How Many Types Of Reinforcing Bars Are There?

We must be very familiar with Reinforcing Bars. They are the main load-bearing and structural materials of buildings. The Reinforcing Bar is steel material used for reinforced concrete and prestressed rebar mesh, and their cross-section is round. We often see many kinds of steel bars, some are silver-white, some are gray, some are green, furthermore, some are stacked in bundles, some are packaged in rolls, and some are curved. In addition, some are ribbed, while others are very smooth. The diameters of the steel bars in the manholes and around the poles are also different. What are they classified according to? Next, let’s take a closer look at the types, grades, and codes of steel bars.

rebar for sale

rebar rods

How Many Types Of Reinforcing Bars Are There?

There are many ways to classify Reinforcing Bar, which can be summarized into the following seven categories:

Ⅰ. Classification by production process

1. Hot-rolled steel bars: Finished steel bars that are formed by hot rolling and naturally cooled. They are a type of common steel bars used in concrete structures. There are two types of surface shapes: smooth round steel bars and crescent rib steel bars.

2. Cold-rolled steel bars: Steel bars processed by cold rolling.

3. Cold-drawn steel bars: Steel bars are processed by cold drawing.

4. Heat-treated steel bars: Made by heat treatment of Grade IV steel bars, with higher strength than the former.

Ⅱ. Classification by strength level

1. HPB series: hot-rolled round steel bars, mainly made of low-carbon steel with low strength grades, such as HPB235, HPB300, etc. This type of steel bar is mainly used in places where the structural requirements are not high, such as stirrups and tension bars.

2. HRB series: hot-rolled ribbed steel bars, made of medium-carbon steel or low-alloy steel, with high strength grades, such as HRB335, HRB400, HRB500, etc. This type of steel bar is widely used in various building structures, especially in places where large tensile forces are required.

Ⅲ. Classification by chemical composition

1. Carbon steel rebar: a rebar made of steel with carbon as the main alloying element.

2. Ordinary low alloy steel rebar: a rebar made of carbon steel with a small amount of alloying elements added.

3. Stainless steel rebar: mainly made of stainless steel, with excellent corrosion resistance and high temperature resistance. Often used in places where long-term exposure to harsh environments is required.

4. Galvanized rebar: refers to a rebar with a zinc layer formed by continuous hot-dip galvanizing on the surface of the rebar to enhance its durability and corrosion resistance.

Deformed Bar Coils

Deformed Bars

Ⅳ. Classification by mechanical properties

1. Grade I steel bars (Grade 300/420): lower strength but better ductility.

2. Grade II steel bars (Grade 335/455): higher strength and better ductility.

3. Grade III steel bars (Grade 400/540): higher strength but relatively poor ductility.

4. Grade IV steel bars (Grade 500/630): highest strength and worst ductility.

Ⅴ. Classification by rolling shape

1. Smooth steel bar: steel bar with a smooth surface, usually used for Grade I steel bar.

2. Deformed steel bar: steel bar with ribs on the surface, usually with 2 longitudinal ribs and evenly distributed transverse ribs along the length direction. The shape of the transverse ribs is spiral, herringbone, and crescent. Deformed steel bar has a stronger bonding ability with concrete and can better withstand external forces, so it is mostly used in construction.

VI. Classification by supply method

1. Coiled round steel bars: Steel bars are supplied in the form of coils. Because steel bars with a diameter of less than 10 mm are easy to bend, they are coiled into circles to reduce their length during transportation. They are usually used for small building structures or raw materials before steel bar processing.

2. Straight steel bars: Steel bars are supplied in the form of straight bars, which are suitable for large building structures or occasions where direct use is required. And its size range is wide.

Plain Round Bar

Concrete Reinforcing Bar

Epoxy Coated Rebars

Ⅶ. Classification by role in the structure

1. Tension bars: steel bars that bear tensile and compressive stresses and are the main load-bearing components in the structure.

2. Hoop bars: bear part of the diagonal tensile stress and fix the position of the tension bars, and mostly used in beams and columns.

3. Frame bars: used to fix the position of the steel hoops in the beam, forming the steel skeleton in the beam, usually set on both sides of the outer edge of the compression zone of the beam.

4. Distribution bars: used in roof panels and floor slabs, arranged vertically with the tension bars of the slabs, evenly transferring the weight to the tension bars, fixing the position of the tension bars, and resisting the temperature deformation caused by thermal expansion and contraction.

5. Other structural bars: such as waist bars, embedded anchor bars, and prestressed bars, etc., are configured according to the structural requirements of the components or the needs of construction and installation.

Examples of common types of Reinforcing Bars

1. Q235: A common carbon structural steel with good plasticity and weldability, commonly used in the manufacture of steel bars, bolts, etc.

2. 20MnSi: A low-alloy high-strength steel with high strength and toughness, commonly used in the manufacture of important structural parts.

3. 304 stainless steel: A common stainless steel material with excellent corrosion resistance and high temperature resistance, commonly used in the manufacture of stainless steel bars.

Meaning Of Reinforcing Bars Grade & Codes

We often see some steel bar grades on drawings, such as HPB300, HRB335, HRBF400, and RRB400. So what do the letters and numbers here mean? Please continue reading.

H: hot rolled

C: cold rolled

R: ribbed bar

P: plain round bar

B: short for steel bar

F: fine grain

E: seismic ductility

Number: minimum yield strength

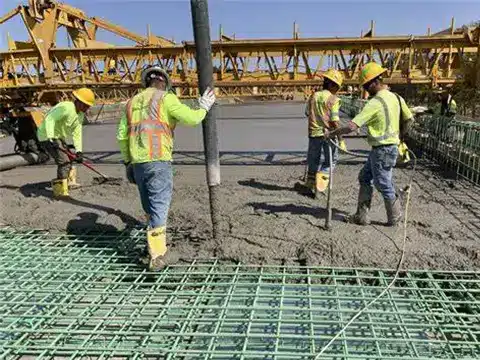

Foundation

steel reinforcement bars

Bridge

Brand Chart Of Reinforcing Bars

Table 1.

| Brand | Nominal diameter d(mm) | Yield strength standard value | Ultimate strength standard value | Application |

| HPB300 (grade 1 steel) | 6-14 | 300 | 420 | 1. Ordinary longitudinal force-bearing steel bars should be HRB400/HRB500/HRBF400/HRBF500, and HPB300/HRB335/HBF35/RRB400 steel bars can also be used;

2. Ordinary longitudinal force-bearing steel bars of beams and columns should be HRB400/HRB500/HRBF400, as well as HRBF500 steel bars; 3. Stirrups should be HRB400/HRBF400/HPB300/HRB500/HRBF500 steel bars; HRB335/HRBF335 steel bars can also be used. |

| HRB335 (grade 2 steel) | 6-14 | 335 | 455 | |

| HRBF335 (grade 2 steel) | 6-50 | 400 | 540 | |

| HRB400 (grade 3 steel) | 6-50 | 500 | 630 |

Note: When using steel strands with a standard ultimate strength of 1960N/mm² as post-tensioned prestressed reinforcement, reliable engineering experience should be available.

Therefore, it can be seen from the above table. The number of the grade refers to the yield strength. In fact, the steel bar also has an ultimate strength, which is the tensile force at which the steel bar is just broken. In other words, the force on the steel bar in the component must not be greater than the ultimate strength. If it is greater than the ultimate strength, the steel bar will be broken.

Moreover, for more about Reinforcing bar grades and codes, please browse this article – Steel Rebar Size, Grades & Codes.

Table 2. Design values of ordinary Reinforcing Bars strength (N/mm²)

| Brand | Design value of tensile strength | The design value of compressive strength |

| HPB300 | 270 | 270 |

| HRB335 | 300 | 300 |

| HRB400/HRBF400/RRB400 | 360 | 360 |

| HRB500/HRBF500 | 435 | 435 |

Reinforcement Bar Rolls

the transportation of rebar

Reinforcing Bar Quality Supplier – Wanzhi Steel

Wanzhi Steel Factory is located in Boxing County, Shandong Province. It is an independent manufacturer and supplier. Over the years, we have developed a multilingual sales team. Our products are of excellent quality and have been exported to more than 100 countries.

Furthermore, we have become long-term partners with customers in many countries and have rich export experience. Besides, we accept all customized sizes.

Main products: GI Flat Bar, Steel Round Bar, , GI Concrete Mesh, and Galvanised Welded Mesh Panel.

Furthermore, Galvanized Steel Grating, as well as Steel Reinforcement Mesh are also available on sale.

WANT A QUOTE?

![]() Whatsapp CHAT DIRECTLY / EMAIL DIRECTLY

Whatsapp CHAT DIRECTLY / EMAIL DIRECTLY

Leave Us A Message