Galvanized Grating

Bearing bar shape: Rectangular Bar

Sizes(Width x Length): 36″ x 240″; 36″ x 288″ (Custom sizes Available)

Flat Steel Shape: Flat row, toothed, I-shaped

Manufacturing Process: Welded, swage-locked, or press-locked

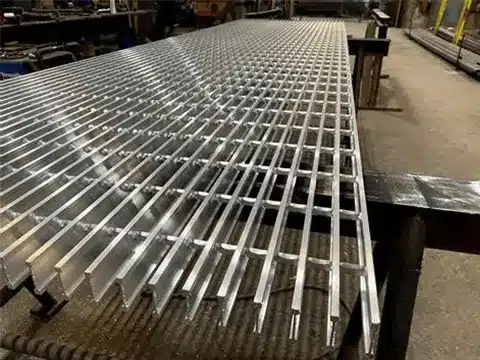

Galvanized Grating

Galvanized grating is a galvanized steel grating product. Galvanizing can significantly improve the corrosion resistance of steel gratings, thereby extending their service life. It has the characteristics of high strength, high load-bearing capacity, and anti-skid. It is suitable for various heavy-load situations and has a variety of specifications and models. At Wanzhi Steel, sizes and models are all accepted. We have our own independent factory that has been established for 13 years, so we will provide ex-factory prices for bulk orders, we have exported to dozens of countries, have cooperated with thousands of successful cases, and have a good reputation Reputation guaranteed, you are welcome to contact me for an online quote!

Toothed Steel Grating

steel grating

Galvanized Grating Specifications

| Item | Galvanized Grating |

| Material | Galvanized Steel |

| Bearing bar shape | Rectangular Bar |

| Product Form | Panel |

| Sizes (Width x Length) | 36″ x 240″; 36″ x 288″ (Custom sizes Available) |

| Material Finish | Mill Finish |

| Flat Steel Shape | Flat row, toothed, I-shaped |

| Sample | Avaliable |

| Delivery time | 7-15Days |

| Manufacturing Process | Welded, swage-locked, or press-locked |

| Installation Method | Welding, clips, or bolts and nuts, depending on the application |

| MOQ | 5 Tons |

expanded metal grating

galvanized steel grating

What Is Galvanized Grating?

Galvanized steel grating, also known as galvanized steel grating, is an open galvanized steel component with a square grid in the middle, which is made of flat steel and cross bars arranged at a certain interval and welded. It is also called grid plate, grid trench cover, etc. Due to the galvanizing treatment, its chemical and physical properties are stable and it is not easily oxidized by air and corroded by microorganisms. It can also withstand large loads. It is mainly used for walkways, stairs, trench covers, railings, etc.

Production Video

Key Features Of Galvanized Grating

1. High strength and durability: After welding and pressing, it has a high load-bearing capacity.

2. Lightweight and easy to install: Compared with traditional concrete, it is light and simple.

3. Anti-slip: The special surface structure reduces the risk of slipping.

4. Ventilation and light transmission: The open structure helps to maintain air circulation and light penetration.

5. Easy to maintain and clean: The structure is simple, dust and debris are not easy to accumulate, and daily maintenance is also convenient.

6. Diversified designs and applications: It can be customized according to customer requirements, including size, shape, thickness, process, packaging

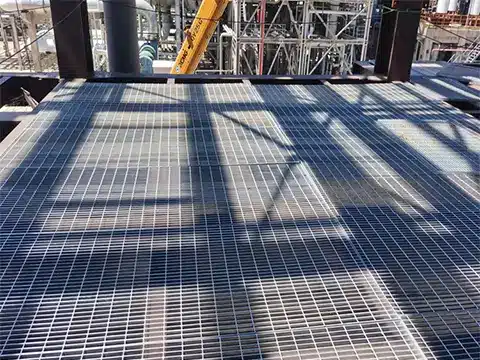

Platform walkway grille

Metal Bar Grate for Walkway

What types of steel grating are there?

In addition to Galvanized grating, there are many other types, which I summarize as follows:

1. Angle steel grating plate: Made of steel wire or angle steel, it has the advantages of corrosion resistance, impact resistance, and high strength. It is suitable for large buildings such as ships, trains, and airports, and can withstand greater pressure and weight.

2. Paving board: It is laid on the road surface and has the functions of shear resistance, anti-skid and anti-fouling. It is often used in places such as roads and parking lots where anti-skid and load-bearing capacity are required.

3. flat grating: It is generally a steel grating plate arranged in parallel, with a stable structure and strong load-bearing capacity. It is mostly used in the power, petroleum, and chemical industries as the ground for platforms, walkways, etc.

4. Guard steel plate and flat angle grating plate: It is used for the protection of bridges, road bridges, etc., and has good load-bearing and protective performance. It plays an important role in infrastructure such as bridges and roads,

5. Special-shaped grating plate: The shape and size can be customized according to specific needs, and it has greater flexibility. It is mainly used in special occasions such as power plants, granaries, and machinery and equipment.

galvanized catwalk grating

bar grating

Grooved grating drain cover

6. Steel safety net: It is used to protect the connection parts between high-rise buildings, overpasses, etc. to prevent sudden crashes of machinery and equipment, and has good protective performance. Ensure the safety of personnel and equipment in the fields of construction, industrial installation, etc.

7. Screen and shade window mesh: Screen nets are used for the fences of outdoor platforms, which have the function of sound insulation and heat insulation. Shade nets are used for the fences of indoor stairs to prevent children from falling down the stairs, etc. They are mostly used in residential and public places.

Types of Galvanized Steel Grating

1. Hot-dip Galvanized Steel Grating

Hot-dip galvanizing is to put the metal structure into the galvanizing tank, and the zinc liquid in the zinc tank is evenly attached to the surface of the grid. The characteristics of this process are strong anti-corrosion ability, good zinc layer adhesion and high hardness.

2. Press-locked Galvanized steel grating

Press-locked Galvanized steel grating is made of low carbon steel and stainless steel. It is a grid formed by welding or press-locking cross bars to bearing bars. The press-locked grating has the characteristics of high strength, light structure, high bearing capacity, anti-corrosion, and so on. Used in power plants, chemical plants, refineries, steel mills, machinery plants.

3. Welded Galvanized steel grating

Made of low-carbon steel or stainless steel, it is widely used in construction, petroleum, chemical industry, sewage treatment plants and other industries. The surface of welded galvanized steel grating is hot-dip galvanized or electro-galvanized, which has good corrosion resistance and rust resistance.Welded Galvanized steel grating is divided into two kinds of bearing bars: flat bar and I-bar. The distance between the two bearing bars is called pitch or pitch.

expanded steel grating

Steel Grating for Construction Site

galvanized walkway grating

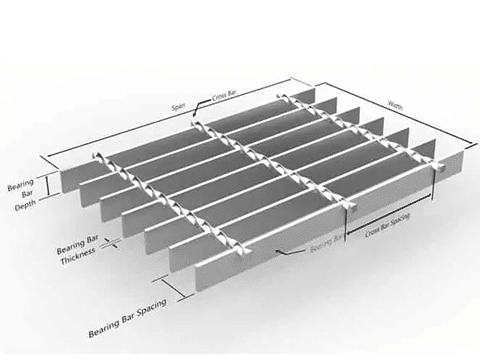

Sizes and models of Galvanized grating

The galvanized grating has various specifications and models to meet different occasions. The following are some common specifications and models:

| Specifications and models of Galvanized grating | |

| Bearing Bar Specifications | 20×3-100×10 (mm), and I-section types such as 25x5x3, 32x5x3, etc. |

| Load-bearing bar spacing(Pitch) | Common ones are 12.5, 15, 25, 30, 40, 50, 60, 80, 100mm, etc., among which 30, 40, and 60mm are more commonly used. |

| Cross Bar Spacing | Common ones are 38, 50, 76, 100, 101.6mm, etc., among which 50 and 100mm are more recommended. |

| Material | Galvanized Carbon Steel |

Why Choose Wanzhi Steel Galvanized Steel Grating?

Galvanized steel grating is an ideal choice for a variety of applications. It is durable, versatile and strong. If you are looking for reliable and strong materials for your project, please consider Wanzhi Steel’s galvanized steel grating. You won’t be disappointed!

1. Durability: We have strict quality inspections in every process to ensure that the galvanized steel gratings we produce meet international standards, are durable, and minimize your maintenance costs.

Steel Grating Parameters

2. Customization: We accept customization of various specifications such as product surface treatment, size, packaging, shape, delivery, etc. We will meet all your requirements.

3. Timely delivery: Our factory is 1,000+ square meters, and there are dozens of machines in the steel grating workshop, and there is a large amount of spot inventory. Even for bulk orders, they can be delivered within 15-20 days, so that you can see the goods you purchased as soon as possible.

4. Good service: Not only pre-sales service, if you have any questions or questions after receiving the goods, please feel free to contact us, and we will provide one-on-one guidance.

Grating Grids for Drain Cover

Steel Grating Plate Heavy Duty

Wanzhi Steel Pre-purchase Tips

1. Application: Consider whether the metal grille will be used indoors or outdoors, the load, span, and support requirements, as well as the capacity for pedestrians, carts, and cars.

2. Product Spacing: The measurement from the center of one bearing rod to the center of the adjacent bearing rod is the spacing of the grid. Product Spacing (e.g. 19-W-4) refers to the industry specification for Bar Grating products. For example, the first number refers to the bearing bar spacing measured on center (19 = 19/16″ or 1-3/16″), the letter refers to the construction type (W = welded), and the last number references the cross bar spacing measured on center (4 = 4″).

3. Primary Material / Product Finish: Carbon steel products are available in hot-dipped galvanized, black powder-coated, or gray powder-coated finishes.

4. Bearing Bar Size & Shape: Besides, choose the bearing bar height and thickness (e.g. 1-1/4″ Height x 3/16″ Thick) and the shape (Rectangular Bar, I-Bar, or T-Bar).

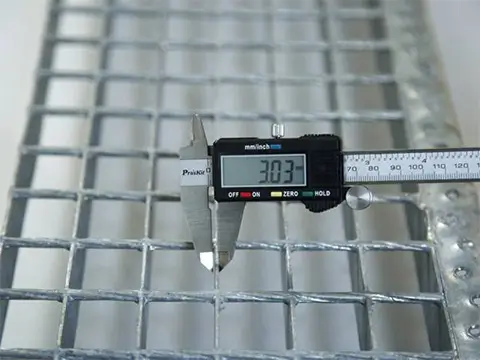

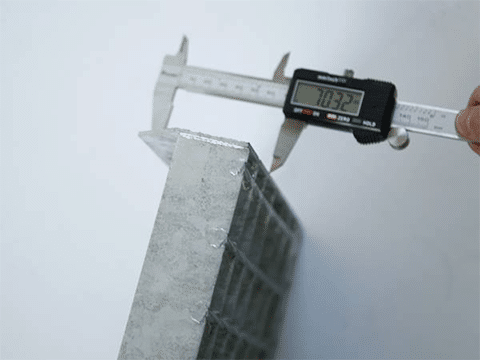

Thickness test of galvanised steel walkway

Thickness test of galvanized steel bar grating

5. Product Surface: Determine if your application requires a smooth, serrated, or grooved product surface.

6. Span: Choose the direction the bearing bars need to run to support the application load. Bearing bar direction is often referred to as span. Clear Span refers to the distance between Bar Grating supports. Bearing bar direction is an important installation consideration.

7. Product Size, Form, & Quantity: Identify the number of panels (width and length) and/or sizes (cut-to-size pieces, areas, stair treads) and cut types (random, uniform, equal stub).

8. Accessories: Determine if Bar Grating Accessories like Clips or Fasteners/Hardware, Carrier Plates, etc. are needed for your project or application.

9. Construction Type: Choose from Standard-Duty Welded, Heavy-Duty Welded, Swage-Locked, Press-Locked, or Clinched construction types.

Steel Grating Saluran

galvanised grating

Galvanized Steel Grating Manufacturer – Wanzhi Steel

Grating is a strong, high-performance, low-maintenance, and non-slip product that can withstand the load of pedestrians or vehicles. Common material types include aluminum, carbon steel, powder-coated carbon steel, galvanized steel, and stainless steel. Wanzhi Steel has established a multilingual team and a dedicated quality inspection department as a high-quality supplier in China. For export galvanized steel grating, we accept customization of size and specifications to meet your requirements.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei Province, China. For 14 years, we have been specializing in the production of stainless steel grating, Steel Grating Plate, aluminum bar, Diamond Mesh Lath, aluminum expanded metal, Expanded Metal Grating, grating platform, serrated steel grating, sidewalk grating, and grating floor with a monthly output of 1800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message