Stainless Mesh Sheet

Stainless mesh sheet is made of stainless steel wire or plate through welding, weaving, or punching. It is also known as stainless steel wire mesh. Stainless steel mesh has a wide range of uses and good durability and corrosion resistance. Wanzhi Steel has more than 300 specifications of 200/300/400 series stainless steel mesh in stock, including embossed, brushed, mirror, powder coated, frosted, sandblasting, anti-fingerprint, etc.

– Length: 0.3 m+ (Customized)

– Width: 0.1 m+ (Customized)

– Wire Dameter: 0.3-16mm

– MOQ: 220 pieces/250 rolls

– Delivery Time: 15-21 days

| Inquire Online | ✉Send Email |

Stainless steel mesh sheet Specifications

| Item | Stainless mesh sheet |

| Material | Stainless steel |

| Place of Origin | Hebei, China |

| Hole shape | Round, Square, Rectangle, Hexagon, Diamond, Slotted, Long hole |

| Type | Expanded Mesh, Welded Wire Mesh, Perforated Wire Mesh Sheet, Woven Wire Mesh |

| Mesh hole size | 20×20mm, 25×25mm, 30×30mm-100×100mm |

| Color | Silver or customized |

| Sample | Free and available |

| OEM/ODM service | Avaliable |

| Shipment | By sea |

| Package | Waterproof + Protective Plastic + Wooden Case |

| Payment | T/T 30% prepaid |

Characteristics of stainless mesh sheet

1. Corrosion resistance: Especially AISI 304, AISI 321, and AISI 316 have strong corrosion resistance even in harsh environments, unlike mild steel, so they require almost no maintenance.

2. High Strength: Stainless steel grades have excellent tensile strength and durability, and are suitable for heavy-duty applications.

3. High temperature resistance: can withstand high temperatures without losing structural integrity, making them ideal for industrial and automotive applications.

4. Flexibility: Despite its high strength, it can be easily cut, decoiling, bent, and molded.

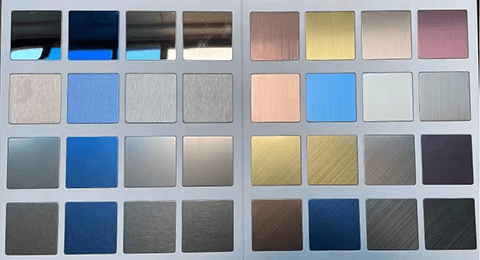

5. Aesthetics: Stainless steel mesh is available in a variety of finishes (polished, brushed, mirror, or coated).

6. Customization Options: This product offers various customization options, including different colors (silver, black, Matt black, white, red, etc.), and hole shapes (square, diamond, round, etc.).

Stainless Steel Mesh Panel Applications

Filtration and screening: water treatment, oil refining, mining, construction, and chemical industry, can filter liquids and screen classified materials.

Construction and design: protective covers for machines, fences, and railings at construction sites, and can also be used as decorative panels.

Food and beverage: used in sieves, conveyors

belts, and food processing due to its hygienic food-grade properties.

Medical and pharmaceutical: for surgical instruments, sterilization trays, and test filtration.

Agriculture: for animal enclosures, bird cages, dog cages, food troughs, and crop protection.

Automotive: for grills, filters, and exhaust systems.

Electronics: for EMI/RFI shielding and precision components.

Types of Stainless Mesh Sheet

1. Woven stainless steel mesh

1) Plain weave: The most common type, where the wires are woven in an up-and-down pattern, suitable for general filtering and screening applications.

2) Twill weave: Has a diagonal pattern, is stronger and more durable, and is used in heavy-duty applications such as mining and construction.

3) Dutch weave: Made of thicker warp and thinner weft threads tightly woven together. Ideal for fine filtration in the chemical and pharmaceutical industries.

2. Stainless steel welded mesh panels

Stainless steel wires are welded at the intersections to form a strong structure. Commonly used in fencing, animal enclosures, and architectural design.

3. Perforated stainless steel mesh sheet

The perforated panels are very strong and can be used for filtering as well as providing decorative effects, allowing light and liquid to pass through smoothly.

4. Electroformed mesh

Produced through an electroforming process, the wire diameter is fine, and the mesh is fine and extremely precise. Used in high-precision applications such as aerospace and electronics.

304 mesh sheet 6mm diameter supply

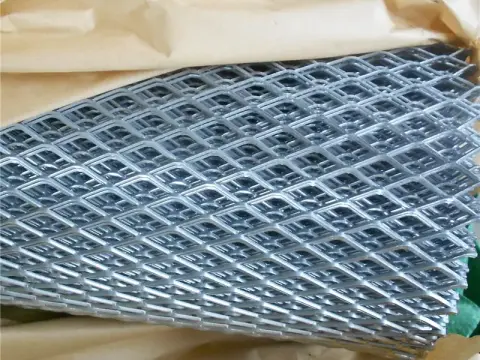

Expanded metal mesh sheet Supply

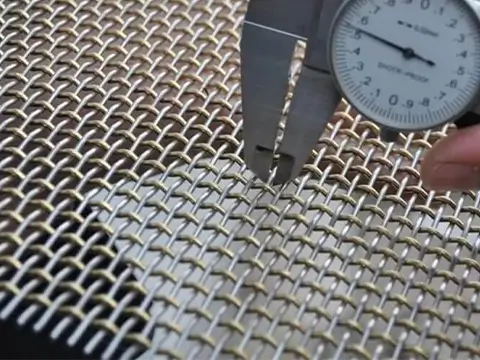

Woven mesh-diameter measurement

Chemical Composition & Mechanical Properties

1. Chemical composition

Stainless Steel is an iron-based alloy containing at least 10.5% chromium, as well as nickel (Ni), molybdenum (Mo), manganese (Mn), carbon (C), silicon (Si), sulfur (S), phosphorus (P) and other elements.

2. High temperature resistance of stainless steel

| High temperature resistance | Continuous Use Temperature | Short-term use temperature | Applicable environments |

| 304 Stainless Steel | 870°C (1600°F) | 925°C (1700°F) | Most medium to high temperature environments |

| 316 Stainless Steel | 870°C (1600°F) | 925°C (1700°F) | Food processing and chemical equipment |

| 310 Stainless Steel | 1035°C (1900°F) | 1150°C (2100°F) | Designed for high-temperature environments, for heat treatment equipment and high-temperature furnaces |

| 430 Stainless Steel | 815°C (1500°F) | 870°C (1600°F) | Suitable for medium temperature environments, household appliances and decorative sheet metal coils. |

3. Tensile Strength & Yield Strength & Hardness

| Tensile strength | Yielding strength | Rockwell hardness (HRC) (annealed condition) | Brinell hardness (HB) | |

| 304 Stainless Steel | 515-620 MPa(75,000-90,000 psi) | 205 MPa(30,000 psi) | 70-90 HRB | 170-200 HB |

| 316 Stainless Steel | 515-690 MPa(75,000-100,000 psi) | 205 MPa(30,000 psi) | 70-90 HRB | 170-200 HB |

| 310 Stainless Steel | 520-720 MPa(75,000-105,000 psi) | 205 MPa(30,000 psi) | 80-95 HRB | 180-220 HB |

| 430 Stainless Steel | 450-600 MPa(65,000-87,000 psi) | 310 MPa(45,000 psi) | 85-95 HRB | 180-220 HB |

Among them, cold rolling and cold drawing can improve the hardness and strength of stainless steel, but will reduce the ductility; annealing, and quenching can change the mechanical properties of stainless steel; chromium (Cr), nickel (Ni), molybdenum (Mo) and other elements of the content affects the other characteristics.

Production Process

Perforated mesh sheet: stainless steel plate → perforated according to the size and shape of the drawing.

Woven mesh sheet: stainless steel wire → woven by a weaving machine according to the mesh number.

Welded mesh sheet: stainless steel wire → cross-welded by a welding machine.

14, 16, 18, 20, 24 Ss Steel 2B Finish Sheet

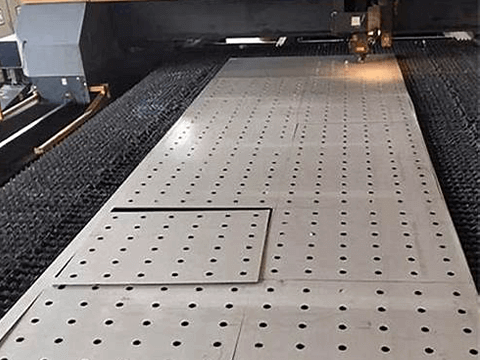

Thin plate perforation production

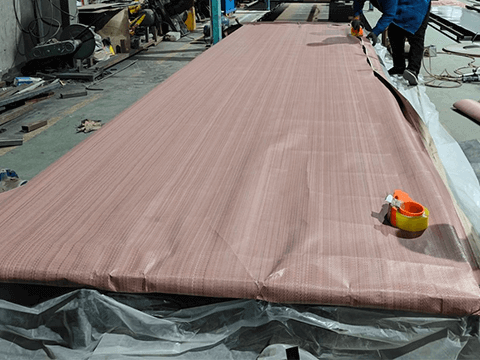

Weaving by mesh

Stainless wire mesh sheet Packaging Method

Wanzhi Steel uses plastic film + kraft paper to pack the inside, the edges are protected with foam or cardboard, multiple mesh sheets are stacked on pallets and fixed with straps, and wooden crates are optional for large or heavy-duty mesh sheets.

heavy duty stainless expanded metal 4×8

inner package

Woven mesh sheet packaging

Price of stainless steel wire mesh sheets

The price of an ss mesh sheet mainly depends on the stainless steel grade, mesh size and wire diameter, and surface treatment.

Price range:

– Standard plain weave mesh: $10-50 per square meter.

– Dutch weave or special mesh: $50-200 per square meter.

– Electroformed or high precision mesh: $200-500 per square meter.

Note: Please ask online professionals for the latest prices.

Perforated mesh hole type

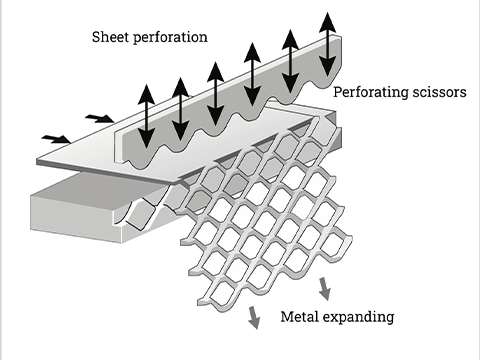

Expanded mesh Production Process

Typical surface treatment

Stainless steel mesh sheet cooperation Case

Many customers choose Wanzhi’s stainless mesh plate. We strictly control the quality and have quality inspections and audits.

At present, our products have been put into use in Türkiye’s photovoltaic power station, Russia’s Biological Research Institute, Syria’s Redemption Hospital, Argentina’s breeding and planting plant, Saudi Arabia’s garbage station, Iran’s chemical plant, etc.

Bulgaria 411 tons welded mesh project

623tons Welded mesh shipped to Moldova

Wholesale OEM Stainless Steel Insect Mesh

Stainless steel mesh sheets for sale – Wanzhi Steel

If you’re looking for a solution for heavy-duty industrial use or an elegant design element, the stainless steel net sheet is a reliable and cost-effective choice.

We have stainless steel expanded metal 4×8, 6×12, and all other sizes of welded & woven Ss mesh sheets in stock.

Popular Colors and Finishes →

Color & Finish selection Card

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of galvanized welded wire mesh, crimped wire mesh, perforated mesh sheet, SS steel woven/welded mesh sheet/roll for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message