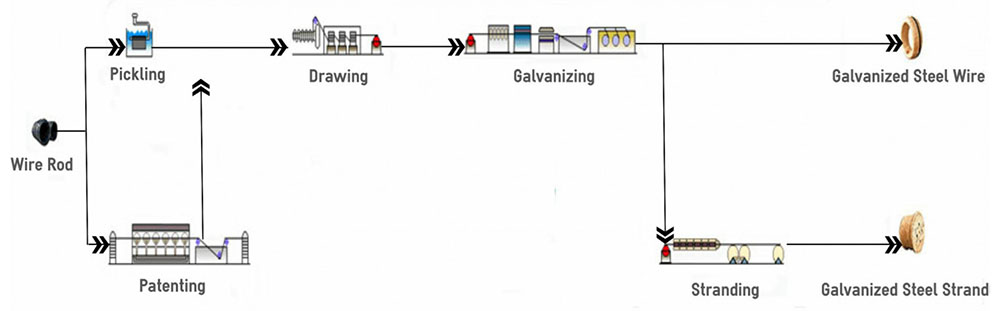

How Is Galvanized Steel Wire Made?

The GI wire manufacturing process is very simple. Here it is.

Wire Rods – Pickling (annealing – rust removing – acid washing) – Wire Drawing Process – Galvanizing Process – Stranding.

1. The first step is the pickling process, including annealing, rust removal, and acid washing, which aims to remove the impurities on the surface of wire rods.

2. Then it will go through the drawing machine, and steel wires will be formed into the desired size.

3. Then the wire will be galvanized by dipping into a zinc solution or electroplating.

4. This is the main difference between hot-dipped galvanized and electro-galvanized wires.

5. After galvanizing, the GI wires will be rolled into coils for sale.

GI Wire Manufacturing Process

What Is Galvanized Wire Used For?

Uses of various forms of galvanized wire

1. Cold-dip galvanized wire: hardware, small parts such as nails, screws, bolts and nuts, internal structural parts of electronic products, handicrafts, and decorations.

2. Hot-dip galvanized wire: building binding, concrete reinforcement fixing, making fences, fences, farm isolation nets, grape racks, vegetable support wires, and communication cable reinforcement cores.

3. Ordinary zinc-layer galvanized wire: general bundling, packaging, carton, hay packing, simple protective nets, chicken cage weaving. Temporary fixation in low-corrosion environment.

4. High zinc-layer galvanized wire: marine, such as docks, ship parts, coastal and tropical infrastructure. Chemical equipment protection net.

Barbed Wire Cattle Fence

coating pvc chicken wire for squirrel hen

GI concertina wire

5. Galvanized round wire: general-purpose iron wire, widely used for binding and weaving. Nail making, springs, and hardware processing. Thinner diameter (0.1-1mm) is used for electronics and precision devices.

6. GI oval wire: woven metal mesh, screen (such as mine screening), decorative grid, reinforcement material (such as composite board interlayer).

7. GI binding wire: fix concrete structure, support trees, vine traction, bundle wood, and pipes.

8. Galvanized aluminum alloy wire: raw material for fences in harsh environments (such as coastal areas and industrial areas). Replace traditional galvanized wire and extend service life.

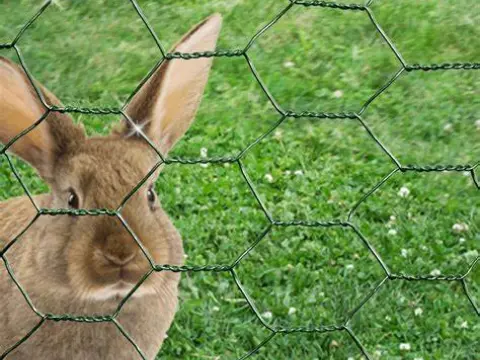

9. Coated GI wire (PE/PVC coated): decorative fences, garden fences (mostly green, black, and white). Animal cages (rust and scratch proof). Prison and military isolation nets (highly concealed)

10. GI barbed wire: top of fence, border isolation, perimeter protection of prisons and military restricted areas. Farm and warehouse anti-theft

11. Galvanized razor wire: nuclear power plant, airport fence, military defense, higher protection level than barbed wire.

Galvanized mesh after welding

Diamond Shaped Protective Mesh

Comparison of different diameters

Different Diameter Applications

0.3mm is suitable for flower wrapping, the axis of the cleaning ball.

0.4mm, 0.5mm, 0.6mm are suitable for crochet.

0.7mm, 0.8mm: DIY handicraft, shaped silk buttons, flower beads, and other crafts.

0.9mm-1.6mm is slightly hard and suitable for support.

Applications areas

1. Binding Materials

Because galvanized steel wire is strong and durable. It is often used as binding, baling, or earthing materials on construction sites. Due to its weather resistance, it is very popular among builders. You can also find GI wires used to make gabions.

2. Protective Fencing

Fence panels or walls made of high-strength galvanized wire can prevent thieves or animals from breaking in. Galvanized steel wire fences are often used in schools and gyms.

3. Making Handicrafts

The galvanizing process gives steel wire a bright and glossy surface. It can be made into household handicrafts such as bookshelves, vase holders, storage baskets, etc.

4. Agricultural Uses

GI wire is also widely used in orchards for supporting the growth of grapes or tomatoes and other vegetable farming. Due to the zinc coating, it can withstand the corrosion of pesticides and other chemicals.

5. Other Daily Uses

Galvanized wiring is also often used in packaging, animal cages, hanging pictures paintings, etc.

Gabions

Chain Link Fence

Binding Wire in Construction

Does Galvanized Wire Rust?

The answer is yes, but very slow. Any piece of steel product will oxidize and rust after exposure to rain or moisture. Rust damages the product itself and reduces its service life. However, after galvanizing, the zinc coating will enhance its corrosion resistance, which will protect it from rust. So GI wiring will rust very slowly, especially hot-dipped galvanized steel wires.

How is galvanized wire packaged?

There are generally four packaging methods:

1. Galvanized spool wire: Use reel packaging, which is suitable for wires with small wire diameters and no need for support.

2. Small roll packaging: also called beauty packaging, 1-2kg per roll, can be tied to the body when used, very portable.

3. Roll packaging: the most common packaging, lined with plastic film, woven bag, or lined with plastic film, or linen outside. This packaging can protect the binding wire from rusting, and is a good packaging to save packaging costs.

4. Large roll packaging: generally 500kg/roll, roll weight can be customized; this type of packaging is generally for customers to produce wire mesh.

Galvanized Spool Wire

Roll packaging Electro GI Iron Binding Wire

Small roll packaging Galvanized Wire Packaging

Galvanized wire price

0.3mm – 0.0098 USD/m

0.4mm – 0.007 USD/m

0.5mm – 0.0084 USD/m

0.6mm – 0.0238 USD/m

0.7mm – 0.014 USD/m

0.8mm – 0.0154 USD/m

0.9mm – 0.0154 USD/m

1.2mm – 0.0308 USD/m

1.6mm – 0.0476 US dollars/m

These prices are for reference only. The actual price depends on the zinc content, coil weight, packaging method, and order quantity.

Tips before buying

1. First, clarify the purpose and environment to determine the diameter and galvanizing layer. Choosing the right product will help save your maintenance costs. The most selected specifications are 8-16, and the commonly used galvanizing layer thickness is 10–240g/m2.

2. The order quantity determines the unit price of the product. Wanzhi Steel will provide substantial discounts for bulk orders.

3. Quality and service reliability are also crucial. Our multilingual team will save you a lot of time and money. If you need help, we will reply within 8 hours.

96 tons of galvanized wire shipped to Algeria

Galvanized Wire for Sale – Wanzhi Steel

You can buy at a lower price from China’s galvanized wire suppliers, such as Wanzhi Steel.

1. We provide hot-dip galvanizing/cold-dip galvanizing, PVC/vinyl/PE coating, and other surface treatments, such as 12-gauge GI binding wire is very popular.

2. There are double loop, single loop, straight cut, blade, barbed wire, and many other shapes, such as GI tying wire, double loop baling wire, concertina wire.

3. And provide welding, weaving processing services, such as galvanized chicken wire net, welded gabion, fence mesh.

4. You are welcome to visit the factory in person or via video.

GI wire Workshop

GI Wires for Sale

Galvanized wire for sale

So what is galvanized steel wire? How is it made? Where can I buy cheap galvanized steel wire? Where to wholesale galvanized steel wire? What is the price of galvanized steel wire? Now you have the answer.

Galvanized wire is widely used, easy to process, and very friendly to both users and investors.

If you are interested in galvanized wire, please contact Wanzhi Steel for details.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel Factory is an ISO 9001 certified enterprise located in Hebei, China. Specializing in the production of galvanized iron wire, Galfan Wire, Aluminium Wire, low carbon iron wire, PVC coated steel wire, cold drawn wire, Zinc Aluminum Alloy Wire, Baling Wire, and stainless steel wire, monthly output of 2000 tons, with high-quality products and good services. We have been exported to more than 120 countries around the world.

Leave Us A Message