PVC Coated Wire Rope

PVC coated wire rope is semi-flexible and widely used in various commercial and outdoor applications. Applications include safety cables, catenary systems, barrier ropes, guardrails, clotheslines, slaughterhouse wire mesh, and store display racks. For example, PVC-coated GI steel wire rope is a low-cost alternative to stainless steel wire rope. Wanzhi Steel supplies PVC-coated steel wire rope in various lengths, strands, and colors in the form of rolls, and we have stainless steel wire rope, galvanized wire rope, carbon steel wire rope, and other base materials to choose from. We also accept customized solutions. You are welcome to contact us for details.

plastic coated steel rope

plastic coated stainless steel cable

PVC Coated Wire Rope Specification

| Item | PVC Coated Wire Rope |

| Place of Origin | Hebei, China |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Application | Hoisting, lifting, drawing, towing |

| Surface treatment | Oil, Galvanized, Plastic-coated |

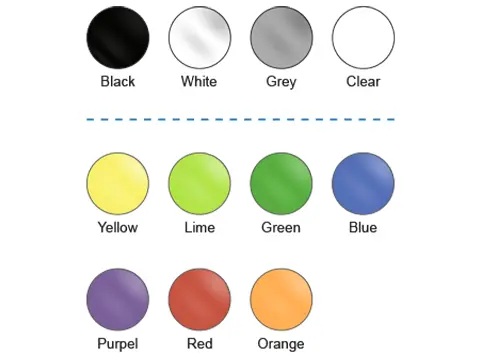

| Color | Transparent, red, white, green, blue, black, etc |

| Structure | 6*19/6*7/7*9/7*19/7*3*3/6*3*7 |

| Length of reel/coil | 100m-2000m/reel, etc |

| Other coating options | PVC/PP/PE/PU/Nylon |

| Cores | Fiber Core, Steel core ( IWRC, IWS) |

| Tensile strength | 350-550N/mm2 |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

What is PVC coated wire rope?

PVC Coated Wire Rope is a steel wire rope with a protective layer of polyvinyl chloride (PVC) on its surface. It has the strength of steel wire rope and the corrosion resistance, wear resistance and insulation of PVC. It is widely used in many fields and has a variety of diameters, structures, colors and materials. Wanzhi Steel has a large number of regular sizes in stock, welcome to learn more.

3 16 plastic coated cable

6mm pvc coated wire rope

Green PVC-coated wire rope 3mm

The core of PVC-coated wire rope

There are fiber core and wire rope core, specifically: Fiber Core (F.C.), usually polypropylene (P.C.), sometimes hemp (H.C.), and sisal. Independent Wire Rope Core (IWRC), Wire Strand Core (WSC), IWRC, and WSC are sometimes referred to as steel wire core or steel center.

PVC coated wire rope features

Are you looking for a strong, durable, abrasion and corrosion resistant steel wire rope? Then our plastic coated steel cable is exactly what you need!

- Strong corrosion resistance: PVC coating can effectively isolate steel from the external environment and improve its corrosion resistance. In harsh environments such as humidity, acid and alkali, the life of PVC coated steel wire rope is 3.5 to 5 times that of ordinary galvanized steel wire rope.

- Excellent wear resistance: In dynamic load operations such as lifting and transportation, its service life is 1.5 to 2 times that of ordinary steel wire rope, especially suitable for working conditions with frequent friction.

- Stable mechanical properties: The plastic coating process maintains the original high strength characteristics of the steel wire rope, and at the same time enhances the stability of the overall structure through the coating to meet the heavy load requirements.

- Beautiful and practical: It provides a variety of color options such as transparent white, black, yellow, green, and red to meet the aesthetics of different scenes, and the smooth coating is also easy to clean and maintain.

Galvanized Wire Rope IWRC FC

plastic coated wire cable

red plastic coated cable

- Shock absorption and anti-extrusion: The plastic coating has elastic buffering characteristics, which can effectively absorb impact and reduce the risk of breakage under dynamic load.

Fatigue resistance: The coating reduces internal stress concentration, and its durability is about 2 times that of ordinary hemp core or metal core steel wire rope, which is suitable for long-term cyclic use. - Combining economy and safety: plastic coated wire rope has moderate cost, strong comprehensive performance, wide application scenarios, and high overall cost performance.

The composition of wire rope

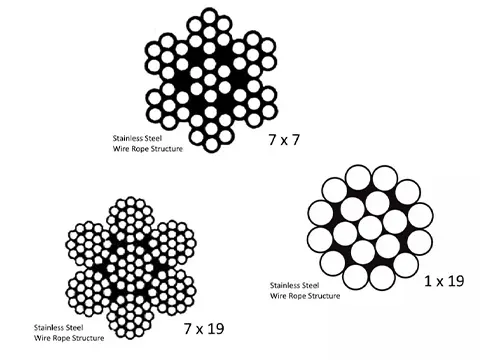

- 1×7 structure: single strand 7 wires, 1 center wire + 6 outer wires spirally wrapped, simple structure, high rigidity and tensile strength, poor bending.

- 1×19 structure: single strand 19 wires, 1 center wire + 6 middle wires + 12 outer wires. More flexible than 1×7, but still maintains high strength and better fatigue resistance than 1×7.

- 7×7 structure: 7 strands × 7 wires, 7 strands of steel wire bundles, each bundle consists of 7 steel wires, good flexibility and torsion resistance, medium load capacity.

- 7×19 structure: 7 strands × 19 wires, 7 strands of steel wire bundles, each bundle consists of 19 steel wires, extremely high flexibility, excellent fatigue resistance, suitable for frequent bending.

- 7×7+FC structure: 7×7 steel wire rope + fiber core, such as sisal or synthetic fiber. The fiber core provides additional flexibility, good shock absorption performance, and light weight.

- 7×19+IWRC structure: 7×19 steel wire rope + independent steel wire rope core. It combines extremely high strength and flexibility, has good anti-extrusion performance, and is suitable for heavy-load and high-frequency use.

- 19×7 structure: non-rotating type, with multiple layers of steel wire reversely wound to reduce rotation, and almost no rotation when loaded, suitable for vertical lifting.

steel cable structure

Wanzhi Steel Popular Colors

Commonly used plastic coatings

- PVC Coating: PVC is a low cost, general purpose coating and regularly used to cover 1X19, 7X7, and 7X19 stainless steel wire rope. PVC is a very flexible coating.

- Polypropylene Coating: This material is often chosen for its resistance to corrosion and chemical leaching, it has a resilience against most forms of physical damage, including impact and freezing.

- Nylon Coating: Nylon 11 and Nylon 12 a flexible, hard-wearing, and abrasion-resistant coatings. A superior Ideal for running applications requiring a covered wire rope.

Uses

Use in different fields

- Construction & Engineering: Lifting and traction of heavy objects during construction (such as tower cranes and cranes), safety ropes for high-altitude operations, also used as bridge cables and building structure support ropes.

- Agriculture & Fisheries: Suspension ropes for fixing fishing nets and breeding boxes in aquaculture, as fence traction ropes for pastures and farms, wear-resistant and resistant to biting. Also used as traction ropes for agricultural transmission ropes such as harvesters and roller shutters.

- Industry & Manufacturing: Towing ropes for conveyor belts and elevators, hoisting ropes for mine hoisting, metallurgical furnaces, port cranes, and containers, adapted to humid salt spray environments.

- Shipbuilding & Marine Engineering: Hull hoisting, anchor ropes, mast rigging, offshore oil platforms, submarine cable fixing ropes, adapted to harsh marine environments.

PVC coated wire lock

Hanging clothesline

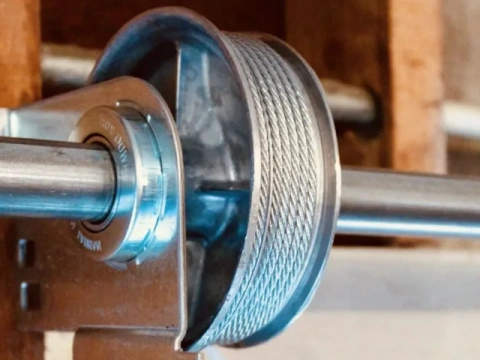

Lifting equipment traction rope

- Municipal & Gardening: Park sculpture hoisting, load-bearing ropes for outdoor landscape rope bridges, street light pole fixing, billboard hanging ropes, insulation coatings to prevent leakage and anti-aging, and fixed traction ropes for large tree transplants.

- Sports & leisure equipment: traction ropes for roller coasters and cableways, load-bearing ropes for gym pullers and climbing walls, tent fixing ropes, and traction ropes for mountaineering equipment.

- Power & communications industry: traction ropes for laying power cables and communication optical cables, support ropes for low-voltage power lines, and overhead lines.

- Home and daily use: hanging ropes for chandeliers and heavy curtains, pet fences, pet traction ropes, and clotheslines.

Different rope strands uses

- 1×7 structure: Straight cables such as fences and guardrails, which require high-rigidity fixed supports.

- 1×19 structure: Fixtures with moderate bending requirements, building support structures.

- 7×7 structure: Pulley systems, general lifting applications, occasions requiring moderate bending.

- 7×19 structure: Crane cables, ship moorings, dynamic applications requiring high flexibility.

- 7×7+FC structure: Lifting operations requiring buffering, temporary suspension systems.

- 7×19+IWRC structure: Heavy cranes, mine hoisting equipment, extreme working conditions.

- 19×7 structure: Elevator cables, tower crane wire ropes, vertical lifting requiring stability.

plastic coated wire rope

Transparent layer pulley cable

PVC Steel Wire Clothesline

Uses of different plastic coatings

- PVC Coating: Guardrail, Catenary systems, Washing lines, Abattoir wire, Security cables, Lock cable systems, Barrier ropes.

- Polypropylene Coating: Gymnasium cables, Guardrail, Catenary systems, Horticultural applications, Security cables, Lock cable systems, Barrier ropes.

- Nylon Coating: Typical applications include: Cannery lines, Gymnasium cables, Security cables, Roller shutter cables, Lock cable systems, Barrier ropes.

Plastic coated steel rope representation method

Standard structure representation method

“Wire rope structure” + “PVC coating” + “Technical parameters”, the wire rope structure is expressed in number of “strands x number” of wires.

Example:

- 6×19+IWS + PVC Coating + Ø12mm (Core: Fiber) – Breaking Load: 18kN. The explanation is as follows: 6×19+IWS: 6 strands, 19 wires per strand, IWS means independent wire rope core.

- 6 x 25: indicates that the wire rope consists of 6 strands, which in turn have 25 individual wires.

Common share counts

1×3, 1×7, 1×19, 1×37, 3×3, 3×7, 6×7, 6×19, 6×12+7fc, 6×24+7fc, 6×15+7fc, 6×37, 19×7, 6x19S, 6x19W, 6x25Fi, 6x26WS, 6×36, 6x31WS, 8x19S, 8x19W, 8x25Fi, 8×26, SW35W*K7, 35W*7, 6*K36WS, 4V*39S+5FC.

pvc coated wire rope 3mm

plastic coated rope

Translucent yellow wire rope

Production Process

- Wire rope pretreatment: Remove oil, dust, and impurities on the surface of the wire rope, and perform surface treatment (phosphating, galvanizing) to enhance the adhesion and corrosion resistance of the coating.

- PVC coating material preparation: Select the appropriate PVC resin type, such as soft or hard PVC. Add plasticizers, stabilizers, pigments and other additives to improve performance.

- Coating process: Extrusion coating, the pretreated wire rope is passed through the extruder, and the PVC melt is extruded at high temperature and evenly wrapped on the surface of the wire rope.

- Cooling and curing: The PVC coating is quickly cured through a cooling trough or cooling device to form a stable structure.

- Tractive and reeling: Reel into a roll through a traction device, and the roll weight and roll diameter must meet customer requirements for easy storage and transportation.

- Quality inspection: Check the appearance, thickness, adhesion, and other properties of the coating to ensure that the product meets the standards.

- Packaging and storage: Labeling packaging for easy identification and reasonable storage.

yellow coated wire rope

black plastic covered wire rope

PVC Coated Steel Cable vs. Other Cable Types

| Feature | PVC Coated Steel | Galvanized Steel | Stainless Steel | Nylon Rope |

| Corrosion Resistance | High (with coating) | Moderate | Very High | Low |

| Strength | Very High | High | Very High | Medium |

| Flexibility | Moderate to High | Low to Moderate | Moderate | Very High |

| Cost | Affordable | Low | Expensive | Low |

| Best For | Marine, fencing, security | General outdoor use | Extreme environments | Light-duty tasks |

How to choose the right PVC-coated steel cable?

- Determine load requirements: Check the working load limit (WLL) and breaking strength depending on the application.

- Environment of use: To prevent saltwater exposure, ensure a high-grade PVC coating. To protect against UV rays, choose UV-stabilized PVC.

- Flexibility needs: Static applications such as fencing and guardrails, recommend 1×7 or 1×19 cables, and dynamic applications such as lifting and rigging recommend 7×7 or 7×19 structures.

- Diameter and coating: The thicker the coating, the better the protection, but flexibility may be reduced.

- Color and aesthetics: Choose a color that matches the functional or decorative needs.

plastic coated wire 5mm

green pvc coated steel cable

Installation and maintenance tips

Installation practices

- Use the appropriate crimping tool for fitting connections.

- Avoid kinking during handling.

- Ensure adequate tension to prevent sagging.

Maintenance guidelines

- Regularly check the PVC layer for cuts or abrasions.

- Wash with mild soap and water to remove dirt and salt.

- When not in use, store in a cool, dry place.

FAQ

Q1: Can PVC coated steel cables be used for lifting?

A: Yes, 7×7 and 7×19 models are suitable for lifting as long as they meet the safe load rating.

Q2: What is the service life of the PVC coating?

A: If properly maintained, the service life of the PVC coating can be up to 5-10 years, depending on environmental exposure.

Q3: Is PVC coated cable UV resistant?

A: Many PVC coatings contain UV inhibitors, but long-term exposure to high temperatures may slowly degrade the coating performance.

Package

1 8 plastic coated cable

plastic coated wire rope manufacturers

PVC coated wire rope Supplier- Wanzhi Steel

Wanzhi Steel PVC coated wire cables are suitable for a wide range of applications, including lifting, securing, and hauling. Whether in construction, maritime, or any other industry, we have the perfect wire rope for the project. We supply nylon and polyvinyl chloride (also known as PVC or vinyl) coated wire ropes and aircraft cables in reel form, pre-cut lengths, or assembled into assemblies.

On special request, we can also provide coatings such as HDPE, Hytrel, and FEP.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of PVC Coated Galvanized Wire, PVC Coated Wire Rope, Stainless Wire Rope, SS Steel Handrail Cable, Vinyl Coated Wire Rope, and SS Steel Cable for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message