Aluminum Wire Rod

Rod Diameter: 2 mm – 16 mm

Tensile Strength: 1860MPa

Transportation: By sea, by land

Aluminum Wire Rod

Aluminum wire rod is a round cross-section wire made of aluminum as raw material, often supplied in the form of coils. It possesses excellent properties, including thermal conductivity, corrosion resistance, and light weight. According to the composition, it can be divided into two categories: pure aluminum wire rod and aluminum alloy wire rod. Wanzhi Steel is a high-quality aluminum wire rod manufacturer in China. We have aluminum wire rods of different series and diameters in stock. If you are interested, welcome to contact us for details.

7075 aluminum round bar

A2017 4032 1100 B211 Aluminum Rod Bar

1050 1060 1100 Grade High Purity Alu Rod

Aluminum Wire Rod Specification

| Item | Aluminium rods |

| Place of Origin | Hebei, China |

| Delivery Time | 10-18 days |

| Standard | ASTM, EN, JIS, DIN, GB |

| Grade | 1000,3000,5000,6000,7000 Series |

| Surface Treatment | Oxidized/Black Painting |

| Al (Min) | 99.7% |

| Ultimate Strength (≥ MPa) | 150-400MPa |

| Elongation (≥ %) | 5%-25% |

| Processing Service | Bending, Punching, Cutting, Weaving |

| Surface Finish | Brushed, polished, mill finish, powder coated, sandblast |

| Temper | O, F, T3, T5, T6, T651, T6510, etc |

| Price Term | Ex-work, FOB, CIF, CFR, etc |

| Payment Methods | TT 30% prepaid |

| Packing | Standard Sea-worthy Packaging |

| Sample | Free available |

| MOQ |

5 Tons

|

aluminum wire rod

8mm aluminum rod

10 ga Zinc Aluminum Alloy Wire

Commonly used aluminum series

- 1050: Excellent conductivity, good ductility, strong corrosion resistance, good weldability, can be anodized, and has the lowest strength.

- 1060: The most commonly used grade of pure aluminum, slightly higher purity than 1060, better conductivity, excellent corrosion resistance, excellent formability and surface treatment, and low cost.

- 1070: The highest purity, excellent corrosion resistance, and best conductivity, but the lowest strength and soft hardness.

- 1100: Contains a small amount of Cu, slightly higher strength than 1060, slightly worse corrosion resistance, but good formability and weldability.

- 3003: The most commonly used 3 series alloy, with a strength about 20% higher than pure aluminum, good formability and corrosion resistance, can be welded, and cannot be heat-treated and strengthened.

- 5052: Medium-high strength, outstanding corrosion resistance (especially salt spray corrosion resistance), excellent formability, can be anodized, and significant work hardening.

- 5083: High-strength alloy, good fatigue resistance, extremely resistant to marine environment, excellent weldability.

- 6061: Excellent overall performance, medium strength, heat treatment can improve strength, good corrosion resistance, easy anodizing.

- 6063: Low strength, high plasticity. The strength is slightly lower than 6061, but the formability is better, and the surface anodizing effect is excellent (surface beauty).

7075 6061 6063 T5 Aluminum Alloy Rod

Aluminum Wire Rod Supplier

Aluminum wire rod performance characteristics

1. Excellent conductivity

Aluminum rods have excellent conductivity and are suitable for the manufacture of electrical equipment such as wires and cables.

2. Good corrosion resistance

Aluminum stick rods can form a dense aluminum oxide film in the air, which has good corrosion resistance.

3. Lightweight and high strength

Aluminum wire rods have a low density but high strength, which is suitable for occasions where weight reduction is required.

4. Easy to process

Aluminum wire rods have good plasticity and ductility and are easy to process by rolling, drawing, etc.

5. Cost-effectiveness

Compared with other metal materials, its price is relatively low.

6. Good mechanical properties

It has certain strength and toughness and can withstand certain tension and pressure.

1050 Aluminum wire rod

10 swg aluminum-wire-rods

What are aluminum rods used for?

Power and electronics

- Overhead transmission lines: Aluminum stranded wire (AAAC all-aluminum stranded wire, ACSR steel-core aluminum stranded wire) is commonly used in high-voltage transmission lines, thanks to the high conductivity and light weight of aluminum.

- Cable conductor: The core wire used for power cables and control cables, especially suitable for indoor wiring and building cables.

- Electromagnetic wire: After being drawn into fine aluminum wire, it can be made into enameled wire for windings of motors, transformers, and household appliances (air conditioning compressors).

- Batteries and new energy: In the production of lithium batteries, aluminum foil wire can be used as a current collector material or as a connecting wire for battery components.

Communications and networks

- Some communication cables (unshielded twisted pair) use aluminum conductors to reduce costs or to strengthen the shielding layer of signal transmission lines.

Aviation Cable

Lightweight frame fixing

Transmission line post

Construction and decoration

- Rebar substitute or auxiliary material: Aluminum wire can be used to bundle light steel structures, temporary building components or as a light connection material.

- Decorative wire: After anodizing and painting, it is made into aluminum ropes and decorative nets for indoor and outdoor decoration (ceiling, curtain wall decoration), furniture weaving aluminum rattan chairs.

Pipes and heat dissipation

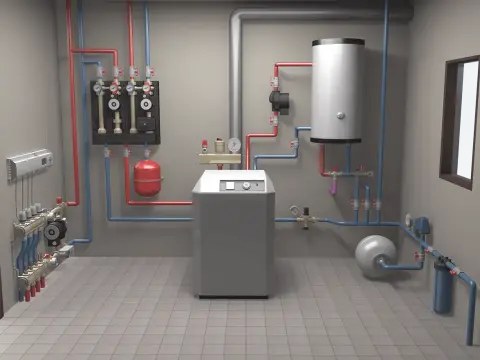

- Aluminum wire can be processed into heat sinks or heat dissipation ribs for the manufacture of building heating systems and electronic equipment radiators.

Packaging and bundling

- Food and medicine: Replace traditional iron wire as aluminum wire soft packaging bundling for food, medicine, and daily necessities.

- Tobacco, textiles, and household use: Used to bundle cigarette paper, cloth rolls, etc. Jewelry making, handicraft weaving, and art.

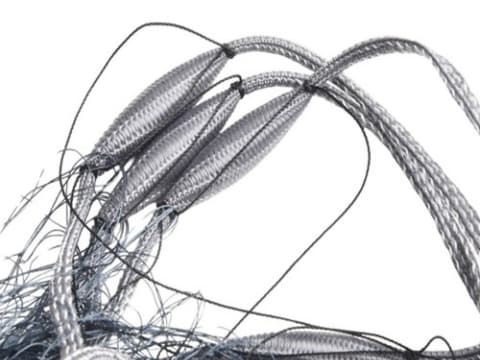

- Agriculture and fisheries: Make reinforcement wires for fishing nets and binding wires for agricultural greenhouses (corrosion-resistant to prevent iron wire from rusting and damaging crops).

Fishing net reinforcement line

Furniture structure display

Highway Cable Fence

- Machinery & Logistics: Used for temporary fixing of parts or wiring harness arrangement; in the logistics industry, used for reinforcement of goods in containers.

Automobiles and transportation

- Automobile wiring harnesses: With the trend of lightweight automobiles, aluminum wires are gradually replacing copper wires for low-voltage wires, reducing the weight and cost of the entire vehicle.

- Transportation facilities: Processed into aluminum steel wire ropes, used for lightweight transformation of highway guardrails and bridge cables, or made into supporting wires for traffic signs.

Aerospace and military industry

- Lightweight components: In the aerospace field, aluminum wire is alloyed to make high-strength wire, which is used for aircraft structural connection, aviation cables, or lightweight design of missile components.

- Military equipment: Used to manufacture lightweight wires for radar antennas, communication equipment, or binding materials for precision instruments.

Precision instrument accessories

Hay baling wire tying

Heating Systems Explained

Aluminum wire rod manufacturing process

The manufacturing process of aluminum wire rods mainly includes raw material preparation, smelting, casting, rolling and drawing, finishing, and inspection.

The rolling and drawing steps are to roll or draw the cast aluminum rod to obtain the required diameter and shape. Rolling is to roll the billet through a rolling mill, while drawing is to stretch the billet through a drawing machine.

Finally, 3/4 of the aluminum rod will be coiled or cut into specified lengths. Coiling ensures easy handling and transportation, especially for large quantities.

Aluminum Wire rods for Sale

5052 Aluminium wire rods in stock

5 8 aluminum rod

Aluminum VS Steel VS Titanium wire rod

Sometimes you may wonder, Are aluminum rods better than steel? In fact, the advantages of aluminum wire are light weight and soft texture, while the advantages of steel wire are high tensile strength, strong mechanical properties, and high hardness.

aluminum brazing rod

close view of aluminum wire rods

The following table summarizes the advantages and disadvantages of aluminum, steel, and titanium wires.

| Material | Pros | Cons |

| Aluminum rod | • Flexibility in construction • Low cost |

Less durable in some cases |

| Steel wire rod | • OEM material | Huge opportunity to improve design |

| Titanium wire rod | • Most durable • Lightweight |

Expensive Short fatigue life |

Aluminium wire rod price

The price of Aluminum wire rods is affected by many factors, including raw material prices, production costs, regional differences, and product quality. However, its price is usually determined by factors such as its purity, diameter, length, and production process. The prices of aluminum wire rods of different specifications will also vary. If you want to know the latest Aluminum wire rod price or price changes, you can contact Wanzhi Steel Online, and we will arrange for an experienced sales manager to give you an accurate quotation.

Package Method

Pallet packaging

aluminum-alloy-wire-rods

5183 4047 Aluminium Wire Rod for Cable

Aluminum rods for sale – Wanzhi Steel

Aluminum wire is a project with a high return on investment. If you are looking for the right material, it is a very suitable choice. Wanzhi Steel also provides a variety of wire diameters to choose from, which will definitely meet your wide range of requirements. You are welcome to send the size or purpose!

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of high-quality Galfan Wire, SS wire, aluminum wire, HDG wire, aluminum wire rods, steel wire rods, Annealed Wire, Oval Wire, and Zinc Aluminum Alloy Wire for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message