Stainless Steel Mesh Screen

Stainless steel mesh screen is a high-quality mesh commonly used in petrochemical, food processing, papermaking, metallurgy, and mining industries. It has the advantages of being rust-resistant, fire-resistant, and corrosion-resistant. For example, 316 stainless steel and 304 stainless steel can provide food-grade safety. Its fine mesh allows airflow and light to pass through more easily. Wanzhi Steel specializes in the production of 200 series, 300 series, and 400 series stainless steel mesh. The wire diameter, mesh size, and mesh count can all be customized. Welcome to send size requirements.

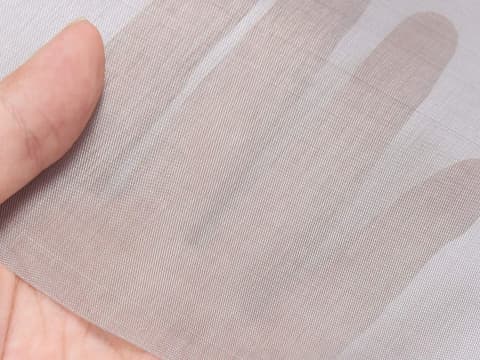

stainless steel screen

stainless steel fly screen

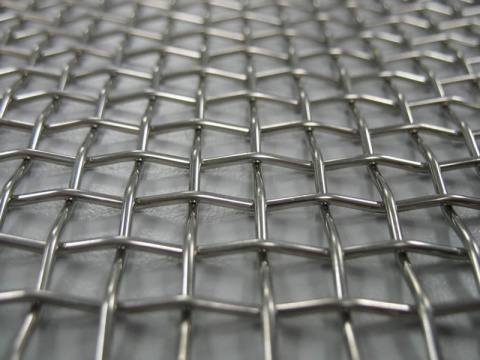

24 mesh stainless steel screen

Stainless Steel Mesh Screen Specification

| Item | Stainless Steel Mesh Screen |

| Project Solution Capability | 3D model design, graphic design, total solution for projects |

| Type | Weave/Welded Wire Mesh |

| Material | 200 series, 300 series(304, 304l, 316, 316l), 400 series(430) Stainless Steel |

| Application | Screen, Filters, sieving |

| Place of Origin | Hebei, China |

| Delivery Time | 8-14 days |

| Hole shape | Rould, square, hexagonal, length, scale, rectangle hole, etc |

| Surface treatment | Painted or oiled |

| Processing Service | Cutting, Punching |

| Width | 0.5 m-2.5 m, Customizable |

| Length | Customers’ Requirement |

| Certification | ISO9001:2019 |

| Mesh | 1-2000 mesh, 20/40/60 80/100/150/200/300/400 Micron |

| Wire diameter | Customizable |

| MOQ | 3 tons, 150 rolls |

| Payment Methods | TT, 30% prepayment, 70% before shipment |

| Transportation | Sea/land transport |

What is a stainless steel mesh screen?

It is a stainless steel mesh with regular mesh, fireproof, rustproof, and corrosion-resistant, while providing good visibility and ensuring air circulation. According to the different chemical element contents, it is divided into 304, 316, 430 grades, and others. There are welded or woven meshes with different meshes, such as Crimped Screen Mesh for Sieving, 40/60/80 mesh SS steel sieve, and 200/300/400 Micron Stainless Steel Filter Cloth. It is used in coal mining and, chemical industry.

Ss Steel Screen roll

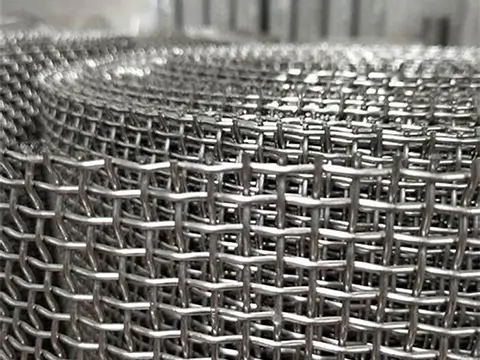

Stainless Steel Crimped Screen Mesh Sheet

Roll of Crimped wire mesh

Features

1. Corrosion resistance: resistant to acid, alkali, salt, and humid environment, long life, suitable for harsh scenes such as the chemical industry and the ocean.

2. Strong temperature resistance: can withstand ultra-low temperature to high temperature, up to 1200℃, stable structure at high temperature.

3. Strong and durable: non-magnetic in the annealed state. High strength, wear resistance, and can withstand high-pressure impact or coarse particle filtration.

4. Accurate filtration: pore size and wire diameter can be customized according to demand, with excellent flow rate. Can be perforated to form a stainless steel perforated plate.

5. Hygienic and easy to clean: food-grade materials are safe and non-toxic, with a smooth and easy-to-clean surface, and can be reused.

6. Beautiful and flexible: bright appearance, supports customized size, shape, and frame, and adapts to various needs.

7. Environmentally friendly and economical: 100% recyclable, low maintenance cost, more cost-effective for long-term use.

8. Typical uses: chemical filtration, food processing, medical disinfection, environmental protection treatment, home protection, and other high-demand scenes.

Sieves

Stainless Steel Sieve – Ø 40cm – Mesh 1 mm

Barbecue grill

Application fields of stainless steel mesh screen

1. Custom signs, Filters, Separators, and Ventilation grilles.

2. Insect repellent screens, Fountain covers, wye strainer screens, Stainless steel screen window, stainless steel mosquito net.

3. The column covers Stainless steel doors and windows.

4. Screens, lunch boxes, colanders, and metal screen mesh for the porch.

5. Custom lighting screens, speaker grilles Security screens.

7. Stainless steel wire mesh on walls or tenders to enhance security and prevent intrusion.

8. Stainless steel filter is used inside the machinery or outside the structure.

9. Handrail filler panels, Mining conveyor belts.

10. Food conveyor belt filtration.

11. DIY garden projects, baskets, trays.

12. Welded stainless steel wire mesh helps filter impurities in crude oil.

13. Stainless steel tea strainer, coffee filter.

14. Stainless Steel Filters, jet engine lubricating oil filters for high-pressure hydraulic filters.

15. A drainage pipe to protect the house from rain and fallen leaves.

steel mesh screens

304 stainless steel screen

y strainer screen

316 stainless steel mesh VS 304 stainless steel mesh

The chemical composition of stainless steel consists of two main elements: chromium and nickel. Depending on the grade of the material, these elements are adjusted to form a stronger or more magnetic metal.

Because of the increased nickel content and the addition of molybdenum in 316 stainless steel, it is 40% more expensive than 304 stainless steel mesh. However, it has stronger performance and is called “marine grade stainless steel”. The addition of the two elements enhances the corrosion resistance of the stainless steel itself in the chemical environment and also improves its strength under high temperature operation, which is also a prerequisite for the selection of materials in the food or marine industry.

304, 316, 316L stainless steel chemical composition by weight (%)

| AISI/SAE steel grades | Cr | Ni | C | Mn | Si | P | S | N | Mo | Others |

| 304 | 18-20 | 8-10.5 | <0.08 | <2 | <0.75 | <0.045 | <0.03 | <0.1 | ||

| 316 | 16-18 | 10-14 | <0.08 | <2 | <0.75 | <0.045 | <0.03 | <0.1 | 2-3 | |

| 316L | 16-18 | 10-14 | <0.03 | <2 | <0.75 | <0.045 | <0.03 |

304, 316, and 316L are also referred to as:

| Euronorm (EN) number | AISI/SAE steel grades | UNS | JIS | Also known as |

| 1.4301 | 304 | S30400 | SUS304 | SS304 | T-304 | A2 stainless steel | 18/8 stainless steel (18% chromium, 8% nickel) |

| 1.4401 | 316 | S31600 | SUS316 | SS316 | T-316 | marine grade stainless steel |

| 1.4404 | 316L | S31603 | SUS316L | SS316L | T-316L | A4 stainless steel | marine grade stainless steel |

heavy duty metal screen mesh

ss screen mesh

stainless steel fly screen mesh

Two basic types of stainless steel wire mesh

T-304

T-304 is a basic stainless steel alloy containing 18% chromium and 8% nickel. Less corrosion resistant than T-316, it melts at 2600 degrees Fahrenheit (1430 degrees Celsius) and is recommended for continuous service at 1450 degrees Fahrenheit (790 degrees Celsius) and for intermediate service at 1650 degrees Fahrenheit (900 degrees Celsius). T-304 stainless steel mesh uses include abrasives, liquid filtration, powder filtration, and sorting and screening of exotic solids.

T-316

T-316 is a special stainless steel alloy that contains 18% chromium and 10% nickel, as well as 2% molybdenum. This combination allows the mesh to resist corrosion from salt, acid, and seawater.

T-316 melts at 2500 degrees Fahrenheit (1375 degrees Celsius) and has a maximum recommended temperature of 1500 degrees Fahrenheit (815 degrees Celsius) for continuous use and 1650 degrees Fahrenheit (900 degrees Celsius) for intermediate use. Its uses include processing oils and foods, chemicals, and pharmaceuticals.

0.3mm – 15mm thickness Punched SS Perforated

2mm stainless steel welded mesh

316 stainless steel security mesh

Can stainless steel mesh screens be cut?

The right tools can cut stainless steel mesh to any desired size. In addition to cutting, welding is also possible.

For stainless steel wires from .001″ to .010″ in diameter, scissors can be used, and for thicker wires from .011 to about .047 in diameter, tin snips are needed. Wires larger than .047″ in diameter are difficult to cut with hand tools, but compound aircraft-style hand shears can usually accomplish the task.

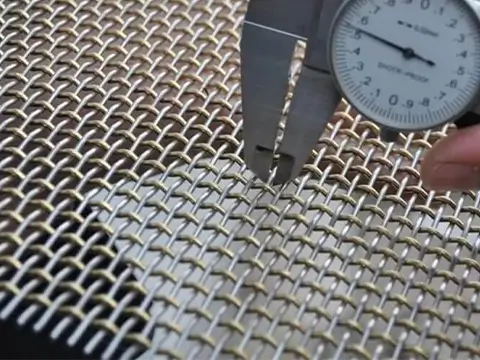

Mesh indicators: number of meshes, wire diameter, and aperture

1. Wire diameter: The thickness of a single wire.

2. Opening/aperture/hole size: The distance between two adjacent parallel wires

3. Mesh Count/Size: The number of openings/apertures/holes per inch of mesh. 1). Plain/Twill Weave: 2 – 635 Mesh. 2). Dutch Weave: 12X64 – 500X3200 Mesh.

4. Specify the mesh size in microns: Stainless steel filter 5 micron, 40 / 75 / 250 micron mesh screen, 70 micron stainless steel mesh, 300 micron stainless steel mesh filter.

Micron size usually refers to the nominal aperture size. For example, a 1 micron mesh means the mesh has a nominal aperture size of 0.001 mm. This is because 1 micron equals 0.001 mm.

Wanzhi Steel Quality Inspection

Woven mesh-diameter measurement

40 60 90 Salt Spray Tester

Tensile strength test

Packaging and Shipping

decorative metal screen mesh

stainless steel insect mesh shipped to slovenia

SS welded square mesh 304 to Mongolia

Stainless steel mesh screen for sale

✅ Advanced manufacturing capabilities: Equipped with automated production lines to ensure high-precision and high-efficiency production.

✅ Strict quality control: From raw materials to finished products, full-process testing is carried out to meet international standards.

✅ Rich experience: Focusing on the field of stainless steel wire mesh screens for many years, meeting the needs of multiple scenarios such as industry, construction, and screening.

✅ Customized services: Support flexible customization of specifications, materials (such as 304/316 stainless steel), and weaving processes

✅ Fast delivery: Large-scale factories guarantee stable supply, with a delivery cycle of 10-18 days.

Trust Wanzhi Steel, the quality is always consistent!

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001 certified steel mill located in Hebei Province, China. The company integrates production, manufacturing, and export, specializing in the production of Stainless Steel Mesh Screen, Insect screens for windows, Stainless Mesh Sheet, Perforated stainless steel sheet, SS welded wire mesh/Woven Wire Mesh, Fine mesh screen, Galvanized Wire Mesh Screen for 14 years with an annual output of 600,000 tons. With high-quality products and excellent services, our products have been put into use in more than 120 countries around the world.

Leave Us A Message