Galvanized VS Annealed Wire

Galvanized wire is often compared with annealed wire. This is because they both have similar uses, such as being used as Binding wire. In fact, each type of wire has unique characteristics and properties. Galvanized wire and annealed wire differ in many ways, such as treatment, flexibility, production process, and color appearance. If you are interested, keep reading to learn more details about both of them.

Galvanized Wire Introduction

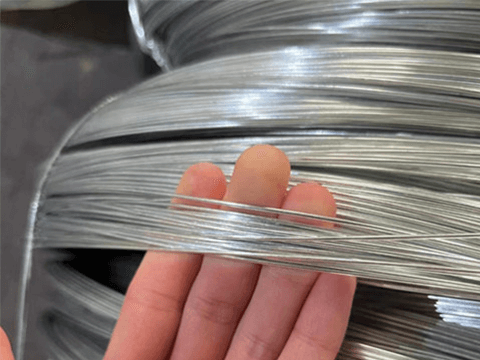

Galvanized wire, as the name implies, is a wire coated with a zinc layer. Due to the zinc coating, the wire becomes more durable. This is because the zinc layer has the effect of preventing rust and corrosion.

There are two types of galvanizing processes, hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thicker zinc layer, up to 300 microns. Electro-galvanizing, on the other hand, has a thinner zinc layer, usually only 3-15 microns.

This means that wire that has undergone the hot-dip galvanizing process has better corrosion protection than wire that has undergone the electro-galvanizing process.

You can learn the detailed difference between the two through this article – Hot Dipped VS Electro Galvanized Wire.

Galvanized Wire

GI Steel Wire in Wanzhi Factory

GI Binding Wire for Sale

Galvanized Steel Wire Applications

Due to its excellent performance, galvanized wire is widely used in various fields such as construction, handicrafts, highway guardrails, product packaging, and daily civilian use. In addition, it can also be made into wire mesh for use. Take the garden fences, animal fences, and meadow fences that we commonly see in our daily lives as examples, many of them are made of galvanized wire.

Pros

Robust and durable;

Long service life.

Annealing Wire Introduction

Annealed wire is a soft iron wire product made from low carbon steel by cold-drawing, heating, constant temperature, and heat preservation processes. It has a tensile strength of 300 ~ 500 MPa. In addition, due to its unique manufacturing process, annealed wire has flexibility that other metal wires do not have. It is very flexible and can be used for various purposes.

Annealed Wire Applications

Because of its flexibility and plasticity, black annealed wire is widely used in construction, handicrafts, woven wire ropes, filters, and other fields. Among them, 1.6mm wire is processed by machine to beat the spool, mainly in the special wire for haying machine. It is popular to use annealed wire for baling hay.

Annealed Wire

Black Annealed Wire

Annealed Binding Wire

Differences Between Galvanized and Annealed Wire

Here are the differences between the two for your reference.

| Galvanized wire | Annealed wire | |

| Definition | Low carbon steel wire with galvanized surface | Iron wire was heated to a certain temperature and slowly cooled |

| Material | High quality carbon steel | High quality iron wire |

| Process | Drawing and forming → pickling and rust removal → high temperature annealing → hot dip galvanizing → cooling | Pickling→Descaling→Drawing→High temperature annealing |

| Characteristics | Corrosion resistant, durable, relatively poor flexibility | Soft and flexible, poor corrosion resistance, smooth surface |

| Application | Wire mesh fence, wire mesh, tying steel bars, fixed mesh panels, vineyard trellises, plant supports, fish cages, buoys | Bundling rebar, tying materials, crafts and DIY projects, mesh and netting, grounding wire |

Comparison of Corrosion Resistance

Although annealed wire is equally resistant to rust when oiled, galvanized wire is still better than annealed wire in terms of corrosion and rust resistance. When black annealed wire is used or stored outdoors, it can easily rust, which can cause the wire to fail. Galvanized wire, on the other hand, is well adapted to the outdoor environment. It still performs well even under harsh conditions.

hot dipped galvanized wire

Cold rolled spring wire

Black Annealed Twisted Wire

Flexibility Comparison

From the perspective of flexibility, galvanized wire is not as tough as black annealed wire. In the production process, the quality of the finished wire is ensured so that the wire reaches a certain level of strength and the appropriate level of flexibility. This also means that it will be more flexible to use.

The following table summarizes the performance of the two.

| Specification Comparison | Galvanized wire | Annealed wire |

| Coating | Galvanized to prevent corrosion | Uncoated; prone to rust |

| Flexibility | Harder and harder to bend | Soft, easy to bend |

| Durability | Highly durable and long-lasting | Less durable in wet environments |

| Surface Finish | Rougher due to galvanizing | Smooth and soft |

| Cost | More expensive due to galvanizing | Cheaper |

| Applications | Outdoor, fencing, construction | Bookbinding, crafts, electrical |

Fixed garden trellis

Binding Wire in Construction

PVC coated galvanised barbedwire fence

Which One Is Right for Me?

Galvanized wire or annealed wire, which is better for you? You need to determine your use.

Choose galvanized wire if:

You need corrosion resistance (e.g. outdoor or marine applications).

Durability and strength are important.

Choose annealed wire if:

You need flexibility and ease of use (e.g. bundling or stapling).

For use indoors or in dry environments.

There is no one better than the other, it mainly depends on your application. If you don’t know which one to choose, you can seek help from professional technicians, we will provide guiding suggestions upon request.

Galvanized Wire for Sale

Black Annealed Wire Wholesale

U-shaped binding wire paper box package

Leading Wire Manufacturer – Wanzhi Steel

Wanzhi Steel is a reputable manufacturer of metal wire in China. We can provide you with high quality galvanized and annealed wires. In addition, you can also find PVC coated wires, Zinc Aluminum Alloy Wire, and Stainless Steel Wire from us.

We will provide you with a wide range of steel wires in various sizes. With rich export experience and have sent to more than 120 countries including Barbados, Samoa, Croatia, France, Germany, Kazakhstan, Brazil, India, Iran, etc.

If you have plans to buy, our friendly technicians are always ready to give you a quote.

Please don’t hesitate to Get In Touch With Us.

( Inquire Online or send an email to Info03@wanzhisteel.com.)

Leave Us A Message