Copper Clad Steel Wire

Material: Copper Clad Steel

Thickness: 0.08 mm – 4.0 mm

Delivery Time: 15-21 days

Transportation: By sea, by land

Copper Clad Steel Wire

Copper-clad steel wire is a bimetallic composite material consisting of a high-strength steel core covered with copper via electroplating or hot-pressing. It combines the mechanical strength of steel with the conductivity and corrosion resistance of copper, offering a high cost-effective solution. It is primarily used in high-frequency signal transmission (such as coaxial cables and telephone lines), power grounding grids, overhead conductors, and specialized applications requiring high-strength conductors. Wanzhi Steel is a manufacturer and supplier of copper-clad steel wire, offering a wide range of diameters and packaging options. If you are interested, please contact us for more details.

CCS WireT-CCS Wire for USBcoaxial Cable

High Conductivity Copper Clad Steel CCS Wire

Specification

| Item | Copper clad steel wire(CCS Wire) |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Conductor Type | Solid |

| Customized support | OEM, ODM |

| Conductivity | 14-40% |

| Elongation | 8-20%, 1-20% |

| Copper content | 3-35% |

| State | Soft/Hard |

| Color | Copper |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Product Overview

Copper-clad steel conductors are used as flexible connectors for power transmission and distribution equipment (such as transformers and electric furnaces), electronic equipment, and thyristors. They are also used as grounding wires in underground power lines. They can also be manufactured according to customer drawings and specifications.

Copper-clad Steel Grounding Round Wire

Closer view of the CCS wire

Six Core Features

1. Strong and Tough Combination, Excellent Mechanical Properties

The steel core provides extremely high tensile strength and creep resistance, far exceeding that of pure copper wire. It is durable and can withstand mechanical stress in harsh environments.

2. Highly Cost-Effective, Cost-Effective

While maintaining key performance, the unit cost is significantly lower than that of pure copper, significantly reducing raw material costs and embodying a perfect balance between performance and cost.

3. Conductive and Corrosion-Resistant, Balanced Performance

The outer copper layer ensures excellent electrical conductivity and superior atmospheric corrosion resistance. While its conductivity is lower than that of pure copper, it is sufficient to meet the needs of a wide range of applications.

4. High-Frequency Compatibility, Efficient Transmission

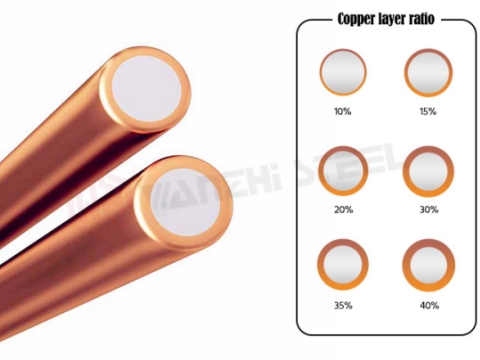

Copper layer thickness cross-section

Utilizing the “skin effect,” when transmitting high-frequency signals (such as radio frequency), current flows only in the outer copper layer, resulting in performance comparable to pure copper wire.

5. Easy Processing, Reliable Connections

It has good ductility, making it easy to bend, braid, and process. The surface copper layer enables reliable soldering using conventional processes.

6. Lightweight and Thermally Stable

It is lighter than pure copper, yet stronger and more thermally stable than copper-clad aluminum wire, with a lower coefficient of thermal expansion.

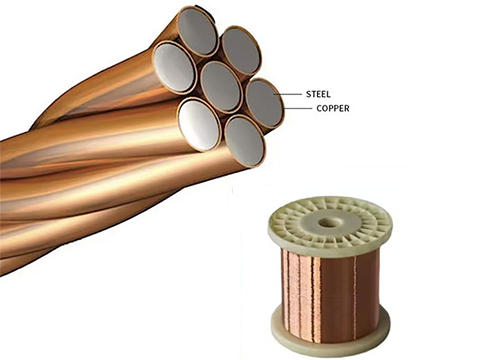

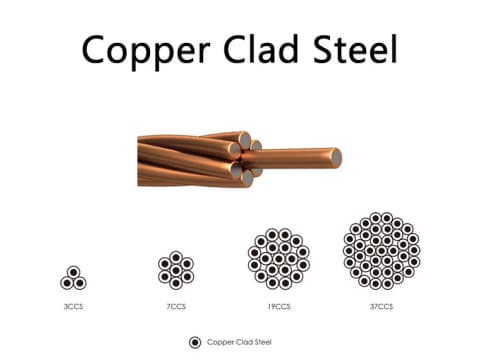

Copper clad steel wire structure

Copper Clad Steel Cable Rope Strand Structure

ASTM Standard Copper and Copper Alloy Grades

Pure or Low-Alloy Copper – High Conductivity

- C11000: Oxygen-free copper is the most commonly used and is the preferred choice for high conductivity requirements.

- C10100 – C15760: A range of high-conductivity pure and low-alloy copper designations.

Brass – Excellent mechanical properties and machinability

- C27000: 65/35 brass, 65% copper, 35% zinc. Offers good strength and ductility.

- C27400: 63/37 brass, 63% copper, 37% zinc. Very common, with excellent cold working properties.

- C28000: 60/40 brass or Muntz brass, 60% copper, 40% zinc. Offers higher strength and is often used in heat exchange and corrosion-resistant components.

Special Copper Alloys

- C44300, C44400, C44500: Admiralty brass/arsenic brass, with small additions of tin, arsenic, or antimony, offers excellent resistance to seawater corrosion and dezincification.

- C60800: Aluminum bronze, primarily aluminum, offers exceptional strength, wear resistance, and excellent corrosion resistance. It has relatively low electrical conductivity but excellent mechanical properties.

copper coated steel wire

C27000/27400/28000/33000/33200/37000 CCS Wire

Main Application Areas of CCS Wire

Communications

Used in the inner conductor and shielding braid of coaxial cables, ensuring low-attenuation transmission of high-frequency signals and effectively suppressing electromagnetic interference. It is a key foundational material for 5G base stations, cable television, and radio frequency communication networks.

Power Systems

Widely used in overhead ground wires, jumpers, and binding wires for transmission lines, substation grounding devices, and lightning protection systems, as local loop (last mile) customer drop wires.

Transportation

Used in electrified railway catenary systems and critical automotive wiring harnesses. Suitable for vibration-resistant areas such as battery harnesses and door control cables.

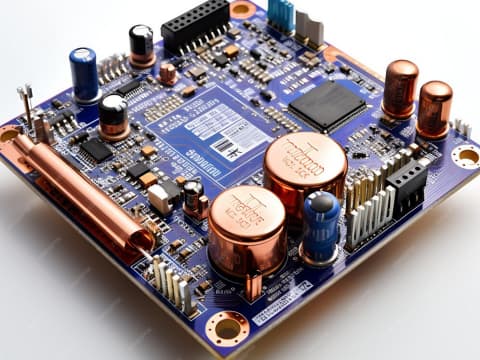

Electronic Manufacturing

Used in electronic component pins, electromagnetic coils, and shielding components. Widely used in products such as motors, transformers, heating elements, and spring contacts.

Building Lightning Protection

Used in the manufacture of ground rods and lightning protection down conductors, leveraging the corrosion resistance of the copper layer to achieve long-term, reliable lightning protection. Suitable for grounding systems in various buildings and communication base stations.

RF communication network wires

integrated circuit solder joints

Grounding wire

Recommended areas for different coating materials

- C10100-C15760: Standard power and communication cables for applications requiring high conductivity.

- C27000: General-purpose applications requiring good mechanical strength and a certain degree of conductivity.

- C27400: Components requiring complex processing and forming (such as specialized terminals).

- C28000: Applications requiring high mechanical stress and wear resistance.

- C44300-C44500: Grounding and cables for harsh corrosive environments such as ships, offshore wind power plants, and coastal areas.

- C60800: Special connectors for heavy equipment, mining sites, and applications requiring high strength and wear resistance.

Physical Properties

| CCS Wire | |||||

| Technical Characteristics | Conductivity(min at 20℃) | ||||

| 15% | 18% | 21% | 30% | ||

| Size range | 0.12mm-8.00mm | ||||

| Resistance (max at 20℃) |

0.116Ω.mm/m | 0.0969Ω.mm/m | 0.083Ω.mm/m | 0.058Ω.mm/m | |

| Density | 7.88g/cm³ | 7.90g/cm³ | 7.95g/cm³ | 8.10g/cm³ | |

| Elongation | H | 1%-3% | |||

| A | 8%-25% | ||||

| Tensile strength | H | 430Mpa-1800Mpa | |||

| A | 320Mpa-560Mpa

320Wpa-560Mpa 320Mpa-560Mpa 320Mpa-560Mpa |

||||

Copper Clad Steel Cable CCS Wire

Copper Clad Aluminum Cable CCA Wire

Process Characteristics

Copper-clad steel conductors are coated with copper on a steel coil using a cladding or electroplating process, forming atomic bonds between the two metals, which allows them to be processed as a single metal. During the drawing, annealing, and stretching processes, the ratio of copper to steel changes with diameter, but the copper content remains constant.

Due to the “accelerated skin effect” of high-frequency signals, copper-clad aluminum wire and copper-clad steel wire have the same conductivity as pure copper wire at high-frequency signal transmission (above 5 MHz).

Product Parameters(CCS wire)

| Diameter (mm) | Conductivity(%) | Elongation(%) | Copper content(%) | State | Packing plate |

| 0.08 | 14-40 | 8-20 | 3-35 | Soft | 100P/200P |

| 0.09 | 14-40 | 8-20 | 3-35 | Soft | 100P/200P |

| 0.1 | 14-40 | 8-20 | 3-35 | Soft | 100P/200P/185P |

| 0.12 | 14-40 | 8-20 | 3-35 | Soft | 100P/200P/185P |

| 0.15 | 14-40 | 8-20 | 3-35 | Soft | 100P/200P/185P |

| 0.2 | 14-40 | 8-20 | 3-35 | Soft | 200P/185P/250P |

| 0.25 | 14-40 | 8-20 | 3-35 | Soft | 185P/250P/350P/400P |

| 0.3 | 14-40 | 1-20 | 3-35 | Soft/Hard | 185P/250P/350P/400P |

| 0.32 | 14-40 | 1-20 | 3-35 | Soft/Hard | 185P/250P/350P/400P |

| 0.4 | 14-40 | 1-20 | 3-35 | Soft/Hard | 250P/350P/400P |

| 0.5 | 14-40 | 1-20 | 3-35 | Soft/Hard | 250P/350P/400P |

| 0.6 | 14-40 | 1-20 | 3-35 | Soft/Hard | 350P/400P/500P |

| 0.643 | 14-40 | 1-20 | 3-35 | Soft/Hard | 400P/500P |

| 0.813 | 14-40 | 1-20 | 3-35 | Soft/Hard | 400P/500P/630P |

| 1.024 | 14-40 | 1-20 | 3-35 | Soft/Hard | 400P/500P/630P |

| 2 | 14-40 | 1-20 | 3-35 | Soft/Hard | 500P/630P |

| 4 | 14-40 | 1-20 | 3-35 | Soft/Hard | 500P/630P |

| Other models Can Contact Us To Customize | |||||

Product Packaging

Wooden reel packaging

0.25/0.50/0.60mm for Electronic Cables

Ccs Wire 30% 40% Conductivity

Copper-Clad Steel Wire Manufacturer- Wanzhi Steel

Wanzhi Steel relies on advanced production technology, fully automatic large-scale production lines, and strict quality control systems to provide customers with high-performance and highly consistent copper-clad steel wire products.

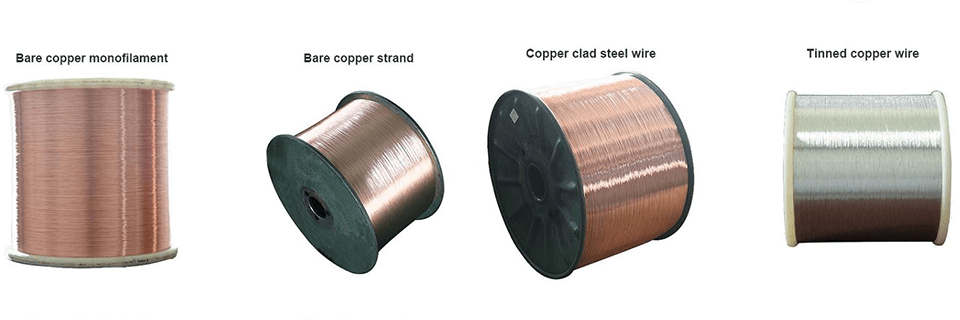

Copper wire and copper-clad products

Why Choose Us?

- Advanced Production Technology: Utilizing electroplating and cold-drawing techniques, we ensure a metallurgical bond between the copper layer and the steel core, guaranteeing excellent conductivity and bond strength.

- Large-Scale Production Capacity: Our fully automated production line boasts an annual production capacity of 400,000 tons, ensuring a stable supply and the ability to deliver large orders.

- Strict Quality Control: Our products comply with international standards such as ASTM, ROHS, and REACH, and are equipped with online testing equipment for 100% quality control of dimensions and performance.

- Customized Solutions: We can customize specifications, copper layer ratios, and surface treatments to meet customer needs, providing personalized product services.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001 certified steel factory, located in Hebei Province, China, specializing in the production of Galvanized wire, Annealed wire, Stainless steel wire, Galfan wire, Aluminum wire, Low carbon wire, with a monthly output of 1,800 tons. With high-quality products and good services, the products have been exported to more than 120 countries around the world.

Leave Us A Message