GI Wire Uses, Price, Features – The Most Complete Guide

What is GI Wire, what is Tie wire, and what is the relationship between GI Wire, Baling Wire, and Cut Wire?

First of all, they are all made of galvanized wire. The following content has everything you want to know about GI wire. So, please continue reading. Welcome to Ask For An Online Quote! (Chat on WhatsApp / Email Directly).

1. What is GI wire?

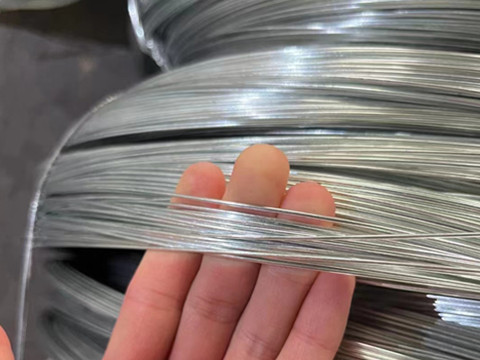

GI wire, also known as galvanized iron wire, is a type of wire made by coating a carbon steel wire with zinc. The zinc coating acts as a barrier to protect the steel wire from rust and corrosion. The process of applying the zinc coating is called galvanization, which is why it is called galvanized iron wire.

Electro Galvanized Steel Wire

GI wire supplier

2. Is GI wire a material?

Yes, Galvanized iron wire is a versatile material that has many uses. It is made of steel that has been coated with zinc, which protects it from rust and corrosion. Thus, this makes GI wire ideal for a variety of applications, both indoors and outdoors.

3. What is another name for GI wire?

Galvanized wire. GI wires or galvanized wires are nothing but simply iron wires that have been strengthened by the chemical process of galvanization. Galvanization is a process that involves coating the steel wire with a protective, rust-resistant metal, like Zinc and zinc Aluminum.

4. What is GI tie wire used for?

GI tie wire, also known as Galvanized binding Wire, is mainly used for bundling and fixing, and weaving crafts, and fences. Because it is galvanized, it can resist erosion by moisture, oxidation, and other factors. Because of its strong processability, it is easy to cut, bend, and weld. Therefore, it can be used for bundling steel bars, tying hay, supporting garden plants, fixing cables, and pipes, weaving baskets, fences, etc.

Reinforcement Binding Wire

Hay Binding

Galvanized Baling Wire for Sale

5. Will GI wire rust?

Galvanized wire typically holds up for a long time before it begins to rust—often decades. The material could last much longer if used indoors or in a relatively dry outdoor environment with moderate temperatures.

6. What is the quality of GI wire?

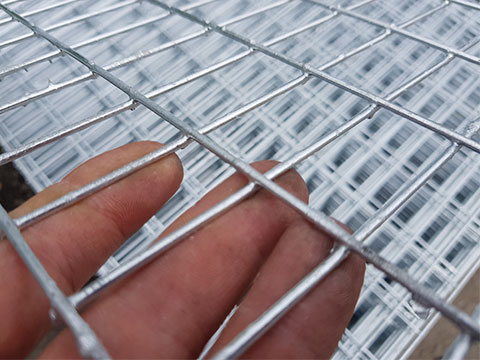

Its quality is better than ordinary iron wire, and it is durable, has superior physical properties, and is easy to process. Therefore, many finished products are made of galvanized wire, such as GI Farm Fences, garden fences, hog panels, welded wire mesh, mesh screens, mesh cloth, Chain Link Fences, etc.

WANT A QUOTE?

![]() WhatsApp CHAT DIRECTLY / EMAIL DIRECTLY

WhatsApp CHAT DIRECTLY / EMAIL DIRECTLY

7. Is the GI wire magnetic?

Galvanized iron wire is made of low-carbon steel, which is an iron-carbon alloy and has a certain degree of magnetism. Therefore, in terms of material, GI wire is magnetic without special treatment.

Even if galvanizing has little effect on the magnetism of iron wire, the magnetism of iron wire will be reduced after annealing.

Therefore, whether GI wire is magnetic or not depends on its base material, that is, the iron wire before galvanizing.

galvanized tubing wire

Stainless Tubing Baling Wire

8. Galvanizes Wire VS Stainless Steel Wire

| Galvanized Wire |

VS |

Stainless Steel Wire |

| Made of carbon steel wire rod, with a layer of zinc plated on the surface |

Materials and ingredients |

An alloy is mainly composed of elements such as iron, chromium, and nickel, and partially contains elements such as molybdenum. |

| 1. It can prevent rust to a certain extent. If it is exposed to harsh environments (such as high humidity and salinity) for a long time, the zinc layer will be damaged.

2. The durability is relatively good, but not as good as stainless steel wire. |

Corrosion Resistance And Durability | 1. Excellent corrosion resistance and durability, able to maintain stable performance in a variety of harsh environments

2. Performs well in high-corrosion environments such as marine and chemical industries |

| 1. Good toughness and elasticity

2. Depends on the properties of the base material (low-carbon steel) |

Physical Properties |

1. With high strength and hardness

2. Some ss steel wires have good high-temperature resistance and are suitable for high-temperature environment applications |

| 1. Construction, agriculture, handicrafts, wire mesh, and others

2. Used to make fences, scaffolding, grids, packaging belts, etc. |

Application Areas |

1. Food processing, medical equipment, chemical equipment, aerospace.

2. Decorative elements, precision instrument parts, etc. |

| The cost is lower and the price is more affordable. |

Price And Cost |

The cost is high and the price is relatively expensive. |

So if you have a sufficient budget, stainless steel is recommended, as it is an indispensable material in high-end applications. But if your use environment is not particularly harsh, galvanized steel is sufficient.

9. What is the difference between GI wire Rope and steel wire Rope?

GI wire Rope, the main body is a steel cable, but a layer of zinc is covered on its surface. Steel wire Rope is made of multiple strands of steel wire ropes twisted around a fiber core or steel wire rope core without additional surface treatment (such as galvanizing).

| GI Wire Rope |

VS |

Steel Wire Rope |

| 1. Effectively prevent steel cables from rusting and corroding in humid and corrosive environments

2. Suitable for highly corrosive areas such as oceans and chemical industries |

Corrosion Resistance And Durability | 1. Poor corrosion resistance

2. In humid or corrosive environments, steel cables are prone to rust and corrosion |

| Silvery white or silvery gray | Appearance And Color | Original metal color, usually dark gray or black, may have rust on the surface |

| 1. Marine engineering, bridge construction, chemical equipment, and other fields.

2. Outdoor slings, lifting equipment, and other scenes that need to withstand large tension and harsh environments |

Application Areas | 1. Construction sites, mines, ports, etc.

2. Heavy lifting, traction, and tensioning operations. |

| 1. The cost may be slightly higher because it requires galvanizing.

2. In the long run, it can reduce maintenance and replacement costs. |

Cost And Maintenance |

1. Relatively low cost

2. Frequent maintenance and replacement are required, and long-term costs increase |

Galvanized wire rope

Steel Wire Rope

Galvanized Wire Rope IWRC FC

10. How do you remove rust from GI wire?

Generally speaking, rust removal requires the following simple steps:

1. Use a soft cloth or sponge to remove dust and dirt on the wire.

2. Soak and apply with white vinegar or lemon and salt.

3. You can also spray with rust remover.

4. Gently scrub and wipe with a soft cloth or brush.

5. Gently rinse with clean water and dry the GI wire.

6. To maintain the GI wire, you can apply anti-rust paint or oil.

11. What is the difference between MS wire and GI wire?

MS refers to low-carbon steel (carbon content less than 0.25%), while MS Wire refers to ungalvanized Low Carbon Steel Wire, its corrosion resistance and durability are not as good as GI wire. The main difference between the two is that one is galvanized and the other is not.

12. Why is GI wire used for earthing?

What is GI earthing? GI earthing uses mild steel pipes with Galvanized Iron coating to complete the earthing system. Steel is also a very good conductor of electricity and allows any dangerous electricity to flow to the ground, taking the danger away from you.

13. What is the lifespan of GI wire?

With a lifespan upwards of 50 years, galvanized wire costs less than other wire products and lasts longer than them too. What’s more, on top of having a really long lifespan, those who choose galvanized wire will also realize it’s very low maintenance due to its strong protective outer layer.

gi chain link fence

GI Razor Constantine wire

Galvanized Fence Panels

14. How to prevent GI wire from rusting?

1. Keep the environment dry.

2. If the environment is not ideal, check the surface of the GI wire in time.

3. Avoid friction with sharp objects.

4. Use vinegar or weak acidic substances to remove rust in time.

5. Apply zinc-rich paint or anti-rust coating on the surface.

6. Clean the gap garbage in time.

7. Prevent accumulation and high-intensity pulling.

8. Do not contact with other metals directly or for a long time.

15. What is the strength of GI wire?

The tensile strength of the gi wire when tested in accordance with IS: 1821/1972 shall be between 450.550N/mm2.

16. What is GI wire used for?

Usually, we use GI wire to bundle hay, weave gabions, climb support for vines, fix steel bars on construction sites, etc. Its uses are similar to those of tie wire mentioned at the beginning of the article.

However, the scope of GI wire is broader. It not only refers to the binding wire but also includes Straight Cut Wire, Steel Wire Rod, Zinc Aluminum Alloy Wire, Baling Wire, Construction Binding Wire, Black Annealed Wire, Steel Reinforcement Bar, etc.

For example, Galvanized Razor Wire, Barbed Wire, and coated Galvanized Wire are all reprocessed galvanized wire. They are used for isolation protection on fences, production of chain link fences, Screens, hardware cloth, etc.

17. What is the thickness of GI wire?

Standard GI wire is available in standard sizes like 2.5 mm gi wire, 3mm gi sheet, 4 mm GI wire, and different gi wire gauges like 6 swg gi wire, 8 swg gi wire, gi wire 10 gauge, gi wire 10 swg, gi wire 12 gauge. Wanzhi Steel produces galvanized wire of all specifications.

Galvanized Farm Fencing

Garden Wire Mesh

Galvanized Welded Wire Fabric

18. Is galvanized wire waterproof?

Galvanized wire itself is not waterproof, its main function is to prevent corrosion and rust. Whether it is hot-dip galvanized wire or cold-dip galvanized wire ( Electro galvanized wire ), the zinc layer is mainly used to improve the corrosion resistance and rust resistance of the wire, thereby extending its service life.

You can refer to this article – Hot Dipped VS Electro Galvanized Wire.

However, the galvanized layer cannot prevent the penetration of moisture, because the galvanized layer is not completely impermeable. Therefore, galvanized wire is not the best choice on occasions where waterproof performance is required. On the contrary, if the waterproof function is required, materials with a waterproof coating or special structure are usually selected, such as waterproof fabric, waterproof tape, waterproof coating, etc.

19. What kills rust on galvanized metal?

There are several main methods of rust removal, each with its own advantages and disadvantages, and they need to be selected based on the degree of corrosion of the galvanized wire.

1. Mechanical removal: Use tools such as wire brushes, sandpaper, and grinding wheels to remove rust by physical friction. However, the zinc layer may be damaged.

2. Chemical cleaning: Use acid or alkaline detergents to react with rust to dissolve or convert it into substances that are easy to remove. Note that the detergent concentration should not be too high. After cleaning, rinse with clean water and dry.

3. Electrolytic rust removal: Apply current to the surface of galvanized metal to make the rust react with the electrode and fall off.

4. Anti-rust treatment: Apply anti-rust paint and anti-rust oil. Form a protective film to isolate air and moisture, thereby preventing the base metal from further corrosion.

20. Can GI wire be welded?

It is possible to weld galvanized wire. However, attention should be paid to welding methods, welding parameters, pre-welding treatment, and post-welding treatment. Since zinc evaporation and spatter may occur during welding, this may affect the quality and appearance of the welded joint. Therefore, corresponding measures need to be taken during the welding process to reduce zinc evaporation and spatter, such as using low-spatter welding materials, adjusting welding parameters, etc.

21. What is the resistance of the GI wire?

The tensile strength of the GI wire when tested in accordance with IS: 1821/1972 shall be between 450.550N/mm2.

Wanzhi Steel Fence workshop

Woven Wire Mesh

PVC Coated Hexagonal Wire Mesh

23. How is GI wire made?

Galvanized wire (GI wire) is made of low-carbon steel wire, and is processed through drawing, pickling and rust removal, high-temperature annealing, hot-dip galvanizing, cooling, and other process flows. The production process is a complex and delicate process.

Different manufacturers have different production standards. It is recommended to choose a regular factory. Don’t blindly pursue low prices. Quality is the most important.

For example, China’s Wanzhi Steel is a professional manufacturer of galvanized wire, exported to India, UAE, Philippines, Zimbabwe, Singapore, Africa, Pakistan, Indonesia, and dozens of other countries.

Production includes GI wire, GI barbed wire, Galvanized Razor Wire, Steel Reinforcement Bar, Galvanized Concrete Mesh, PVC GI wire, and chain link fence. So it is worth your cooperation.

24. How to calculate GI wire weight?

These elements will have a direct bearing on your calculation. The formula is quite simple. You have to multiply the thickness in mm by the width and then by the value 7.87, which is the density of steel galvanized with zinc.

25. What is GI tie wire?

Galvanized tying wire is a type of wire used for tying and fixing construction materials. It is made of steel wire that has been coated with a layer of zinc to protect it from rust and corrosion.

Rebar Tie Wire

U – Tie Wire

Binding Wire in Construction

26. Can I use galvanized wire for concrete?

Galvanized reinforcement is ideally suited for use in all types of thin and lightweight concrete construction.

27. Is galvanized wire good for outdoor use?

Galvanized wire mesh can be used for many outdoor residential projects. These include fencing and enclosures, compost bins, pest control, gutter guards, chicken coops, tree guards, cloches and cages, trellises, garden arches, and gabions.

28. Which is stronger, stainless steel or galvanized?

When compared at similar thicknesses and forms, stainless steel is always stronger than galvanized steel. An effective way to compare this is by looking at the tensile strength of each material. Tensile strength is the resistance of a material to breaking under tension. Exact figures will vary by the alloy in use.

Packaged chain link fence

Wanzhi steel

Steel Reinforcement Rebar Mesh

29. The end

That’s all for now. If there’s anything else I haven’t mentioned, please Leave A Message or Contact Me. I am Joy from Wanzhi Steel. I hope this article is helpful to you. Therefore, if you have any intention to buy, you are welcome to Chat With Me. I am waiting for you 24 hours a day. And I wish you a happy day!

Lastly, for the latest price, special Requests ( packaging method, color, etc). Welcome to contact!

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel Factory is an ISO 9001 certified enterprise located in Hebei, China. Specializing in the production of galvanized iron wire, Q195/Q235 low carbon steel wire, PVC coated steel wire, and stainless steel wire, monthly output 2000 tons, with high-quality products and good services, the products have been exported to more than 120 countries around the world.

Leave Us A Message