Chain link fencing has become one of the most common choices for residential, commercial, and industrial applications due to its economic practicality, durability, and relatively simple installation. If you are considering installing this type of fencing, you will likely have many questions about cost, spacing, materials, and more. This guide will answer them one by one.

Plastic coated black chain link grid

Chain Link Top Railing

Popular colors of chainlink mesh

Why is Chainlink fencing a good investment?

Because of its high cost-effectiveness and long-term returns, metal chain link fencing is not only cheaper than wooden or vinyl fencing, but it also won’t rot, crack, or attract insects, thus requiring almost no maintenance. It can provide a lifespan of up to decades. “One-time installation, long-term benefits,” making it a valuable investment that preserves and increases its value.

How much does chain link fence cost?

The answer varies depending on a number of factors, including fence size, material specifications, and labor costs. A professional chain link fence installation project is typically priced per foot. In the United States, the average price for materials and installation is between $15 and $30 per linear foot. Let’s broaden our perspective and look at the market situation in different regions. For example, how much is chain link fence in Kenya? Prices will vary due to differences in local materials, labor, and transportation costs, and it is also a popular choice in Kenya.

Different chain link fences

You might wonder, “What is a chain link fence made of?” Chain link fence mesh rolls are made of woven steel wire. So, what is the gauge of a chain link fence? Its specifications include wire diameter, aperture, height, roll length, and material.

Wire gauge

Gauge refers to the thickness of the steel wire; the smaller the number, the thicker the wire and the stronger the fence.

11-1/2 gauge is commonly used for residential fences, while 9 gauge or thicker gauges are recommended for commercial or industrial areas requiring higher security.

Vinyl coated GI chain link structure

304 SS chain link mesh production

1.5 Inch galvanized chain link mesh

Classified by material

(1) Vinyl /PVC-coated chain link fence: A layer of colored plastic (PVC) is wrapped around galvanized steel wire, providing better corrosion protection and aesthetics. Available in various colors, such as green and black.

(2) Galvanized chain link fence: The most economical option, the steel wire is galvanized for rust prevention. This is the most common type in the wholesale chain link fence market.

(3) Stainless chain link fence: Stainless steel chain link mesh is mainly used in harsh environments or in medical and chemical fields. Due to its higher price, galvanized diamond mesh is recommended for ordinary environments.

Where to buy and how to install chain link fence?

Once you’ve determined the specifications and budget, the next question is, where to buy chain link fence? You can purchase it from large home improvement markets or professional fence material suppliers. For large projects or contractors, finding a wholesale chain link fence supplier is key to cost control.

For DIY enthusiasts, understanding the installation process is essential. This includes how to properly set up the fence posts, and the most crucial step—how to put the chain link fence together and tighten it.

Rhomboid chain ring structure

Installation Process Overview

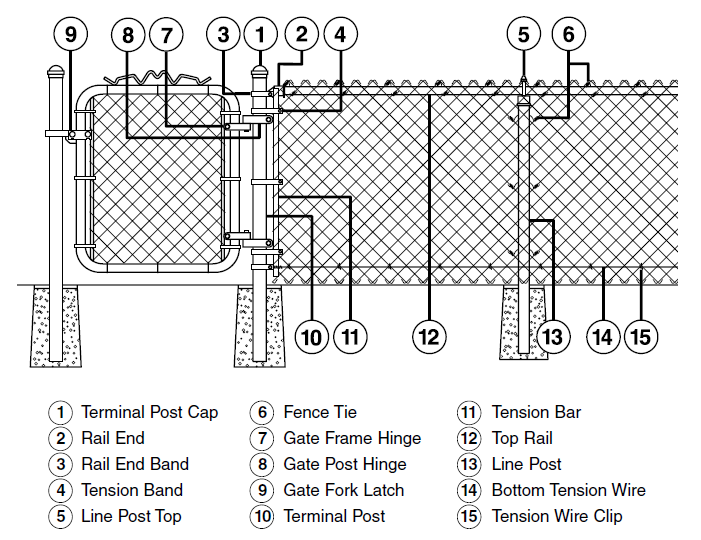

(1) Planning and Setting Up Fence Posts: Determine the spacing of the chain link fence posts (typically 10 feet) according to the standards discussed above and install them securely.

(2) Unrolling the Mesh: How long is a roll of chain link fence? Standard rolls are typically 50 feet or 100 feet long. You will need to cut it to the appropriate length for the actual distance.

(3) Assembling and Tensioning: Use a tension bar to thread the mesh through one end, pull the mesh taut with a tensioning tool, and then secure it to the end posts and wire posts. This process requires some chain link fence stretching skills.

(4) Securing: Use clips to secure the mesh to all the intermediate posts.

Proper stretching is key to a neat and professional-looking fence.

Installation diagram 1

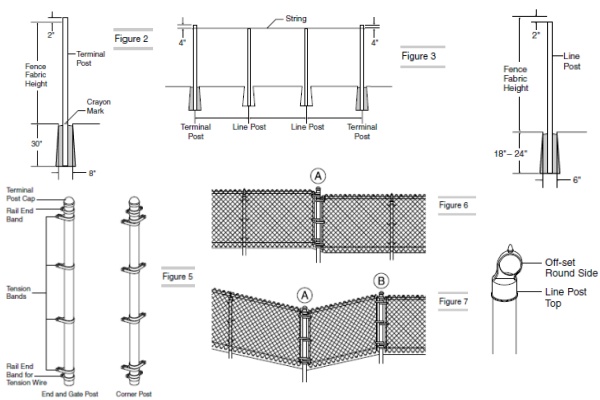

Installation diagram 2

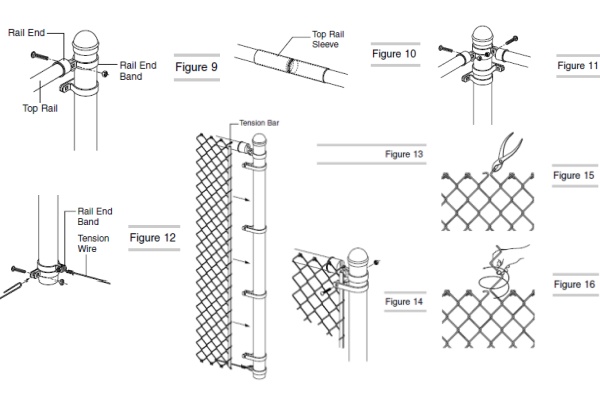

Installation diagram 3

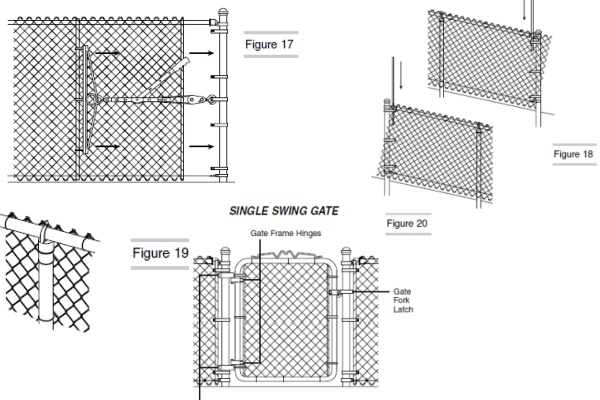

How far apart chain link fence posts?

This depends on the fence height. First, let’s understand “pole posts” and “center posts.”

* Pole Posts (or Corner Posts): These are the posts that bear the main tensile force and are usually placed at corners, ends, or on either side of gates. Their spacing is not fixed, but they must be secure.

* Center Posts: Their function is to support the mesh and prevent it from sagging excessively.

Typically, the standard spacing for chain link fence posts is one post every 10 feet (approximately 3 meters). For taller fences (e.g., over 6 feet), it is recommended to reduce the spacing to 8 feet (approximately 2.4 meters) for better support.

How to repair chain link fence?

Repairing metal chain link fences is quite simple. For small tears or holes, you don’t need to replace the entire mesh. You can use an extra wire, such as the binding wire from the chain link fence, to weave the damaged sides together, like sewing a garment. For severely bent fence posts, it may be necessary to reinforce the base with concrete or replace them.

black chain link fence post

gi cyclone mesh production

Chain Link Single gate

Summary

Planning a successful chain link fence project requires consideration of multiple aspects. From assessing its investment value and cost (whether by foot or understanding market prices in places like Kenya and the Philippines), to choosing different types and specifications of chain link fences, and even the spacing of the fence posts, all are crucial. Understanding what chain link fences are made of will also help you determine their suitability for your application.

During the implementation phase, you’ll need to decide where to purchase materials, consider wholesale options, and plan how to install them, whether to hire someone or learn how to assemble the fence yourself, how to stretch it, and how to repair it later. This guide covers the core issues throughout the entire lifecycle, from decision-making and procurement to installation and maintenance, aiming to provide you with comprehensive knowledge to help you make the right decisions.

82 tons of galvanized chain link fence to Libya

Green and Black PVC coated chainlink mesh to Iran

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized welded wire mesh, crimped wire mesh, Galvanized Square Mesh, diamond mesh for chainlink fence, Galvanized Garden Wire Mesh for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message