Galvanized Square Mesh

Hole Shape: Square/ Rectangular

Wire Diameter: 0.45-6 mm

Delivery Time: 15-21 Days

Transportation: By sea, by land

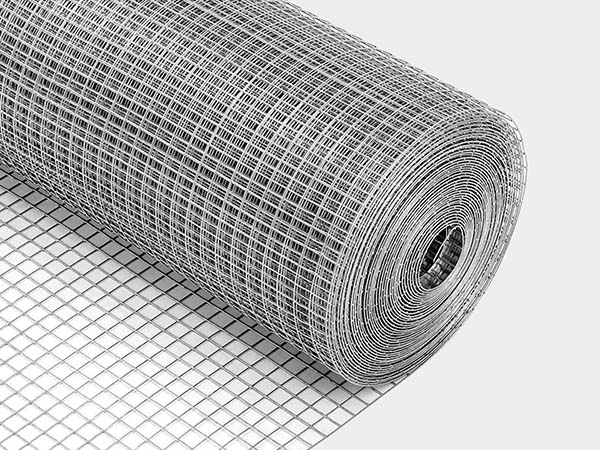

Galvanized Square Mesh

Galvanized square mesh is corrosion-resistant, durable, breathable, and light-permeable, and attractively priced. It meets a variety of application needs, such as fencing, mechanical guards, filtration systems, animal cages, filling panels, etc. Wanzhi Steel offers a variety of apertures, wire diameters, and mesh sizes. Whether you need light or heavy-duty wire mesh, including woven mesh, welded mesh, or punched square mesh, we can meet your needs. Customized services are also accepted. If you are interested, please contact us for more information.

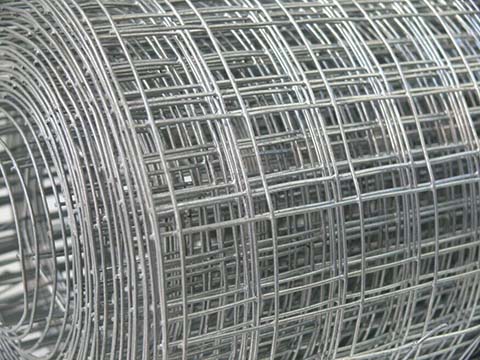

Welded Square Mesh

Woven Square Mesh

Specifications

| Item | Galvanized Square Mesh |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Surface Treatment | Electric galvanized, hot dipped galvanized, PVC coated |

| Steel Grade | Q195/Q235/SAE1006/SAE1008 |

| Color | Silver |

| Opening Size | 1/4” – 8” |

| Roll Length | 25-50 m or As per your requirements |

| Applications | Fencing, Animal cages, GI Mesh Screen, Filter, etc. |

| Sample | Free Available |

| Payment Term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons, 220 rolls |

Benefits of Galvanized Square Mesh

- Strong rust resistance: Through hot-dip galvanizing or electro-galvanizing process, the zinc layer formed on the surface of the wire can prevent the wire mesh from oxidation and corrosion, and prolong its service life.

- Strong and stable: Made of high-strength low-carbon steel wire, it has high tensile strength and impact resistance. The mesh structure is uniform and can withstand greater pressure and tension.

- Uniform mesh: The hole size is consistent and regular, which is convenient for standardized production and application. It can be customized according to needs and used in screening or filtering occasions.

- Easy to install: The galvanized square mesh is light in weight and easy to transport. It is flexible and can be cut according to needs, suitable for various installation environments.

- Beautiful and practical: The mesh surface is smooth and flat, the appearance is neat and tidy, and it has a certain decorative effect. It can be used for industrial protection, building fences, agricultural breeding, and garden landscaping.

- Economical: It is cheaper than stainless steel mesh or Galvan mesh, and has a high cost performance. Low maintenance cost. Bulk purchases enjoy discounts.

stainless welded wire mesh roll

galvanized woven wire fence

Uses

1. Construction and Engineering: Safety nets, fences, isolation nets for construction sites. Reinforcement materials in concrete structures. Building exterior wall decoration, sunshade nets, ventilation nets, etc.

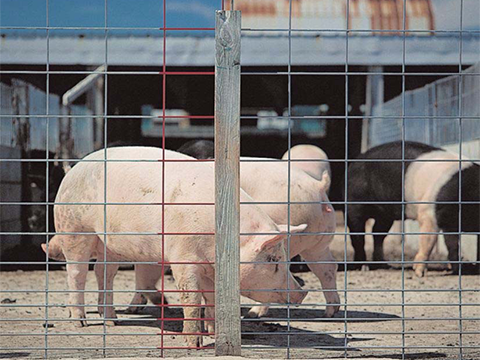

2. Agricultural field: fences for farms and pastures, sunshade nets and windbreak nets for greenhouses, used for screening and filtering of grain and feed, and for grain storage and stacking.

3. Industrial field: In the chemical, petroleum, and food industries, it is used for filtering and separating liquids and gases. It is used for screening and grading of ore, coal, sand and gravel. It is used for protective nets around mechanical equipment.

4. Home & Gardening: It is used for gardens, courtyards, poultry, and small animal fences, and also as plant climbing frames, DIY projects. Or bird nets and insect nets.

5. Transportation: It is used for protective nets on highways, railways, and suburban roads to transport fixed goods.

6. Environmental Protection and Water Treatment: It is used for filter nets in sewage treatment plants to remove solid impurities. It is used as a protective net in landfills to prevent the spread of garbage.

7. Sports facilities: used for fences in stadiums, courts, playgrounds, racecourses, fencing events, etc. to ensure the safety of spectators and athletes. Used for exhibition stands and display nets, etc.

hog wire

Temporary fence fixing

square welded wire mesh

Types of Galvanized Square Mesh

According to its galvanizing method, it can be divided into hot-dipped galvanized or electro-galvanized wire mesh. While in terms of the processing technique, you can find welded and woven square meshes on the market. Below is a table for your reference.

| Welded | Woven |

| Electro-galvanized before welding | Electro-galvanized before weaving |

| Hot-dip galvanized before welding | Hot-dip galvanized before weaving |

| Electro-galvanized after welding | Electro-galvanized after weaving |

| Hot-dip galvanized after welding | Hot-dip galvanized after weaving |

window screening mesh

field fencing

Which One Is Better?

By comparison, the welded mesh has a stronger structure than the woven one. Also, the weaving process of woven wire is mostly automated, while the welding process is a lot more hands-on. So, Welded Mesh is more costly.

Besides, the hot-dipped galvanized wire mesh is more corrosion-resistant than the electro-galvanized one. Actually, the wires used in galvanized before welding or weaving (GBW) meshes are galvanized wires. Generally, it will cost less for customers.

But by the GAW (galvanized after welding or weaving) process, the entire mesh is immersed in zinc solution or electro-galvanized so that the entire mesh is coated with a protective layer.

This process is more costly, but the product is better resistant to corrosion. You can choose according to the use environment and your budget.

welded wire mesh

galvanized wire mesh

Commonly used wire gauge comparison table

| Wire Gauge (SWG/BWG) | Wire diameter (mm) | Common mesh sizes (mm) |

| 22 Gauge (SWG) | 0.71 | 6×6, 10×10 |

| 20 Gauge (SWG) | 0.91 | 12×12, 15×15 |

| 18 Gauge (SWG) | 1.22 | 25×25, 30×30 |

| 16 Gauge (SWG) | 1.63 | 50×50, 75×75 |

| 14 Gauge (SWG) | 2.03 | 100×100, 150×150 |

Note:

- 20/22 gauge is used for light duty or animal cages and building protection. 14/16/18 gauge is suitable for heavy duty, industrial and mechanical use.

- SWG (British Standard Wire Gauge) vs BWG (Birmingham Wire Gauge) are slightly different (e.g. 18 gauge SWG=1.22mm, BWG=1.24mm).

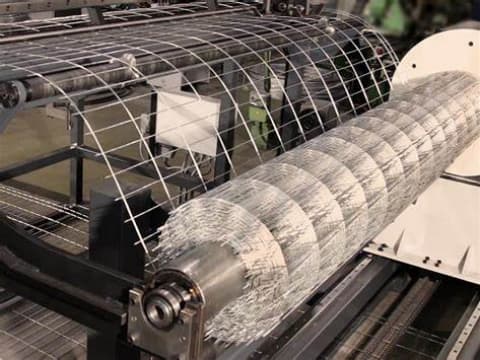

Production process

- Material preparation: Select standard low-carbon steel wire or carbon steel plate raw materials to ensure that they meet production requirements.

- Galvanizing: The iron wire or steel plate is galvanized on its surface through hot-dip galvanizing or electrogalvanizing.

- Weaving process: For flexible materials such as galvanized iron wire, a square mesh material is made by the plain or twill weaving process. The plain weave mesh surface is smoother, and the twill weave can improve the stability of the structure.

- Welding process: The galvanized wire is vertically cross-welded to ensure that the welds are uniform and burr-free, without leaking or bubbling.

- Punching process: For rigid materials such as galvanized steel plates, advanced CNC punching machines are used to accurately punch holes according to the designed pattern and aperture to form the required mesh structure.

- Surface treatment: The processed mesh is cleaned, degreased, passivated, etc., to further improve the corrosion resistance and aesthetics of the product.

- Finished product inspection: Strict quality inspection is carried out on the produced galvanized square hole mesh, including size measurement, hole type inspection, flatness test, galvanized layer adhesion test, etc.

Metal Wire Rod Wanzhi facroty

Stainless steel wire production line

square welded wire mesh

How to Choose A Suitable Mesh?

The application will determine how to choose a suitable mesh. You need to take the wire diameter, opening size, galvanizing method, and processing technique into consideration.

- Welded mesh is sturdy and durable, so it will be a good fit for heavy-duty uses, such as cattle fencing. But if for filtration purposes or pest control, a fine mesh opening will be better.

- Hot-dipped wire mesh is suitable for corrosive conditions as it has a thick zinc protective coating; But if for temporary uses, the cold galvanized mesh will be more affordable.

- If mesh strength is not what you concerned about, and you’re looking for a cost-effective mesh, woven wire mesh is right for you.

Packaging

Galvanized wire mesh products are often packaged into rolls or panels. Generally, the roll length is 5 to 50 meters. And then they will be wrapped with waterproof paper inside and plastic film outside. In order to fix them during transportation, we also package the coils with wooden pallets. Moreover, if you have special requirements, please let us know.

Galvanized Farm Fence Shipped to Fiji

16 gauge GI welded wire mesh shipped to Türkiye

GI square wire mesh for sale – Wanzhi Steel

As a professional wire mesh manufacturer, Wanzhi Steel has the industry-leading galvanized square mesh production capacity:

- Fully automatic production line: equipped with high-speed precision weaving machines, mature galvanizing process.

- Strict quality inspection: zinc layer thickness gauge + salt spray test machine double detection, in line with ISO, ASTM and other international standards.

- Customized service: supports 0.45-6.0mm wire diameter customization, and can produce all sizes of mesh.

- Global project experience: annual export volume exceeds 5 million square meters, successfully applied to benchmark projects such as Libya Redemption Hospital facilities and Dubai Solar Farm.

Let Wanzhi Steel become your most reliable galvanized square mesh supplier!

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized wire mesh, rebar/concrete mesh, Garden wire mesh, GI square mesh, and GI Wire Mesh Roll for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message