Stainless Steel Grating

Stainless steel grating is a grid-like structure made of stainless steel, consisting of bearing bars and cross bars connected by welding, press-locking, or other processes. No additional anti-corrosion treatment is required, but the surface is polished. Due to its corrosion resistance, high strength, aesthetic appeal, and ease of cleaning, it is widely used in industry, construction, and municipal administration. Wanzhi Steel is a professional grating manufacturer, offering stainless steel grating in a variety of grades, widths, and thicknesses. Custom shapes are also possible. Please feel free to contact us if you have any questions.

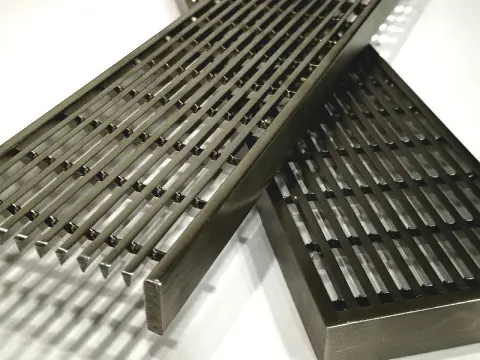

Outdoor 5mm thick SS heavy duty walkway trench cover

SS Steel Drain Grill Floor Grating

Specification

| Item | Stainless steel grating |

| Aliases | Stainless steel grille, Stainless sink grid, steel grates for drainage, stainless steel channel drain |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Surface Treatment | Spray-Painting, Polished, and Powder Coated |

| Bearing Bar Type | Flat Bar, Serrated Bar, I-Bar, Inserting Steel Grating, etc.. |

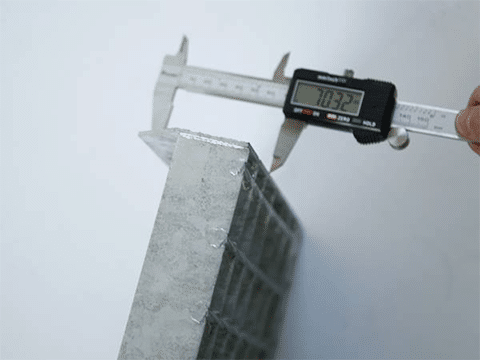

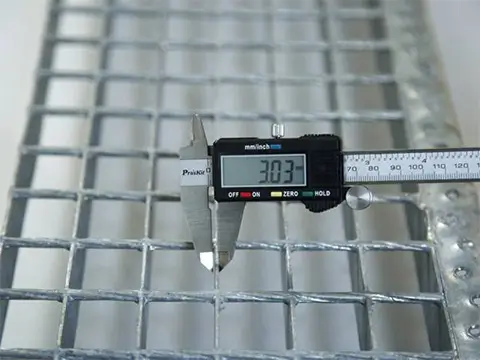

| Bearing Steel Thickness | 2.5mm, 3mm, 4mm, 5mm, etc |

| Bearing Steel Height | 25mm, 30mm, 40mm, 50mm, etc |

| Project Solution Capability | Graphic design, 3D model design, total solution |

| Width | ≥300mm, as your demand |

| Length | ≥600mm, as your demand |

| Application | Outdoor, floor, drainage system, walkway, horticulture, ditch cover, platform, ladder Treads, etc |

| Feature | Corrosion-resistant, non-slip, breathable and water-permeable, high strength and long service life |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

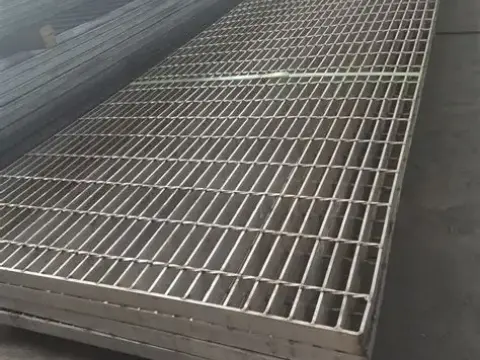

316 Metal Grill Stainless Steel Grates

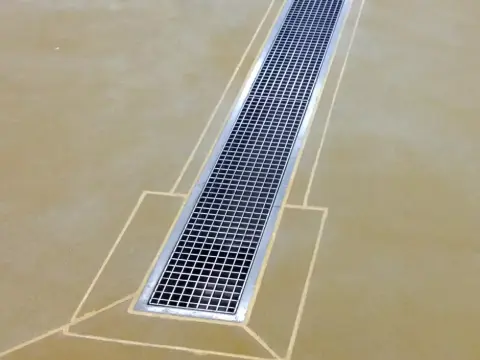

304 316 stainless steel floor drain Manufacturer

Main Features

Excellent Corrosion Resistance

The stainless steel surface naturally forms a protective layer, eliminating the need for galvanizing or painting. It’s naturally resistant to moisture, water, acidic and alkaline solutions, and salt. Its service life is significantly longer than that of ordinary steel grating.

High Strength and Reliable Load-Bearing

Its strong load-bearing capacity and stable structure make it suitable for high-load applications such as platforms, walkways, and stair treads. It can be processed with serrated or raised surfaces for non-slip safety.

Low Maintenance and Easy Cleaning

The smooth surface resists staining and can be cleaned with a simple rinse or wipe, eliminating the need for frequent repairs or replacements, resulting in low long-term operating costs.

Excellent Light Transmission, Ventilation, and Drainage

The grid structure allows light, air, rainwater, oil, and other pollutants to naturally flow through, penetrate, and drain, eliminating the need for additional drainage holes, commonly found in drain covers and vents.

Excellent Safety and Hygiene

This material and structure reduce bacterial growth, making it suitable for environments with high hygiene requirements, such as food processing and pharmaceuticals. Aesthetics and Adaptability

The surface can be matte or mirrored, adapting to various industrial and commercial environments (such as shopping mall ceilings and parking lot covers). Customizable size, grid spacing, and thickness offer exceptional versatility.

Stainless steel safety walkway grating

Bathroom floor drain for hotels

What are the common types?

(1) Welded Stainless Steel Grating

- Process: Flat steel (bearing bars) and cross bars are fixed by resistance welding or argon arc welding. The most commonly used type.

- Features: Strong structure, strong load-bearing capacity, suitable for heavy-load environments.

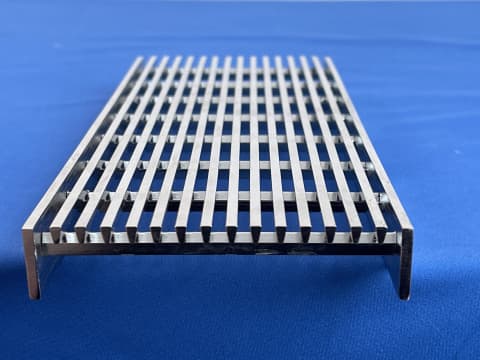

(2) Press-Locked Stainless Steel Grating

- Process: Flat steel is pre-grooved, cross bars are pressed in and mechanically locked, and no welding is required. Also called riveted stainless steel grating.

- Features: Higher surface flatness, no weld points, beautiful appearance, and better corrosion resistance, but the load-bearing capacity is slightly lower than the welded type.

(3) Swage-Locked Stainless Steel Grating

- Process: Flat steel and cross bars are fixed by splicing, usually used for special specifications or decorative purposes.

- Features: Flexible installation, can be customized for complex shapes, but the load-bearing capacity is lower.

Press-Locked Stainless Steel Grating

Swage-Locked Stainless Grating Platform

Welded stainless steel grille cover

Application

Industrial Applications

- Traffic and Load-bearing Components: Walkways/platforms for chemical plants and refineries; stair treads (for mines and machinery plants); covers for trenches/cable trenches.

- Special Applications: Suitable for explosion-proof and anti-static applications such as oil tank storage areas, fireworks and firecracker workshops, chemical warehouses, and underground coal mines.

Food and Pharmaceutical Applications

- Production-Related Applications: Workshop floors, operating tables, etc., non-toxic and easy to clean, disinfectable, resistant to detergent corrosion, and meeting hygiene standards.

- Sanitary Environments: Pharmaceutical sterile room work surfaces, food factory fermentation tank inspection corridors.

Building and Municipal Engineering

- Structural and Functional Support: This includes structural support components such as commercial building staircases and subway station passageways, as well as ventilation components such as data center cooling towers and green walls.

- Municipal and Decorative Applications: This includes road grates, manhole covers, and gutter covers. Municipal facilities such as pipe corridor escape covers, as well as architectural decorations, such as shopping mall ceilings and public toilet floors.

stainless sink grid

stainless steel channel drain

fountain stainless steel slot drain

Transportation and Shipping

- Marine and Offshore: Cruise ship decks, dock crane platforms, offshore platform helipads, etc.; dock walkways use 316 material for salt spray resistance.

- Rail Transit: Subway inspection panels, high-speed rail platform guardrails, tram platforms, and light rail bridge walkways.

Other Applications

- Marine and Outdoor: Landscape walkways, sewage treatment plant covers (corrosion-resistant, easy to maintain, and odor-resistant).

- Machinery and Equipment: Protective covers and ventilation structures (to protect equipment and promote heat dissipation).

Different types of corresponding applications

- Welded SS grating: Industrial platforms and walkways in chemical plants, power plants, docks, and sewage treatment plants, as well as municipal stormwater gratings.

- Compression-locked SS grating: Commercial buildings, municipal facilities, light walkways, food processing workshop floors, etc.

- Swage-Locked SS grating: Decorative railings, equipment maintenance platforms, temporary walkways, stair treads, and building curtain walls.

heel proof grating

For building exterior wall decoration

Food and drug workshop floor grilles

Core materials and properties

- 304 stainless steel: Excellent corrosion resistance, suitable for most industrial and residential environments; high strength, strong load-bearing capacity; smooth, easy-to-clean surface, meeting hygiene standards. Cost-effective, it is the mainstream choice in the market.

- 316/316L stainless steel: Enhanced resistance to pitting and crevice corrosion, resistant to seawater and chemical media; 316L has a lower carbon content, offering superior weldability. It has a long lifespan and is suitable for applications requiring extremely high corrosion resistance.

- 201 stainless steel: Less corrosion resistance, prone to rust; low cost, good workability. However, it is susceptible to corrosion with long-term use and requires regular replacement. Suitable for dry rooms and temporary facilities.

steel trench drain grates

Serrated stainless steel grille

Mechanical properties

- Tensile Strength: 304 stainless steel has a tensile strength of approximately 515-620 MPa, while 316/316L has a tensile strength of approximately 510-610 MPa.

- Yield Strength: 304 has a yield strength of ≥205 MPa, while 316/316L has a yield strength of ≥205 MPa.

- Elongation: ≥40%.

- Flexural Strength: 316 stainless steel has superior flexural strength to 304 stainless steel due to its molybdenum content.

- Compressive Strength: Compressive strength reaches 600 kPa (equivalent to 60 tons/square meter).

- Impact Toughness: Withstands moderate impact loads at room temperature. Stable performance in low-temperature environments (above -10°C).

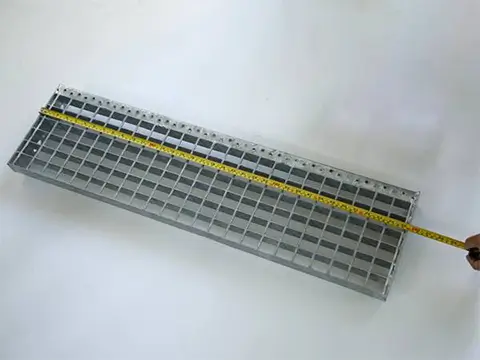

Steel Grating Length Inspection

Thickness test of steel grating plate

Thickness test of steel grating sheet

Installation and Maintenance

Installation

- Preparation: Clean the site, level the support frame (tolerance ≤ 3mm), and prepare stainless steel bolts, a spirit level, and welding wire of the same material.

- Laying and securing: Place the grille evenly and align it. Secure with bolts (≥4 points per piece, with rubber gaskets) for standard applications, and perform partial welding for heavy loads. Ensure uniform gaps between adjacent grilles (2-3mm is recommended).

- Inspection: Ensure there is no warping or looseness. Install guardrails on any exposed edges and clean any remaining installation debris.

Maintenance Guide

- Daily Maintenance: Rinse the grille surface with clean water to remove dust and debris. Oil stains can be removed with a neutral detergent. Avoid using strong acidic or alkaline cleaners (such as hydrochloric acid or caustic soda). Inspect the bolts and welds.

- Regular Maintenance: Every 3-6 months (1 month in a corrosive environment), thoroughly clean the crevices with a soft brush. Sand rust spots with fine sandpaper and apply anti-rust oil.

- Troubleshooting: Replace the grille partially or completely depending on the degree of deformation. Replace rusted bolts promptly. Repair welds on cracked welds.

1m x 1m outdoor stairway grating

Stainless steel grille welding

Stainless Steel Grating vs Galvanized Steel Grating

| Comparison Dimensions | Stainless Steel Grating | Galvanized Steel Grating (Carbon Steel Base + Hot-Dip Galvanizing) |

| Core Material | Austenitic (304/316/316L), inherently corrosion-resistant | Ordinary carbon steel (such as Q235) relies on the surface zinc coating for corrosion protection. |

| Corrosion Resistance | Strong, with a stable surface passivation film, 316/316L resists salt spray, strong acids and alkalis, and exhibits no rust even after long-term immersion. | Medium: The zinc layer blocks air and moisture, but the base will rust quickly if the coating is damaged (hot-dip galvanizing offers superior corrosion resistance to cold-dip galvanizing). |

| Mechanical Properties | Tensile strength: 510-620 MPa, yield strength ≥205 MPa, excellent low-temperature toughness, and no risk of coating detachment. | Tensile strength: 400-550 MPa, yield strength: ≥235 MPa. Slightly higher rigidity. Brittle at low temperatures. Wear of the coating does not affect the base’s mechanical properties. |

| Service Life | 15-30 years (316L can last over 30 years in corrosive environments). | 5-15 years (hot-dip galvanizing lasts approximately 10-15 years in dry environments, 5-8 years in humid/coastal environments). |

| Cost | High lifespan (2-4 times that of galvanized steel, with no additional corrosion protection costs). | Low (The cost of the base + hot-dip galvanizing is only 1/3-1/2 that of stainless steel). |

| Maintenance Requirements | Low maintenance: requires only regular water cleaning and no rust. | High: The zinc coating should be inspected every 1-2 years. Any damage or peeling should be reapplied with anti-rust paint. |

| Application Scenarios | Suitable for humid/corrosive environments (coastal, chemical, sewage treatment), food and pharmaceutical applications (meets hygiene standards), and high-end decoration. | Dry/slightly humid environments (general factory workshops, indoor platforms, municipal road decks, and outdoor areas in non-coastal areas). |

| Appearance and Cleaning | Glossy finish (can be brushed or mirrored), resists fouling, and easily restores gloss after cleaning. | Silver-gray surface: May oxidize and yellow over time, making cleaning relatively difficult. |

| Later-Term Potential Risks | No coating detachment; localized rust may occur only in extreme environments (such as strong chlorine corrosion). | If zinc coating damage is not promptly addressed, it can cause… “Galvanic corrosion” accelerates the rusting of the substrate, and it is necessary to focus on protecting the edges, welding points and other parts that are prone to wear. |

steel grating for sale

metal grating floor

Why Choose Wanzhi Steel?

- One-Stop Advantage: Wanzhi Steel boasts a complete industrial chain, from base material to finished product processing, including gratings, bolts, nuts, and screws.

- Advanced Manufacturing Process: Equipped with high-precision equipment such as laser cutting and CNC bending, we master the core processes of welding and press-locking gratings. Advanced surface treatment techniques ensure aesthetics.

- Strict Quality Control: ISO9001 certified, with comprehensive quality inspections and international certifications such as SGS. Multiple inspections are conducted from raw material receipt to finished product shipment.

- Customized Service Capabilities: We offer solutions for various scenarios, including architectural decoration and industrial platforms, supporting customized size and style. We have extensive experience in large-scale projects.

- Established Market Applications: Our products have been used in municipal and commercial applications in many countries around the world, receiving positive feedback and continuous orders. We offer highly competitive prices, including wholesale prices from the manufacturer.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei Province, China. For 14 years, we have been specializing in the production of stainless steel grating, Steel Grating Plate, aluminum bar, Galvanized Grating, aluminum expanded metal, Expanded Metal Grating, grating platform, serrated steel grating, sidewalk grating, and grating floor with a monthly output of 1800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message