Stainless Steel Wire Mesh

Stainless steel wire mesh is a metal mesh made of stainless steel wires that are woven or welded together. It is an extremely versatile wire mesh with high corrosion resistance and stable filtration performance. It can be used for a long time in corrosive environments such as humidity, acid, and alkali without rusting. Wanzhi Steel is a high quality and advanced technology stainless steel wire mesh manufacturer and supplier in China. We stock a large quantity of 304/316/430 grade SS wire mesh, and the size, hole shape can be customized. If you are interested, welcome to contact us for more.

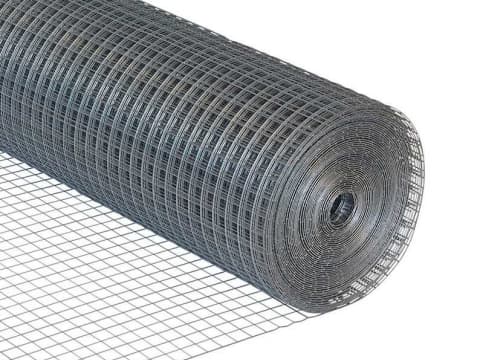

Welded Wire Mesh 304 stainless steel

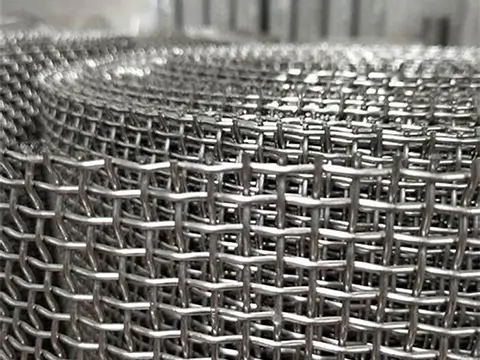

Stainless Stee304 316 Woven Hard Wire Cloth

stainless steel chicken wire mesh net

Stainless steel wire mesh specification

| Item | Stainless steel wire mesh |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Type | Weaving or welding |

| Material | 304/304l/316/316l Stainless steel wire |

| Hole shape | Square, rectangle, hexagon |

| Wire diameter | 0.06mm-0.30mm(8GA-24GA) |

| Length | 5-100m/roll,<12m/piece |

| Height | 0.8-2.0m |

| Mesh hole size | 10×10mm 15×15mm, ,20×20mm,30×30mm,customize |

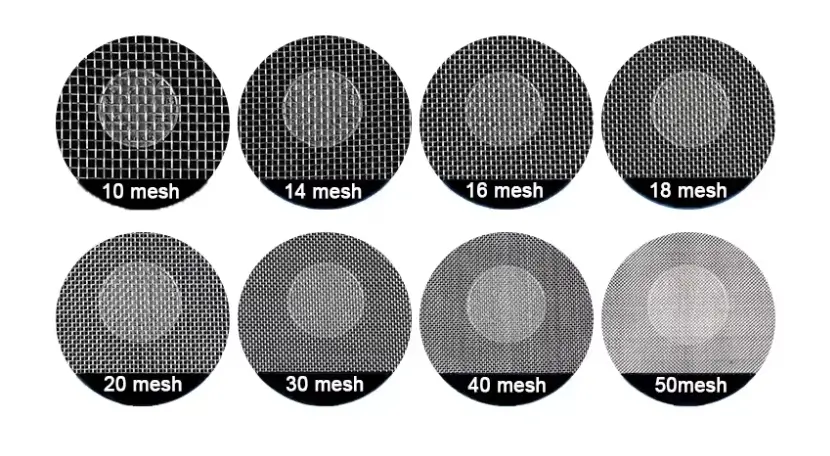

| Mesh count | 1-635 meshes |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Available |

| Price Item | FOB, CIF, EXW, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons |

| Transportation | By sea, by land |

Common grades

Common materials for stainless steel wire mesh include 302, 201, 304, 304L, 316, 316L, 310, 310S, 904, 321, 2205, etc. The characteristics of different materials are as follows:

| Grade | Corrosion resistance | High temperature resistance | Cost | Typical scenarios |

| 304 | Medium (weak corrosion) | ≤800℃ | Medium | Food, water treatment, daily protection |

| 316/316L | Strong (seawater, acid) | ≤650℃ | High | Chemical, marine, medical |

| 310S | Medium (normal temperature) | ≤1200℃ | High | High temperature furnace, heat treatment |

| 430 | Medium (air) | ≤800℃ | Low | Construction, low-cost screening |

| 201/202 | Weak | ≤400℃ | Very Low | Interior decoration, low-end products |

Roll of Crimped wire mesh

5mm Stainless Steel Knitted Wire Mesh

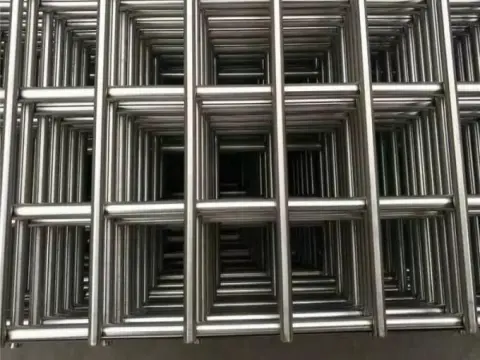

Welded Mesh Panels and Grills

Characteristics

1. Acid and alkali resistance: stainless steel material itself has higher corrosion resistance than other common metals, fearless of acid, alkali, and other harsh environments.

2. Heat resistance: high temperature resistance of 800 degrees Celsius; able to maintain stable performance in high temperature environments, without deformation or melting. Such as industrial furnaces, high-temperature filtration applications.

3. High strength and toughness: high tensile strength and abrasion resistance enable it to withstand large external forces without fracture.

4. Stable filtration performance: stainless steel metal mesh mesh and, mesh precision, stable filtration performance, suitable for a variety of filtration and separation occasions.

5. Smooth surface: uniform thickness, good filtration performance, and cleaning performance, not easy to adsorb impurities and dirt, easy to clean and maintain, but also to reduce the resistance of the fluid through.

6. Durable Protection: No maintenance is required to provide rugged protection against rust and corrosion, anti-static, ensuring long-lasting performance in a variety of applications.

7. Easy to install: With an easy-to-assemble design, our screens are simple to install and can be set up quickly and efficiently, meeting the requirements of customers looking for a hassle-free solution.

8. Wide range of uses: including animal enclosures, filtration and sieving, food and chemical, and medical and healthcare fields.

9. Quality materials: We utilize SS304, SS304L, SS316 and SS316L to ensure outstanding strength, corrosion resistance and long service life.

10. Customazible: We offer a range of customization options, including cutouts and a variety of hole shapes to meet the specific needs of our customers, whether it’s for a large project or a small-scale application.

China 304SS Stainless Steel Wire Mesh Cloth

2mm stainless steel welded mesh

4mesh-stainless-steel-wire-mesh

Type and process

Classification by processing technology

1. Woven SS mesh: Through the warp and weft yarns interwoven according to a specific rule (such as plain weave, twill, Dutch weave, ginning weave, etc.), a continuous mesh structure is formed, which can achieve high mesh count and filtering accuracy to the micron level. The mesh surface is soft and has a certain ductility, and can be bent or wound.

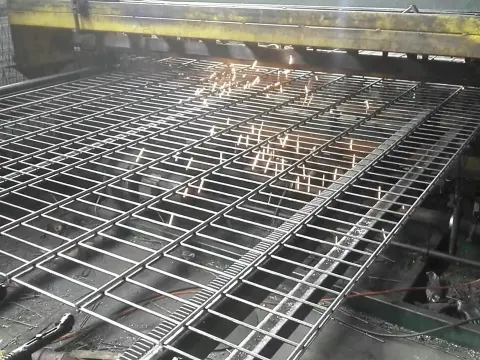

2. Welded SS mesh: The stainless steel wires are arranged in a grid layout and fixed at the intersection by resistance welding, argon arc welding and other processes to form a rigid mesh surface. The structure is rigid and not easy to deform. The filtering accuracy is at the millimeter level, the mesh is relatively large, and the tensile and impact resistance are more outstanding.

Mesh woven styles

Classification by function and use

1. Filter mesh: fine screening (medicine, water treatment), typical specifications: 100-500 mesh, wire diameter 0.02-0.1mm. Protective net: mechanical protection, building fence, typical specifications: 1-20 mesh, wire diameter 0.5-3.0mm.

2. Decorative net: building curtain wall, interior design. Surface treatment: electrolytic polishing, color coating and other methods.

3. Electromagnetic shielding net: electronic equipment anti-interference. Generally, 316L material is used, taking advantage of its low magnetic permeability.

4. High temperature mesh: resistant to high temperatures above 1000℃ (industrial furnaces, burners), commonly used materials: 310S/314.

Mesh Comparison

Classification by surface treatment

1. Ordinary type: original surface, economical and practical, cost-effective, general type.

2. Electrolytic polishing: mirror effect, easy to clean (food, medical industry).

3. Plating treatment: nickel plating and zinc plating to further enhance corrosion resistance, but this process is rarely used.

4. Coating treatment: PTFE/PVC coating (acid and alkali resistant, insulation), corrosion resistance + UV resistance double rust prevention.

Stainless steel grille welding

Mesh Panel Welding

Stainless steel wire weave

Areas of application

1. Mining: used to screen ores, coal, and other materials.

2. Construction: screening sand, stone, and other aggregates to ensure that the aggregate particle size meets the construction requirements.

3. Chemical industry: used for filtering liquids, gases, and other media, and as a lining or protective layer of chemical equipment. Filtering materials in the reaction kettle, petroleum refining filtering lubricating oil, fuel oil, and so on.

4. Metallurgy: sieving metal powder and particles to improve precision and facilitate refining.

5. Food: used in the food processing process of filtering juice and syrup, separation and packaging, and so on.

6. Pharmaceutical: used for filtration, separation, and purification in the pharmaceutical process.

7. Electronics: shielding nets and filters for electronic components.

8. Protective fences: safety nets for construction sites, barrier fences on both sides of roads, and protective fences for airports and prisons.

9. Aerospace: fuel filtration, air filtration, and other systems for aircraft engines.

10. Environmental protection field: filter mesh in sewage treatment, filter material in exhaust gas purification.

Kitchenware Spoon

isolation cage

Stainless Steel Welded Wire Mesh Panels

Selection Guide

When you buy stainless steel metal mesh, you need to pay attention to the following points:

1. Material selection: 316 is more corrosion-resistant than 304, so you need to determine the environment in which it will be used before selecting the appropriate grade.

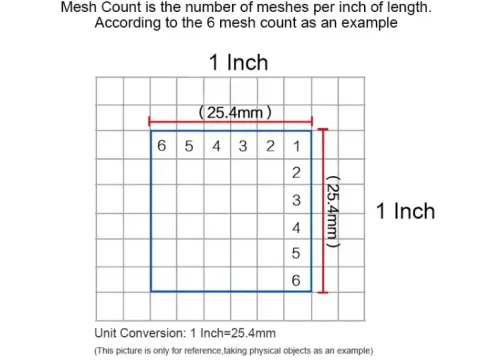

2. Mesh size: it is still necessary to choose the right size of mesh and mesh size according to your needs, which will help it give full play to its advantages.

3. Manufacturing process: choosing woven wire mesh or welded wire mesh depends on what you are using it for, both are corrosion-resistant but with different hardness.

4. Supplier reputation: choose a supplier with a good reputation to ensure product quality and after-sales service.

Mesh calculation diagram

Maintenance

1. Its integrity needs to be checked regularly, and it should be replaced or repaired in time if it is broken or corroded.

2. Regularly clean the dust and dirt on the surface of the mesh to maintain its good filtration and protection performance.

3. For stainless steel metal mesh used in harsh environments for a long time, regular anti-corrosion treatment is also needed to extend its service life.

Stainless steel wire mesh price

1. The price of stainless steel wire mesh is determined by the material, specification, weaving method, application, order quantity, and market supply and demand, 304 and 316 are the more common materials.

2. In addition to this, there are 302, 201, 304, 304L, 316, 316L, etc.; the better the material, the higher the price.

3. Furthermore, the specification parameters include the mesh, wire diameter, and aperture, the larger the specification, the price will be increased accordingly, and the size of the order, and product quality advantages and disadvantages, will affect the unit price/ton.

Stainless-Steel-Welded Panel-Reinforcement

wanzhi steel QC department

fine-aluminium-mesh-roll

Stainless steel wire mesh manufacturer -Wanzhi Steel

Why choose us?

1. Production scale: 20 fully automatic high-speed weaving production lines, with a monthly production capacity of 500,000 square meters and an annual output of more than 6 million square meters.

2. Equipment configuration: imported high-speed precision weaving machines, automatic control systems, precision testing instruments, fully automatic laser cutting equipment.

3. Technology: mastering a variety of weaving processes such as plain weave, twill weave, dense weave, etc., and can produce products with a full range of wire diameters and mesh counts.

4. Service capabilities: support batch customization, export growth of more than 20% for 5 consecutive years, 24-hour online consultation, professional technical team, perfect after-sales, quality commitment guarantee.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. We specialize in the production of SS welded wire mesh, SS Chain Link Mesh, Garden Wire Mesh, Chicken Wire Mesh, Hexagonal Wire Mesh, stainless steel rope mesh, Crimped Wire Mesh, Stainless steel mesh roll, and Perforated Stainless Steel Mesh for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message