How Is Barbed Wire Made?

Barbed wire is a security fence with excellent safety features. And it is tough in itself, simple and easy to install, and does not require frequent maintenance. Therefore, it is often used for community fences, highway fences, government agencies, borderlines, and other places where high security performance is required. Since barbed wire is so popular, do you know how it is made? Next, Wanzhi Steel will tell you the answer.

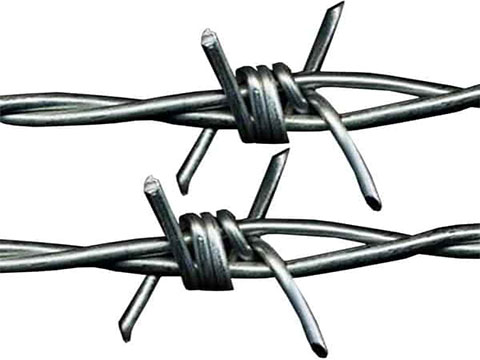

Barbed Wire

Galvanized Barbed Wire

Manufacturing Process

There are many processes to go through before you get the finished barbed wire. Read on to learn more.

Manufacture of Steel Ingots

How are steel ingots made? First, iron ore, coke, and limestone are heated in a blast furnace. At this point, the coke produces heat and carbon monoxide. The carbon monoxide reacts with the iron oxides in the ore, releasing the iron. The limestone, in turn, reacts with the impurities in the iron ore. Eventually, pig iron is forged.

It is important to notice that if you want to convert pig iron into steel, you must remove impurities and most of the carbon. This is because if the carbon content of iron is too high, it will become brittle. However, if the carbon content is too low, the iron will be much weaker than steel.

Making the Billets

Before making the barbed wire, there is one more step that needs to be performed, and that is making the billets. First, the ingot is heated to about 1200°C. Then, it is placed between slotted rolls and rolled back and forth until it reaches the proper size. The billet is then cut to the desired length using shear and allowed to cool. Next, the billet is heated again and rolled again. This is done until it becomes a round bar. This wire is then coiled into a coil and is ready for the next steps.

Before the process of manufacturing barbed wire, there are still the following preparations to be made.

1. Removal of Iron Oxide

The iron oxide formed during the healing process of the steel must be removed. Otherwise, the wire can easily rust. This can be done by pickling. In addition to this, it can also be removed by spraying it off with fast-moving sand, aluminum oxide, or cast-iron projectiles.

2. Drawing of the Wire

The wire is drawn through a die until the desired diameter is determined. Barbed wire, typically has a diameter of 2.5 mm. This usually requires about six or seven dies to achieve this size.

3. Annealing

To make the wire flexible, it needs to be annealed. How is annealing done? It is done by heating in a molten salt bath, a molten lead bath, or a furnace containing nitrogen.

Barbed Wire Production

Now, it comes to the part of barbed wire making. After the previous series of processes, the whole process of making the next will be much easier.

1. First, the wire needs to be galvanized. Galvanization will provide a protective layer. The zinc layer will make it less prone to rust and corrosion. Keep in mind, however, that the wire must be completely clean and dry to be properly galvanized. Otherwise, an uneven zinc coating will occur.

2. Next, the galvanized wire is fed into the machine. In the process, it can be twisted and woven into single and double strands. It will then be wound on a shaft and cut to the proper length.

3. Finally, the barbed wire is made. After quality inspection, it will be packed and shipped to customers.

Finished Product

Barbed Wire for Sale

Conclusion

In fact, Wanzhi Steel has been in the wire mesh industry for more than a decade. We not only provide barbed wire but also equally sharp razor wire. If you are looking for high quality, long-lasting barbed wire, then buying from Wanzhi Steel is the best choice. Our products are tried and tested, and only at a decent price. Get in touch with us now for more details!