Stainless Steel Rope Net

Stainless steel rope net is a flexible protective net made of high-quality stainless steel wire (such as 304, 316) through weaving or twisting process, with corrosion resistance, high strength, lightweight, beautiful, and environmentally friendly as the core features. It is widely used in stairs, building exterior wall decoration, horizontal or vertical fall protection, partitions, exterior wall cladding, zoos, safety nets, suspension bridges, etc. Wanzhi Steel specializes in the production of various grades of stainless steel rope nets, including 304, 316, 430, and other materials. We accept customization of rope diameter and mesh size. If you are interested, please contact us to learn more.

anti falling flexible rope net

High Strength 316 7X7 Flexible Diamond

steel rope mesh bag

Common ways to express grades

1) SS 304/316

SS is short for Stainless Steel. “SS304” is “Stainless Steel 304”.

2) AISI 304/316

This means stainless steel meets US ASTM standards.

3) SUS 304/316

SUS is the Japanese stainless steel grade, equivalent to AISI, and their standards are the same.

Features

1. High strength and impact resistance: The diameter of the single wire and the density of the rope net can be customized according to the needs. It can withstand large tension and impact force, and it is not easy to break even if it encounters external force collision.

2. Strong corrosion resistance: It uses 304, 316, and other stainless steels, contains nickel and chromium elements, and the surface is polished and passivated. The dense oxide protective film can resist corrosive environments such as moisture, salt spray, acid and alkali, and the service life is more than 20 years.

3. Flexibility and adaptability: It can be bent or cut according to the terrain, has a certain elasticity, and has a lightweight design. It can adapt to the installation requirements of irregular sites. There is no need to strictly level the foundation, and the installation is flexible and convenient.

4. Convenient transportation: It can be folded and rolled, which is convenient for long-distance transportation and rapid on-site deployment.

5. Light and breathable: The light transmittance is as high as 70% or more, light and air are not blocked, the field of vision is not blocked, and it can blend naturally with the environment.

Bridge Construction Safety Rope Wire Mesh

stainless steel sleeveless wire Cable Mesh

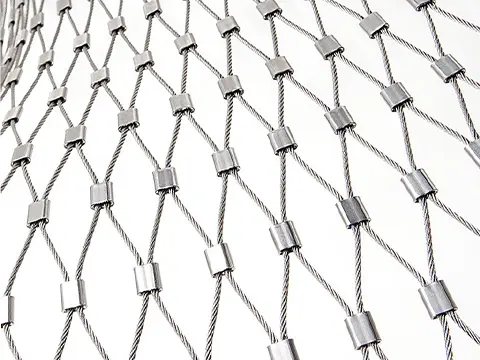

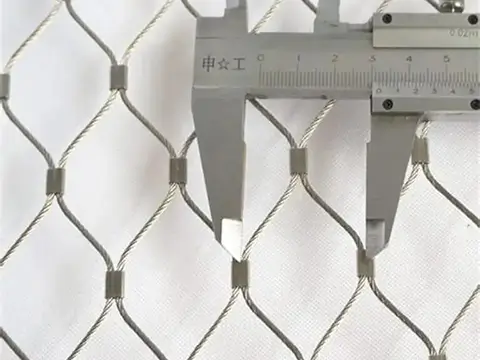

Stainless steel cable ferrule mesh

6. Aesthetics: The surface is smooth and the color can be customized, such as black, gray, and red, which blends with the use environment without destroying the overall vision.

7. High and low temperature resistance: It can be used for a long time in an environment of -50℃ to +600℃, and can adapt to extreme climate conditions, such as Arctic research stations and desert areas.

8. Easy to maintain and clean: It can be kept clean by washing with rainwater. No need for anti-corrosion treatment or frequent replacement, and it is cost-effective for long-term use. Low cost for long-term use.

9. High safety: The material has no sharp edges and the edges are rounded to avoid accidental injuries to people and animals, especially suitable for zoos and children’s activity areas.

Differences in stainless steel materials

Chemical Composition (%) of 304/316

| Steel Grade | C | Si | Mn | P | S | Cr | Ni | Mo | others |

| 304 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 18.0-20.0 | 8.0-12.0 | — | |

| 304L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 18.0-20.0 | 8.0-12.0 | — | |

| 316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 16.0-18.0 | 10.0-14.0 | 2-3 | — |

| 316L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 16.0-18.0 | 10.0-14.0 | 2-3 | — |

Scenic area corridor protection net

Deck railing guardrail

High altitude protection in rainy and snowy areas

Applications

1. Construction and safety

1) High-altitude anti-fall net: In construction sites, bridge construction, high-altitude operations and other scenes, it is used as an anti-fall barrier to effectively intercept falling objects.

2) Balcony/stairs/window protection: installed on the edge of the building to prevent accidental falls, and the patio protection net prevents falling.

3)Structural reinforcement: used for the reinforcement of reinforced concrete beams, slabs, and columns to improve bearing capacity and ductility.

2. Industry and logistics

1) Workshop isolation: divide production areas or equipment protection to prevent people from entering by mistake, and protect equipment from collisions.

2) Logistics warehousing network: divide storage areas to prevent goods from falling or people from entering by mistake, and improve warehouse management efficiency.

3. Transportation and infrastructure

1) Bridge protection net: as a protective barrier on both sides of the bridge, it prevents pedestrians or vehicles from falling, and at the same time acts as a rockfall net to resist the impact of wind, snow, and falling rocks.

2) Mountain slope protection net: reinforce the slope and rock surface to prevent rockfall, mudslides, landslides, and protect the safety of the roads or villages below.

Road Fence Protection

Zoo Mesh

Architectural Cable Safety Mesh

4. Sports and entertainment facilities

1) Sports stadium fences: such as around football fields and basketball courts, prevent people from entering and exiting at will, and prevent balls from flying out and accidentally injuring.

2) Playground protection net: surround amusement facilities such as roller coasters, slides, and trampolines to ensure the safety of tourists and prevent accidental falls.

5. Animal protection and park management

1) Zoo fence: encloses tigers, lions and beasts, giraffes and herbivorous areas, bird areas, etc., to ensure the safety of the park and allow tourists to have a clear view.

2)Aquaculture: Fence nets in seawater aquaculture areas prevent the escape of aquaculture or invasion of natural enemies, and withstand corrosion caused by long-term immersion in seawater. It is easy to distinguish and manage,

3)Pasture fence: suitable for farms, zoo free-range areas, cages, migration channels and other scenes, taking into account safety and ecological coordination.

6. Special environment applications

1) Extreme climate protection: The functions of extreme environments such as Arctic research stations and desert areas are not restricted, and the performance is stable in the range of -40℃ to 800℃.

2) Event security: quickly build temporary fences to control the flow of people at concerts, sports events, etc.

3)Disaster relief: As a temporary protection net, it is used for reinforcing ruins after earthquakes and floods, isolating dangerous areas, and maintaining shelters.

Cable Mesh for Balustrade

Rock netting slope protection

Fall arrest rope net for floors

Colored stainless steel rope net process

We can realize colored stainless steel rope net through two major processes: surface coloring treatment and artistic processing, combined with chemical, physical and printing technology.

1. Chemical coloring method

The stainless steel rope net is soaked in a heated, concentrated chromium sulfate solution, and a transparent or colored oxide film is formed on the surface by controlling the reaction time and temperature. This method does not rely on pigments or dyes. The color comes from the oxidation reaction between the metal and the chemical solution, and has the characteristics of corrosion resistance, wear resistance, and high temperature resistance.

2. Screen printing + etching

The acid-resistant protective film is printed on the surface of stainless steel by screen printing, and then the unprotected area is corroded by etching agents such as ferrous chloride to form a pattern or text, and finally the color is achieved by oxidation or spray painting.

3. Spray painting

Spray radiation coloring material particles on the surface of the stainless steel rope net to form a texture effect similar to pear skin, and then the color is attached by high temperature curing. This method is easy to operate and suitable for rapid mass production.

4. Electroplating coloring

A layer of metal or alloy plating, such as chromium, nickel, copper, etc., is deposited on the surface of the stainless steel rope net by electrochemical methods, and then the color is given by oxidation or dyeing. This method can achieve different gloss effects such as mirror and matte, and improve the grade of the product.

Red stainless steel rope net

Black stainless steel cable net

Yellow stainless steel rope mesh

Installation of Stainless Steel Rope Net

Preparation before installation

1. Confirm the bearing capacity of the installation surface: wall, column, and ground, and check whether there are corrosive environments such as strong wind, acid rain, salt spray, or high and low temperature conditions.

2. Tools: stainless steel clips, expansion bolts, U-shaped nails. Electric drill, wrench, level, dynamometer, safety rope. Equipped with safety helmets, gloves, and non-slip shoes.

Installation process

1. Fixed point selection and reinforcement: Use expansion bolts to fix on hard foundations such as concrete and brick walls

2. Tension control: Tension control, about 5% elongation, avoid excessive stretching. Use a dynamometer to detect the tension of the rope net. In areas with large temperature differences, the tension needs to be readjusted in spring and autumn.

3. Connection and splicing process: Use stainless steel clips to connect the rope net nodes. If multiple sections of rope nets need to be spliced, ensure that the overlapping length of the splicing is ≥20cm, and use double-row clips to fix. The edge of the rope net is treated with plastic sleeves or metal edging.

Maintenance

Daily maintenance: Avoid using acidic or abrasive cleaners. When a broken wire or loose buckle is found, replace the damaged part immediately to prevent local expansion. Equipped with safety warning.

Wire rope cable production line

stainless steel rope net

stainless steel wire rope net

Problems you may encounter in use

1 The rope net is loose or sagging

A: Insufficient tension or loose fixing points. It is necessary to readjust the tension, check and tighten all fixing points.

2 Buckle corrosion or breakage

A: Material mismatch or environmental corrosion. Replace with 316L stainless steel buckles and strengthen the sealing treatment.

3 Friction noise between the rope net and the fixing parts

It may be installed too tightly, or the contact surface may be rough. Adjust the tension and install rubber gaskets on the contact surface.

Stainless Steel Rope Net Factory – Wanzhi Steel

Stainless steel cable mesh is a lucrative investment and is ideal for many applications. Wanzhi Steel offers galvanized steel wire rope, stainless steel wire rope and plastic coated steel wire rope. There are diameter options of 1-20mm, and different structures such as 1*7, 1*19, 7*7, 6*7+FC, 7*19, and 6*12+FC, and deep processing services such as cutting and weaving are provided. Two types of cable mesh are available: Inter-woven Type, Ferrule Type.

You can also send us the application so that we can recommend it for you.

four package methods

steel rope mesh

galvanized wire rope

In addition, we also produce accessories, loops, fence posts, fence gates… If you want to know more details, please contact us now or leave a message, we will reply as soon as possible.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Stainless steel rope mesh, Stainless Steel Wire Rope, Stainless Steel Handrail Cable, PVC Coated Wire Rope, Stainless Steel Cable, Vinyl Coated Wire Rope, Stainless Wire Rope for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message