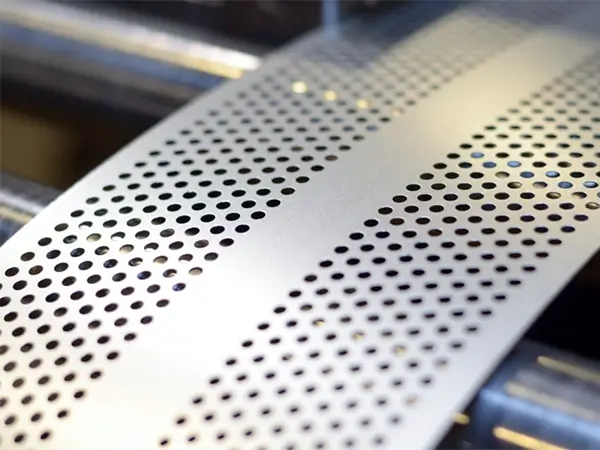

Perforated Stainless Steel Mesh

Perforated stainless steel mesh is a perforated metal sheet that combines the hardness of stainless steel with the filtering properties of perforated mesh. It can add strength and style to fences, partitions, signs, guards, and screens. It has the characteristics of ventilation, filtration, and a high strength-to-weight ratio. Stainless steel perforated mesh is one of Wanzhi Steel‘s hot-selling products. We offer perforated stainless mesh in 200 Series, 300 Series, and 400 Series. Customized hole types and sizes can meet the requirements of many aspects of your project. Welcome to contact us for more.

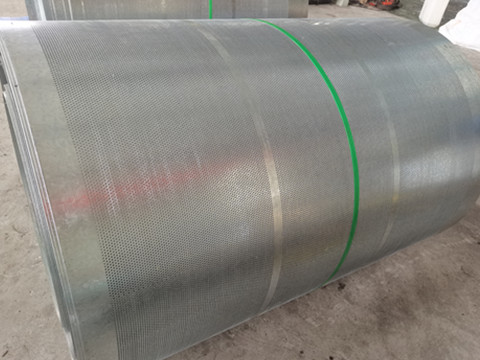

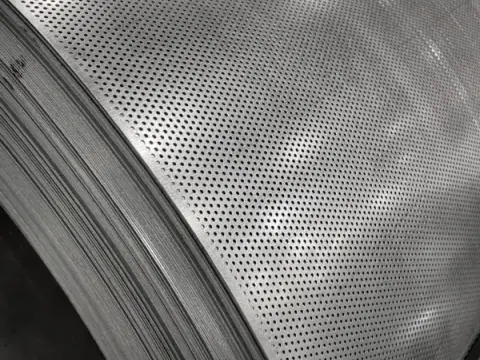

Perforated Metal Roll

430 304ss Metal Mesh Sheet package

Perforated Stainless Steel Mesh Specification

| Item | Perforated Stainless Steel Mesh |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Surface Finish | 2B/BA/Hairline/8K/NO.4/No.1 |

| Technique | Hot Rolled, cold rolled |

| Processing Service | Bending, Welding, Punching, Slitting, Cutting |

| Length | 100-6000mm or customized |

| Width | 100-2000mm or customized |

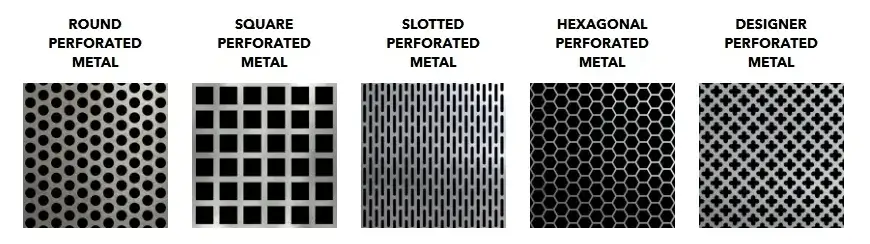

| Hole shape | Round, square, hexagonal, diamond, slotted hole, etc. |

| Hole size | 2mm-50mm |

| Shape | Flat Steel Plate, custom-made perforated filter tube |

| Function | Screening\separation\sorting\sieving\Grading |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons |

What is perforated stainless steel mesh?

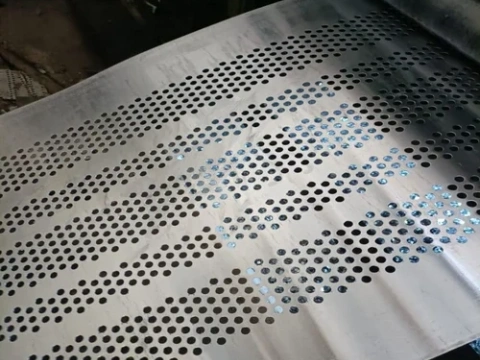

Perforated Stainless Steel Mesh, also known as stainless perforated sheet or stainless steel perforated metal, is a perforated metal sheet with regular holes punched out on metal sheets (except 304, 316, 430 stainless steel, aluminum, galvanized steel, aluminum-zinc coated steel, etc.) through precision stamping technology. The hole shapes include round, square, diamond, slotted, etc., which have the functionality and decorativeness of filtering, air permeability and light transmission while maintaining the complete structure. Its hole shape, hole spacing, plate thickness and roll width can be customized, and it is used in the fields of filtration, screening, and noise reduction, with outstanding corrosion resistance.

Production Video

Surface treatment

- 2B: The surface is matte silver-white, flat and smooth. It is the most commonly used basic surface obtained by annealing and pickling after cold rolling, suitable for further processing.

- BA: Bright annealing after cold rolling, the surface is as bright as a mirror but slightly inferior to the mirror, with high reflectivity, often used for decoration or scenes requiring high cleanliness.

- NO.1: The surface after heat treatment and pickling after hot rolling is dark silver-white, rough with traces of oxide scale, high strength, and mostly used in industrial load-bearing structures.

- NO.4: The surface is ground to form continuous fine stripes, with a hair-like matte, wear-resistant and easy to clean, commonly used in kitchen equipment and medical equipment.

- HL: The surface has continuous straight stripes (commonly known as “brushed”), the texture is coarser than NO.4, with both decorative and wear-resistant, widely used in home appliances and decoration fields.

- 6K: The mirror effect is inferior to 8K, the surface is bright but slightly contains fine textures, the reflectivity is moderate, the cost-effectiveness is high, and it is suitable for decoration scenes with slightly lower requirements for mirrors.

- 8K: After multiple grinding and polishing to a mirror effect, the surface is as bright as a mirror and has a very high reflectivity. It is mainly used for high-end decoration, mirror furniture, etc.

Different Hole Shapes

Classic punch shapes

Benefits of perforated stainless steel mesh

- Strong corrosion resistance: The dense oxide film formed by chromium elements can effectively resist the corrosion of chemical substances such as acid, alkali, and salt. 304 can withstand oxalic acid, sulfuric acid, and nitric acid, and 316 performs better in chloride ion environment.

- High strength and durability: It has high tensile strength, strong deformation resistance, wear resistance of 3-5 times that of ordinary sieve plates, and a service life of up to decades. The maintenance frequency is low, the replacement cycle is long, and the total cost is lower than that of ordinary materials.

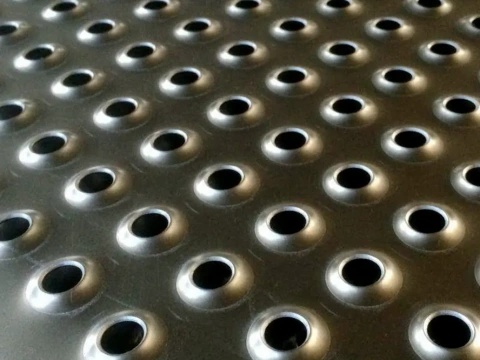

- Easy to process: It can punch out round holes, square holes, diamond holes, special-shaped holes, and other hole types, and can be processed into flat plates, arcs, and rolls. The aperture, hole spacing, and plate thickness can be adjusted as needed, and full-size customization is supported.

- Beautiful and practical: The surface is smooth and can be mirror-polished. The punching design can form geometric patterns and brand LOGOs. The hollow design reduces weight while maintaining structural strength. Through the optimization of aperture and arrangement, the dual effects of noise reduction and ventilation are achieved.

non-slip-perforated

Perforated Metal Sheets Manufacturer

304 stainless Long hole perforated sheet

- High safety: high density, stable structure, able to withstand external impacts such as vehicle collision and equipment vibration, melting point of about 1400℃, non-flammable, non-toxic, and will not release harmful gases in a fire.

- Easy maintenance: dust is not easy to accumulate on the surface, stains are resistant, and cleaning is convenient. The material can be recycled and reused. Lightweight design reduces transportation and installation costs. Aluminum plate perforated mesh combines the corrosion resistance of stainless steel with the lightweight of aluminum to further reduce costs.

Benefits of Perforated Plate Sieves

Compared with wire mesh sieve, perforated plate screen is more durable. It is made of a whole piece of metal plate, with a solid structure, strong impact resistance and tensile resistance, and can withstand high pressure and hard material impact, suitable for processing large particles and high hardness materials. The wire mesh sieve is woven with fine wires, and the nodes are easily damaged. When high-intensity operation or processing hard materials, it is easy to break, and the mesh is deformed, and the durability is relatively weak.

stainless steel fine mesh

0.3mm – 15mm thickness Punched SS Perforated

Applications

Industrial protection

Explosion-proof vents for tank trucks/chemical warehouses, industrial filters, sewage treatment grilles, protection and filtration for high-temperature environments (incinerator feed ports, sterilizer trays).

Environmental protection and energy

Noise barriers for highways and railways, ventilation nets for generator rooms/substations, heat dissipation structures for wind power sound insulation covers, perforated bases for solar brackets, and exhaust gas treatment filter plates.

Transportation

Ventilation nets/muffler linings for automobile fuel tanks, high-speed rail/aircraft vents, hull air intake hoods, subway platform shielding doors, and bridge and tunnel vents.

Home medical care

Household items such as kitchen steam racks/drain nets/oil fume filters, flower pot trays/lampshades, surgical instrument cleaning baskets, and hospital guardrails.

Artistic infrastructure

Art installations such as urban sculptures/stage background walls (light and shadow effects), and booth props (immersive experience).

Indoor ceiling

Perforated metal conveyor belt

Hospital Medical Waste Fence

304 vs. 316 Stainless Steel Perforated Sheet Mesh

Material properties

| Features | 304 stainless steel | 316 stainless steel |

| Composition | 18% chromium, 8% nickel | 16% chromium, 10% nickel, 2% molybdenum |

| Corrosion resistance | Resistant to general acid and alkali, a humid environment | Stronger, resistant to seawater and chloride ion corrosion |

| Cost | Low | Higher (molybdenum content) |

| Applicable environment | Indoor, general industry | Coastal, chemical, high saline, and alkaline environments |

Performance Differences

- 316 perforated SS sheet: Molybdenum significantly improves the ability to resist pitting corrosion, suitable for harsh environments such as ships, coastal buildings, medical, and food industries.

- 304 perforated SS sheet: High cost performance, widely used in interior decoration, screens, and mechanical equipment protection.

Perforated corrugated board

Stainless Steel Perforated Sheet Hexagonal hole

Service life

The service life of stainless steel perforated plates is related to the material, environment and maintenance. In dry indoor places, the service life of 304 stainless steel perforated plates is 20-30 years, while 316 stainless steel is longer; in coastal areas and chemical areas, 316 stainless steel perforated plates are recommended, with a service life of 10-20 years; and in wear scenarios, such as screening equipment, its service life is 8-15 years.

Perforated Stainless Sheet Mesh vs. Perforated Aluminum Sheet Mesh

- Stainless steel metal mesh is known for its high strength, durability, and corrosion resistance. It is also heat and fire resistant, making it ideal for high temperature applications. Stainless steel is often preferred over aluminum in applications where high strength and durability are required.

- Perforated aluminum metal mesh is a lightweight, strong, and durable material, although not as strong as stainless steel. Aluminum is commonly used in marine and outdoor applications and has a strong corrosion resistance. It is a more popular choice than stainless steel for projects where weight and cost are important considerations.

Perforated aluminum sheet

perforated stainless steel mesh

How is Perforated stainless steel mesh made?

- Material selection: 304 stainless steel is selected for general industrial and civil scenes, and 316 stainless steel is selected for chemical coastal scenes.

- Plate thickness: Select thickness according to purpose, 0.8mm-2mm for architectural decorative net, 3mm-6mm for mechanical protective net.

- Mold design: High-precision CNC mold processing equipment is used to achieve aperture error ≤±0.1mm, hole spacing error ≤±0.15mm, and support more than 20 hole types such as round holes, square holes, and diamond holes.

- CNC stamping: Using CNC punching machine, stepper motor feeding, and PLC control system to achieve accurate stamping of plates, and gradient hole design can be performed.

hexagonal perforated SS steel sheet

Custom sizes

- Surface treatment: There may be tiny scratches on the surface of the plate after stamping, and the appearance is improved by polishing or wire drawing.

- Cutting and trimming: According to the needs, the whole roll of plate is cut into specified sizes, and the excess edge material is removed by laser cutting or shearing machine.

- Leveling: Use a leveling machine to level the deformed plate after stamping to restore the original flatness.

- Cleaning: Remove lubricant residues through the degreasing process to ensure that the surface cleanliness meets food grade or medical grade standards.

- Powder coating: Optional, using epoxy resin or polyester powder, customizable color and enhanced weather resistance.

- Quality control: Real-time monitoring of hole diameter and hole spacing, dimensional tolerance, salt spray test, tensile test, board width, board length, board thickness and other tests through laser sensors.

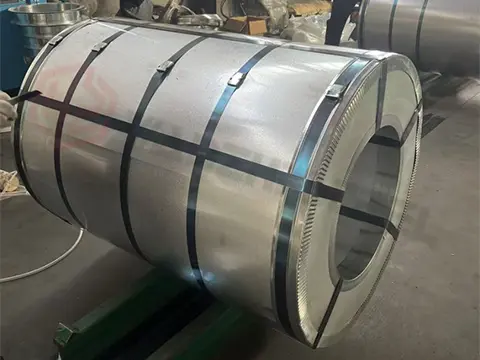

- Packaging and transportation: Wrapped with moisture-proof paper + fixed with wooden pallets to ensure no deformation during long-distance transportation, the maximum weight of a single roll can reach 2 tons.

Perforation production line

Please enjoy our production video of galvanized perforated sheet and aluminum perforated sheet.

SS 304 Perforated Sheet Weight Chart

| Product(s) | Alloy | Weight Each(#) | Thickness(T) | Hole Size(T) | Test | Length(L) | Hole Pattern | Hole Center |

| 304 Perforated Stainless Sheet | 304 | 48.38 | 16 ga | 3/8″ | 48″ | 96″ | Staggered | 9/16″ |

| 39.51 | 16 ga | 3/4″ | 1″ | |||||

| 29.03 | 20 ga | 1/8″ | 3/16″ | |||||

| 28.07 | 20 ga | 1/4″ | 3/8″ |

Things to note when buying Perforated stainless steel mesh

When you choose perforated metal panels for your application, a few factors must be considered.

1. Material: Select the material according to the purpose and requirements. We provide 302, 304, 304L, 316, 316L, and other stainless steel series.

2. Thickness: We provide 0.2-10mm stainless steel sheets, which can be customized according to the application and provide cutting.

3. Hole type: The hole diameter and shape are very important. Our experts advise the punching/stamping thickness to be larger than the sheet thickness in order to attain maximum benefit. The pattern selected must also be checked for the correct pitch in order to avoid dimensional inaccuracy and errors.

4. Overall tolerances: Specified tolerances on the product dimensions help us to produce the perfect product for your application.

Package

Stainless steel perforated mesh coil package

1mm2mm SS perfotated plate outer package

Perforated stainless steel mesh manufacturer-Wanzhi Steel

Get perforated stainless steel mesh price from us

Wanzhi Steel has various grades of stainless steel perforated mesh, and provides other materials including aluminum, carbon steel, galvanized steel, Galvalume steel, tin tin-plated steel. In addition, we have all hole types of molds to produce various patterns, and provide 2B/BA/HAIRLINE/8K/NO.4/No.1 surface treatment and all machining services.

If you are looking for durable and almost maintenance-free perforated mesh, then perforated stainless steel plate is your best choice.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Stainless steel perforated sheet, Perforated Steel Mesh, MS Perforated Sheet, and Perforated aluminum sheets, Galvanized expanded metal lath for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message

- Perforated Aluminum Sheet Mesh

- Perforated Steel Mesh

- Stainless steel perforated sheet

- Mild Steel Perforated Sheet

- Galvanized Hardware Cloth

- Galvanized expanded metal lath

- Expanded Metal Grating

- Diamond Mesh Lath

- Galvanized Square Mesh

- Welded Wire Fabric

- Galvanised Welded Mesh Panel

- 430 Stainless Steel

- 304 Stainless Steel