Galvanised Welded Mesh Panel

Material: Q195/Q235 Low-carbon steel wire, galvanized steel wire

Wire Diameter: 1.6-8 mm

Delivery time: 8-18 days

Transportation: By land, by sea

Galvanised Welded Mesh Panel

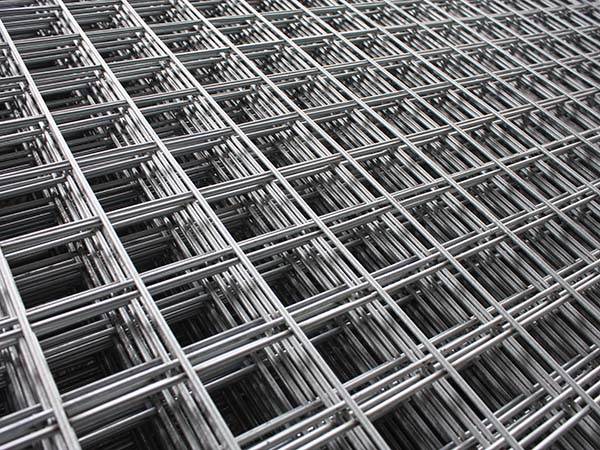

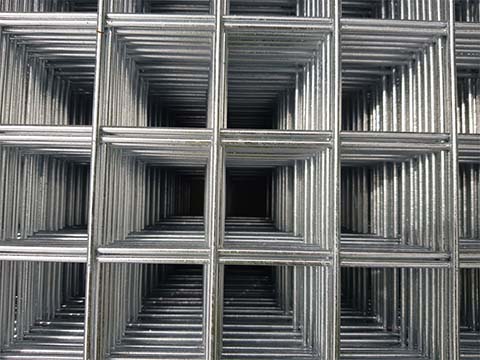

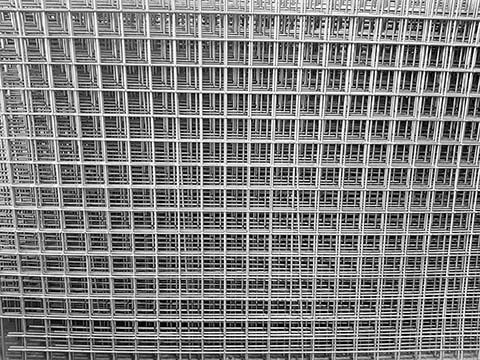

Galvanised welded mesh panel is made by welding thick steel wires to form a rectangular or square mesh hole. The galvanised finish offers excellent corrosion resistance and silver coloured appearance. Due to its great durability, rigidity, and strength, it is suitable for a range of applications, such as Galvanised Garden Wire Mesh, animal cages, pond covers, construction uses, etc. At Wanzhi Steel, we stock a large range of wire mesh products available in both light and heavy gauge, apertures, and mesh sizes. Feel free to ask for an online Quote!

Galvanized Welded Panel

GI Weld Mesh

Specifications

| Item | Galvanised welded mesh panel |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Technique | Welding |

| Opening Shape | Square, rectangular |

| Surface treatment | Hot-dipped galvanized or Electro-galvanized |

| Opening Size | 1/2”-6” (13 mm-150 mm), such as 25*25, 25*50, 50*50, 75*25 |

| Width | Customizable |

| Length | Customizable |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Features

- Strong corrosion resistance: The dense zinc layer formed by galvanizing on its surface can isolate air, moisture, and chemicals, and its service life is 3-5 times longer than that of ordinary wire mesh, especially in humid environments.

- Stable structure: The low-carbon steel wire or stainless steel wire is cross-welded by automated welding equipment, the welds are firm, the mesh is flat, and even if it is partially cut or damaged, it will not cause the whole to loosen, and it has excellent impact resistance.

Galvanized stainless steel welded mesh

galfan coated welded wire mesh

- High strength and light weight: Strictly select high-strength low-carbon steel wire, which has both light weight and high load-bearing capacity, is easy to transport, install, and secondary processing, and reduces the load on the supporting structure.

- Various surface treatments: Hot-dip galvanizing or electro-galvanizing can be used. The former has a zinc layer thickness of 60-100μm and has the best anti-corrosion performance; the latter has a zinc layer of 5-15μm and has a lower cost.

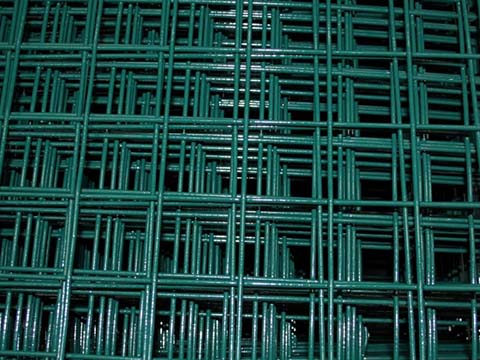

- Color selection: After spraying or coating with PVC coating, it can achieve appearances such as green, gray, black, brown, etc., which enhances the aesthetics and further extends the service life.

- Customizable: The mesh size covers 12.7mm-152.4mm (1/2 inch-6 inches), the panel size can reach 2m×4m, and special specifications can be customized.

- Outstanding economic efficiency: The galvanized welded mesh has a low installation cost, simple maintenance, and a lower comprehensive cost for long-term use.

Galvanised Welded Mesh Panel Case

98 tons of GI welded mesh shipped to Turkmenistan

98 tons of galvanized welded mesh shipped to Turkmenistan

Uses

- Protective isolation: make fences, walls, temporary baffles to protect safety or divide areas (such as construction sites, factories, and residences).

- Agricultural breeding: build poultry and livestock cages and orchard fences to prevent animals from escaping or destroying crops.

- Building reinforcement: use as steel mesh to enhance the strength of concrete structures (such as floor slabs and pavements).

- Industrial application: make shelf layers, equipment protection nets, and mine safety nets to improve space utilization and safety.

- Transportation and municipal administration: make road sound insulation screens, drainage grilles, and bridge protection nets to reduce noise or prevent blockage.

- Decorative landscape: build garden fences, balcony guardrails, or combine plants to create green landscapes.

Wire Mesh Fence

Animal Cage

White 3D Panel Fence

What Is Galvanised Welded Mesh Panel?

Galvanized welded mesh panel is a kind of welded mesh. As the name implies, it is manufactured by welding steel wires into rectangular or square structure. Compared to wire mesh roll (using wire diameters of 0.6 mm to 2.00 mm), panels use thicker wires. According to the making method, there are different kinds of panels to choose from.

- Hot-dipped galvanized before welding (GBW) mesh panel.

- Hot-dipped galvanized after welding (GAW) mesh panel.

- Electro-galvanized before welding (GBW) mesh panel.

- Electro-galvanized after welding (GAW) mesh panel.

GBW Wire Mesh

GAW Wire Mesh

GBW and GAW panel

- GBW mesh panel actually uses galvanized wires as raw materials. After welding, the zinc coating of the joints will be burned away, which will lose the galvanizing protection against rust and corrosion.

- GAW meshes use low carbon steel wires as raw materials. Then the whole mesh panel will be fully galvanized. It will be more durable.

Below are their differences.

| Item | Material | Making Method | Anti-corrosion |

| Hot-dipped galvanized before welding (GBW) mesh panel | Galvanized wire | Galvanized first, then welded into mesh | Great |

| Hot-dipped galvanized after welding (GAW) mesh panel | Low-carbon steel wire | Welded into mesh first, and then hot-dip galvanized | Excellent |

| Electro-galvanized before welding (GBW) mesh panel | Galvanized wire | Galvanized first, then welded into mesh | Good |

| Electro-galvanized after welding (GAW) mesh panel | Low-carbon steel wire | Welded into mesh first, and then electro-galvanized | Great |

GI Weld Mesh Panel

Weld Mesh Panels

Galvanised Welded Mesh Panel Types

1. Hot Dipped Galvanized Welded Mesh Panel

It is galvanized by immersing the wires or mesh panels in a bath of molten zinc at a temperature of around 450 °C. Generally, hot-dip galvanized products have a thicker zinc coating and offer better corrosion resistance.

2. Electro-galvanized Welded Mesh Panel

Electro-galvanizing is also known as cold galvanizing. The zinc coating is applied by electroplating, running a current of electricity through zinc solution with a zinc anode and steel conductor. Compared to hot-dip galvanized mesh, electro-galvanized one has a thinner zinc coating (less than 30 g/m2). But it has a smoother surface and also, it will be much cheaper.

3. PVC-coated Welded Mesh Panel

At Wanzhi Steel, we also have galvanised welded wire mesh sheets with a plastic coating. The PVC coating makes it more corrosion and weather-resistant. Also, PVC wire mesh offers more color options. The most popular colors are green, black, white, etc.

Hot-dip Galvanized Welded Mesh Panel

PVC Coated Welded Mesh Panel

Galvanised Welded Wire Panel VS Welded Reinforcement Mesh Panel

The differences between common galvanized mesh panels and reinforced welded mesh are obvious.

1. Different Wire Diameters

Generally, the common wire mesh uses thinner wire, while the welded reinforcement concrete mesh uses thicker wires or rebar.

2. Different Materials

The material is the essential difference between them. Galvanized welded wire mesh uses low-carbon iron wire or galvanized wire as the base material, which is welded by automated equipment. Concrete welded wire mesh uses steel bars as the base material, with relatively thick wire diameter and heavy weight.

3. Different Applications

The welded reinforcement mesh is mainly used in construction works like bridges, buildings, highways, tunnels, and so on. The common welded mesh panel has a wider range of applications. It is ideal for garden fencing, floor heating mesh, animal enclosures, tree guards, security panels, climbing plant support, etc.

Galvanized Welded Mesh

Welded Reinforcement Mesh

So how to choose a suitable wire mesh? The first thing is to depend on the use purpose. Here is an example: for a small bird aviary, we would recommend wire mesh with smaller gaps. For example, the 13*13 wire mesh will be the most appropriate.

Wanzhi Steel Quality Inspection

Tensile strength test

40 60 90 Salt Spray Tester

Wire Diameter Measurement

Tips on Transporting Galvanised Wire Panels

When transporting your GI welded mesh panels, there are a few things that you have to pay attention to:

1. Place a layer of protective pad under the mesh panels in order to avoid damage during transportation.

2. Do not place sharp objects with them. Otherwise, the zinc layer on the surface may be scratched, and which may cause rust.

3. Put GI welded mesh panels in a straight and reverse way, and tie them closely with ropes to make sure it is safe during transportation.

4. Use waterproof covers rather than putting them in the open air. It will protect the mesh panels from humid conditions.

At Wanzhi Steel, our products are often packaged with waterproof kraft paper inside and then plastic films outside, and then be fixed with pallets.

Welded Mesh Package

Standard Packaging

Welded mesh panel Manufacturer -Wanzhi Steel

Galvanised welded panel is durable and long-lasting to use, also, its silver-coloured appearance means it can be used directly. Wanzhi Steel specializes in the production and supply of galvanized welded mesh in various sizes. With different substrate options and customized services, we provide fast delivery.

For more information, welcome to Contact Us online!

or send email to info03@wanzhisteel.com.

Wanzhi Steel is an ISO: 9001 certified factory located in Hebei, China, with an annual output of 20,000 tons. We specialize in the production of Gi expanded metal lath, Diamond Mesh Lath, Welded Wire Fabric, Wire Mesh For Concrete Slab, and Galvanised Steel Mesh Panels for 14 years, we have exported to more than 120 countries with our high-quality products and good after-sales service.

Leave Us A Message