Stainless Steel Wire Rope

Stainless steel wire rope is made of multiple strands of 304, 316, and other grade SS wires. It is corrosion-resistant, fatigue-resistant, high tensile strength, and wear-resistant. It consists of a rope core, strand core, strand, steel wire, and wire rope. It is used in the fields of petroleum, metallurgy, bridges, etc. Its rope diameter, wire diameter, twisting method, and coil weight can be customized. Wanzhi Steel stocks stainless steel wire ropes of various grades and specifications. If you are interested, please feel free to inquire.

304 stainless steel wire rope

316 stainless steel wire rope

Stainless steel wire rope Specification

| Item | Stainless steel wire rope |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Coil weight | 50-1000KG |

| Color | Custom available |

| Lay | Left-hand regular lay or right-hand regular lay |

| Usage | Cable seal, aircraft cable, etc. |

| Surface treatment | Highly Polished |

| Surface coating | No coating, or PVC PE PP PU, Vinyl optional |

| Tensile strength | 1570MPA, 1670MPA, 1770MPA, 1870MPA, 1960MPA |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | 500m/reel, 1000m/reel, 2000m/reel |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Features

- Corrosion resistance: It can perform well in any environment. Including hot and humid, chemical environments.

- High strength: It can withstand heavy loads and impact loads, with a tensile strength of >515N/mm2

- High-temperature resistance: The heat resistance temperature is 700℃ to 800℃.

- Flexibility: The rope’s inherent characteristics make it very easy to bend and operate, making it suitable for complex installations.

- Abrasion resistance: The smooth surface and multiple strands of iron wire are twisted to extend the service life.

- Aesthetics: The surface is bright, and Wanzhi Steel provides a variety of surface treatments.

- Customizable: Different diameters, structures, and lengths are available, and colors, roll weights, and packaging can also be customized.

Wanzhi Factory- GI SS wire rope in stcock

Stainless Steel Wire Rope Manufacturer

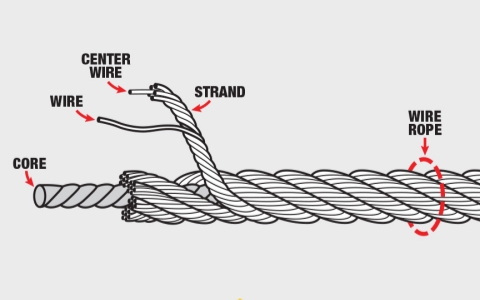

Structural composition

In summary, it is a sophisticated, complex, multi-layered complex consisting of “wire → strand → (+ rope core + lubricant) → rope”.

1. Wire

The most basic unit of a wire rope. Made from stainless steel wire rod through a drawing process, it is a single metal wire of varying diameters.

2. Strand

Composed of multiple steel wires twisted in a specific spiral around a core (the strand). The core can be a single steel wire, a fiber core, or another group of thin steel wires.

3. Core

Located at the very center of the wire rope, it provides support for the entire strand. There are three main types:

Wire rope structure

- Fiber Core (FC): Made of natural or synthetic fibers (such as polypropylene), it makes the rope very flexible but cannot be used in high-temperature environments.

- Independent Wire Rope Core (IWRC): Made of a single, thin steel wire. It can withstand high temperatures and higher compressive loads.

- Wire Strand Core (WSC): Made of a single, independent steel strand, it offers performance and strength intermediate between FC and IWRC.

4. Lubricant

During the twisting process, lubricant penetrates the wires, the strands, and the core. This reduces internal friction and heat buildup, while also preventing corrosion and increasing flexibility.

5. Rope

Multiple strands (usually six) are wrapped around a central core and twisted in the same or opposite direction as the strands, creating a complete wire rope.

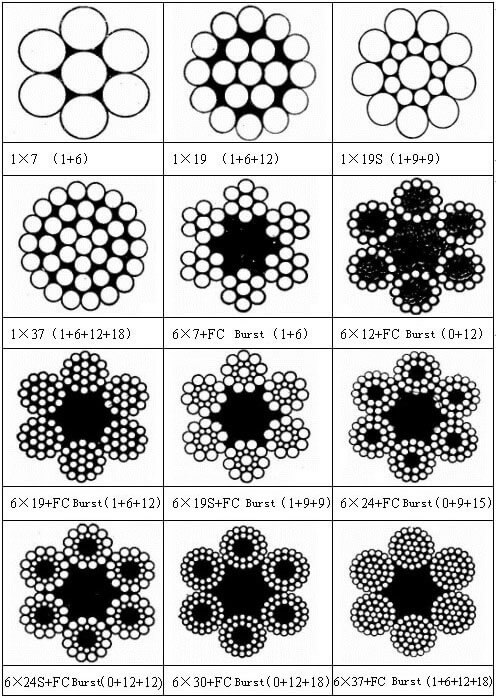

Typical structure & weight formula

- 1×7 structure: 7 strands per strand

- 1×19 structure: 19 strands per strand

- 7×7 structure: 7 strands, 7 strands per strand

- 7×19 structure: 7 strands, 19 strands per strand

- 6×19 structure: 6 strands, 19 strands per strand

- 6×37 structure: 6 strands, 37 strands per strand

- 19×7 structure: 19 strands, 7 strands per strand

Weight calculation formula

Weight = (3.14 × diameter² × 7930kg/m³ × total number of wires in the wire rope) × length / 4

Application

Recommended applications for different diameters

- φ0.5 – φ1.5: Jewelry, model making, surgical wire, internal transmissions for precision instruments, dental equipment.

- φ1.6 – φ3.0: Remote control models, fishing line, brake lines, household tethers, office equipment, small charms.

- φ3.2 – φ6.0: Marine cables, railing cables, stage rigging, mechanical transmissions, pet leashes, furniture applications.

- φ6.5 – φ12.0: Construction safety nets, small lifting equipment, truck winches, dock moorings, mining equipment.

- φ13.0 – φ20.0: Large ship moorings, heavy crane slings, large equipment towing, cableway load-bearing systems, industrial lifting.

Visual comparison of different rope diameters

- φ20.0 and above: Large port lifting equipment, offshore platform moorings, bridge stay cables, and core load-bearing structures for large projects.

Recommended uses for different strand structures

- 1×7: railings, support wires, cable cores

- 1×19: guardrails, cables, mechanical transmission

- 7×7: control cables, light lifting, furniture

- 7×19: stage equipment, elevator cables, ship cables, etc.

- 6×19: heavy lifting, building structures, bridge cables

- 6×37: ship cables, large lifting equipment, mining equipment

- 19×7: precision instruments, aerospace equipment

- Multi-layered structure: deep-sea operations, oil drilling platforms.

Application Areas

- Industrial applications: cranes and elevators, mechanical power transmission, car cockpit lever control. Aircraft control systems.

- Construction: elevated buildings and bridges, stainless steel fences and isolation nets, cable bridge pulling and supporting towers.

- Ship and ocean: ship cables, anchor chains, offshore platform fixing.

- Petrochemical field: oil drilling platforms, chemical equipment hoisting.

- Furniture and decoration: furniture and decoration, stainless steel railing ropes.

- Outdoor: sports facilities, climbing ropes, outdoor cooking utensils hanging systems.

Drilling lifting

Elevator traction pull up

Balcony Fence

Classification of stainless wire rope

- According to the contact state of adjacent layers of steel wire in the strand: point contact, line contact, surface contact stainless wire rope.

- According to the form of the cross section of the strand: round strand, triangular strand, elliptical strand, fan-shaped strand stainless wire rope.

- According to the surface state of the wire rope: smooth stainless steel rope, galvanized (galvanized aluminum alloy) SS steel wire rope, plastic coated stainless steel wire rope.

- According to the structural specifications: single strand, multi-strand such as three-strand, and six-strand stainless steel wire rope.

The significance of single and multi-strand stainless steel rope

We often use A×B to represent the number of strands of wire rope, “A” represents the number of strands, and “B” represents the number of wires.

- Single-strand wire rope: 1×7, 1×19, etc., simple structure, good tensile strength, and wear resistance, but poor softness.

- Multi-strand wire rope: 6×19, 6×37, etc., complex structure, good balance and flexibility.

Stainless steel cable core classification and code

- a Fiber core (natural or synthetic): FC, e.g., FC stainless wire rope.

- b Natural fiber core: NF, e.g. NF stainless steel wire rope.

- c Synthetic fiber core: SF, e.g. SF SS steel wire rope.

Common structures of stainless steel wire rope

- d Metal wire core: IWR (or IWRC), e.g. IWR stainless wire rope.

- e Metal wire strand core: IWS, e.g., IWS stainless steel wire rope.

Cooperation Cases

Morocco 323 tons stainless steel wire rope project

Morocco 323 tons stainless steel wire rope project

What are the coated stainless steel cables?

- Galvanized stainless steel wire rope: suitable for general corrosion, outdoor or humid environment, low cost.

- PVC coating: various colors, easy to distinguish, good wear resistance and corrosion resistance.

- PE coating: good weather resistance and corrosion resistance, more UV resistance than PVC, higher cost.

- Nylon coating: excellent wear resistance, good flexibility, corrosion resistance is not as good as PVC or PE.

- Polyurethane coating: excellent oil resistance, flexibility, fatigue resistance, and higher cost.

- Epoxy coating: extremely strong corrosion resistance, high-temperature resistance, chemical corrosion resistance.

- Teflon coating: low friction, high temperature resistance up to 260°C, excellent chemical corrosion resistance, very high cost.

- Rubber coating: good shock absorption, corrosion resistance, wear resistance, poor high temperature resistance.

PVC coated steel wire rope

Yellow PE Coated 7-19 Steel Wire Rope

Considerations for selecting coated stainless wire rope

1. Use environment: such as humidity, temperature, and chemical corrosion factors.

2. Mechanical properties: such as wear resistance, fatigue resistance, flexibility, etc.

3. Cost: The cost of different coating materials varies greatly.

4. Aesthetic requirements: such as color, surface smoothness, etc.

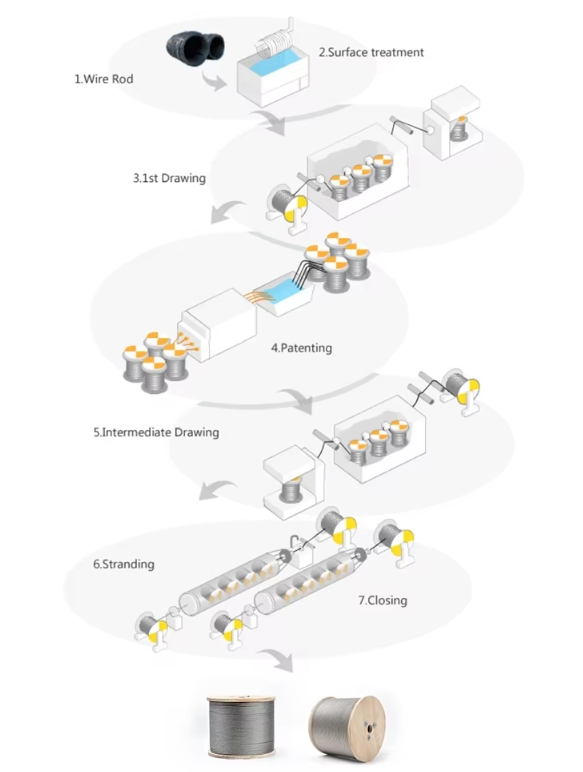

How is stainless steel cable produced?

304 or 316 stainless steel → wire drawing → annealing → single wire twisting / multi-strand twisting → rope closing machine → pre-deformation → annealing → quenching → tempering → polishing → coating (optional) → size inspection → mechanical property inspection → non-destructive inspection → packaging → storage

Wanzhi Steel stainless steel wire rope production line

Wire Rope Manufacturing Process

3 16 steel cable and 304 stainless steel wire rope

316 stainless wire rope is an austenitic stainless wire rope of 18Cr – 12Ni – 2.5Mo, which has better performance than 304 stainless wire rope. Although 304 is also austenitic SS steel, it lacks the Mo element, and its comprehensive performance is slightly lower than 3 16 stainless cable. Except for marine applications, 304 stainless steel cable is sufficient.

Overview of different packaging methods

1. Wooden wheel packaging: large diameter, long length wire rope.

2. Iron wheel packaging: suitable for medium diameter and length.

3. Plastic wheel packaging: small and medium diameter and length.

4. Reel packaging: plastic or paper reel, suitable for small diameter, short length wire rope.

5. Bundling packaging: wrapped with moisture-proof paper or plastic film and directly bundled, suitable for short length and small diameter.

6. Pallet packaging: multiple rolls for batch transportation.

Ss wire rope Manufacture – Wanzhi Steel

Stainless steel wire rope offers excellent corrosion resistance, high strength, and flexibility, making it widely used in construction, marine, and other fields. Its durability and low maintenance make it a promising investment. Selecting a high-quality supplier is crucial. Wanzhi Steel, with its extensive production and export experience, 24-hour response time, and excellent reputation, is a trustworthy and reliable partner.

Stainless Steel Wire Rope Supplier

Reel Packaging

Pallet packaging

Why Choose Us?

- Advanced machinery: Fully automatic CNC stranding machines, rope closing machines, and intelligent heat treatment production lines ensure precise structure, consistent strength, and stable performance.

- Flexible Customization: Supports customization of a variety of materials, structures, and sizes, and quickly responds to special surface treatment and specification requirements.

- Fast and Reliable Delivery: Leveraging scaled production capacity and an efficient supply chain, we maintain ample inventory for standard products, flexible scheduling for custom orders, and on-time delivery.

- Price Competitiveness: Integrating the entire chain from raw material procurement, production, processing, and sales, we optimize cost control and offer highly competitive pricing with outstanding value for money.

- Strict Quality Assurance: Equipped with testing equipment such as spectrometers, tensile testing machines, and salt spray test chambers, we conduct multiple inspections of raw materials, semi-finished products, and finished products.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of SS wire rope mesh, cyclone mesh, perforated stainless steel sheets, Stainless Steel Handrail Cable, and Stainless Steel Cable, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message

- Steel Reinforcement Mesh

- Galvanized Concrete Mesh

- Galvanized expanded metal mesh

- Brick reinforcing mesh

- Stainless Steel Handrail Cable

- Stainless Steel Cable

- Stainless Wire Rope

- Steel Wire Rod

- Steel Strand

- Stainless steel rope net

- 304 stainless steel

- 316L stainless steel

- 430 stainless steel

- Stainless Steel Rope Mesh