What Is High Tensile Wire?

High-strength steel wire is mainly made of carbon steel or alloy steel, also known as high-tension steel wire, which is a steel wire material with excellent tensile strength. The carbon steel wire of this steel wire is 80# steel, and the carbon content is usually between 0.7% and 0.9%. When the carbon content of the steel wire is increased (>0.9%), its effect is the same as cold working and heat treatment, which can improve the strength and hardness of the steel wire. Wanzhi Steel sells different high-tensile wire sizes, which will meet all your requirements. If you are interested in it, please read on or contact us!

High Tensile Wire

High-Quality High Tensile Wire

galvanized mild steel wire low carbon

Features of High Tensile Wire

1. Strong and Durable

It has high strength and good tensile properties. Even under harsh environmental conditions, this wire still performs well. In addition, this wire is very durable and can be used for decades without replacement.

2. Easy to Maintain

Secondly, it has a long service life. Especially when it is surface treated, the corrosion resistance is greatly increased and it can easily last for decades. During this time, it does not require regular maintenance. This also assumes that you will save more effort and time.

3. Cost-effective

Fences made with this steel wire are ideal. This is because of the high strength. It does not require many support posts along the installation, so less material is needed. Therefore, it will cost less to install than other types of fencing.

4. More Secure

Besides, it is much safer for livestock than barbed wire. It can effectively control animals such as cattle, horses, pigs, and sheep without hurting them easily.

hot dipped galvanized wire

Continuous hot dip galvanized wire

9 gauge galvanized wire in stock

Applications of High Tensile Wire

High-tensile wire, with its excellent tensile strength and durability, has a wide range of applications. Its main uses are as follows:

1. Agriculture

It can be used for large-scale farmland fencing to prevent intrusion and wildlife from damaging crops. It can also be used to construct support nets for vine crops (such as grapes and tomatoes) to prevent stems from breaking under the weight of the fruit.

2. Ranching

It is used to contain livestock such as cattle and sheep to prevent them from wandering off or becoming entangled. Its strong weather resistance allows it to survive the open air of pastures for extended periods, reducing the need for frequent fencing replacements.

3. Construction

It is primarily suitable for lifting and hoisting operations (such as lifting rebar and steel structural components). It can also be made into wire mesh and mixed into concrete to improve the crack resistance and load-bearing capacity of walls and floors.

4. Packaging and Other Applications

As baling wire, it is used to compress and bundle bulk materials such as waste paper and metal scrap to ensure they do not fall apart during transportation. It can also be used in forestry to secure tree saplings and in power plant traction systems.

Farm Fence Wire

Its Uses

Vinly coated galvanized iron wire

Is It Easy to Install?

The answer is yes. High tensile wire is easy to install. It has low slack and when installing it, there is no need to pre-stretch the wire, just place it on the post and pull it tight. Because it is much stronger than low carbon steel wire, it can be installed on fewer posts. The high tensile wire will remain tight after installation. It will recover even after a hard impact.

For more about high tension wire, you can refer to – Coated high tensile wire.

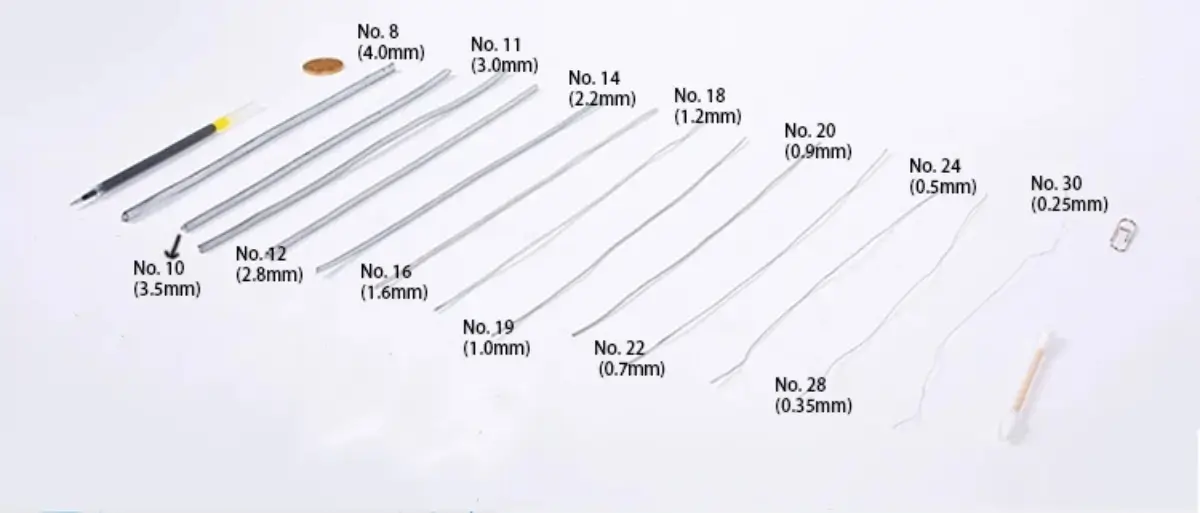

Comparison of different galvanized wire thicknesses

Quality Inspection

1. Appearance Inspection: Check the surface galvanizing layer for uniformity and smoothness, free of defects such as missing plating, peeling, blistering, and black spots. Also, inspect the steel wire for cracks, scratches, and deformation.

2. Dimensional Inspection: Use measuring tools (such as calipers or micrometers) to measure the diameter and length of the steel wire, as well as the coil diameter and flatness of the coiled product.

3. Galvanizing Quality Testing: Test the corrosion resistance of the galvanizing layer through a salt spray test (simulating outdoor conditions, observing whether rust appears over a period of time); or use a cross-hatch test or adhesion test to check the adhesion of the galvanizing layer.

4. Mechanical Property Testing: Test the tensile strength, yield strength, and elongation of the steel wire to verify that it meets the “high-tension” requirements and is resistant to breakage or deformation under stress.

5. Packaging Inspection: Verify that the packaging (such as stretch film or woven bags) is secure and that the labeling (specification, batch, and manufacturer information) is clear and complete.

40 60 90 Salt Spray Tester

Tensile strength test

gi wire wire diameter measurement

Galvanized Steel Wire Gauge Chart

| Wire Gauge Size | SWG (mm) | BWG (mm) | AWG(mm) | Metric (mm) |

| 6 | 4.81 | 5.16 | 4.11 | 5 |

| 7 | 4.47 | 4.57 | 3.67 | 4.5 |

| 8 | 4.06 | 4.19 | 3.26 | 4.00 |

| 9 | 3.66 | 3.76 | 2.91 | – |

| 10 | 3.25 | 3.40 | 2.59 | 3.50 |

| 11 | 2.95 | 3.05 | 2.3 | 3.00 |

| 12 | 2.64 | 2.77 | 2.05 | 2.80 |

| 13 | 2.34 | 2.41 | 1.83 | 2.50 |

| 14 | 2.03 | 2.11 | 1.63 | – |

| 15 | 1.83 | 1.83 | 1.45 | 1.80 |

| 16 | 1.63 | 1.65 | 1.29 | 1.65 |

| 17 | 1.42 | 1.47 | 1.15 | 1.40 |

| 18 | 1.22 | 1.25 | 1.02 | 1.20 |

| 19 | 1.02 | 1.07 | 0.91 | 1.00 |

| 20 | 0.91 | 0.89 | 0.812 | 0.90 |

| 21 | 0.81 | 0.813 | 0.723 | 0.80 |

| 22 | 0.71 | 0.711 | 0.644 | 0.70 |

| 23 | 0.61 | 0.64 | 0.573 | 0558 |

| 24 | 0.559 | 0.56 | 0.511 | – |

| 25 | 0.508 | 0.51 | 0.455 | – |

| 26 | 0.457 | 0.46 | 0.405 | – |

| 27 | 0.417 | 0.41 | 0.361 | – |

Note: The larger the number, the smaller the wire, for example, 12 gauge gi wire is thinner than 9 gauge. In general, lower gauge or thicker wire is best used for stronger projects. At the same time, higher gauge gi wire is suitable for garden and pet fencing.

Packaging and Wanzhi Steel Factory

Galvanized Steel wire production line

Galvanized wire for sale

9 gauge galvanized wire

Where to buy high tensile wire – Wanzhi Steel

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001 certified steel mill located in Hebei Province, China. The company specializes in the production of GI wire, galfan wire, SS steel wire, zinc aluminum alloy wire, annealed wire, low carbon iron wire, binding wire, and baling wire. With 14 years of experience, the monthly output reaches 1,800 tons. With high-quality products and good services, the company’s products have been exported to more than 120 countries around the world.

Leave Us A Message