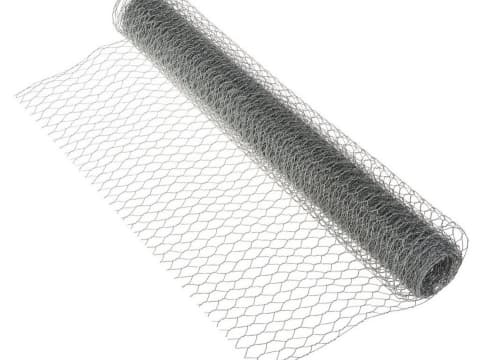

Galvanized Steel Stucco Netting

Wire Diameter: 20ga,17ga, 16ga, etc. (2.0-4.0mm)

Hole Shape: Hexagonal

Surface Treatment: Galvanized

Galvanized Steel Stucco Netting

Galvanized steel stucco netting is a common application form of galvanized steel wire mesh in plaster construction. It’s mainly used for building stucco walls, adhering bricks, isolating rodents, floor foundation mats, and wall repair reinforcement mats. Since it is woven with galvanized steel wire, it can reduce rust and corrosion over time. At Wanzhi Steel, there are many sizes of stucco netting for you to choose from, and we also accept customization of size and color. For bulk orders, factory prices will be provided, and you are welcome to send us your requirements.

steel stucco netting

steel stucco netting

Galvanized Steel Stucco Netting Specification

| Item | Galvanized Steel Stucco Netting |

| Place of Origin | Hebei, China |

| Delivery Time | 15-21 days |

| Steel Grade | Q195/Q235/SAE1006/SAE1008 |

| Color | Silver |

| Keywords | Stucco wire mesh, expanded metal lath, and Stucco diamond wire mesh for wall plastering |

| Weight | 1.75lb/2.5lb/3.4lb |

| Mesh Opening | 1” 1/4” |

| Type | Woven mesh, welded mesh |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Payment term | TT 30% Advance + 70% Balance |

| Sample | Free Available |

| Price Item | FOB, CIF, EXW, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 Tons, 220 rolls |

| Transportation | By sea, by land |

| Application | Wall plastering, insulation system reinforcement, tile base treatment |

What is Galvanized Stucco Netting?

Galvanized Steel Wire Plaster Mesh is a mesh building material made of galvanized wire woven or welded. Mainly used for the reinforcement of wall plastering projects. It can enhance the strength and durability of the plaster layer, prevent cracking, and thus improve the overall quality of the building. It has excellent corrosion resistance, strength, and rust resistance, can extend the service life of the building, and is an essential material for basic construction.

stucco net production

17 gauge stucco netting

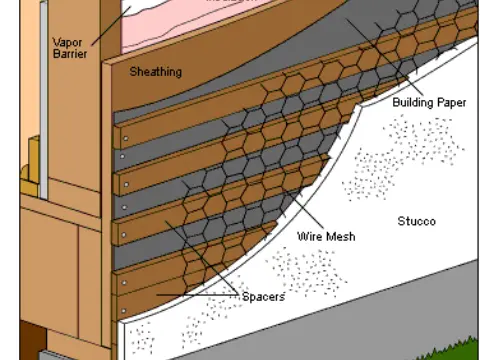

What is the metal under stucco called?

It is called metal lath, available in the form of steel plates or wire mesh, provides a lightweight, easy-to-install and construct base or pad for construction applications, which can help reinforce and enhance overall stability.

When to use stucco netting?

Stucco wire mesh is typically installed over a building to provide a stable surface for the application of stucco. It helps to strengthen the stucco and prevent cracking by distributing the forces exerted on the wall surface more evenly.

Galvanized Steel Stucco Netting Features

- Strong corrosion resistance: The galvanized treatment covers the surface of the steel wire with a layer of zinc, which can effectively prevent oxidation and corrosion of the steel wire and extend its service life. It can be used in humid environments or on building surfaces exposed to the outside for a long time.

- Stable structure: It is woven or welded from high-strength steel wire, with high tensile strength and impact resistance. It can effectively disperse wall stress, prevent cracking, and improve stability.

- High construction adaptability: The mesh is uniform, which facilitates the penetration and bonding of plaster or mortar, and enhances the adhesion between the plaster layer and the base layer. Good flexibility, adaptable to complex needs.

- Economical and practical: The cost is low, the construction efficiency is high, and the construction period can be shortened. Its durability also reduces the frequency of later repairs and replacements, and it is cost-effective.

stucco-siding-diagram

k lath stucco netting

Where is Galvanized Steel Stucco Netting Used?

- Wall crack prevention and reinforcement: used for interior and exterior wall plastering layers, suitable for the joints between new and old walls, and the interface between different materials (such as brick walls and concrete walls) to reduce cracks caused by stress concentration.

- Insulation reinforcement system: used as a reinforcement layer in the exterior wall insulation system to improve the bonding strength between the insulation board and the plastering mortar to prevent the insulation layer from falling off.

- Ceiling and partition reinforcement: used for light steel keel ceilings or partition walls, suitable for commercial spaces, residential areas and other places with high requirements for flatness.

- Special environment: used for protection of buildings with high durability requirements in humid areas (such as toilets, basements) or coastal high salt fog areas such as industrial plants, warehouses, etc.

- Old wall renovation and reinforcement: used for renovation of old walls, repairing cracks by hanging mesh plastering, such as historical building protection or old community renovation projects.

- Decorative base treatment: used as a base reinforcement layer for tile and stone wall decoration, used in public buildings, high-end residences, and other scenes with high requirements for decorative effects.

stucco wire netting

galvanized stucco netting

Stucco wire mesh in construction

Lifespan & Preventive Measures

Lifespan

The service life of galvanized steel plaster mesh is usually between 10 and 30 years, but this range is not absolute because it is affected by many factors, such as the quality and thickness of the galvanized layer, whether it is in a dry, well-ventilated environment or a humid, rainy or corrosive gas-rich environment, and whether it is in static use or frequently scratched or subjected to high stress during use.

Preventive Measures

- When choosing galvanized stucco wire lath, the appropriate specifications and parameters should be selected according to the specific project requirements.

- During the construction process, it should be ensured that the plastering mesh fits tightly against the wall to avoid hollowing, falling off, etc.

- Steel stucco netting should be stored in a dry and ventilated environment to avoid moisture and corrosion.

17 Gauge Wire Stucco Netting

paperback stucco netting roll

Reinforced expanded metal laths

Manufacturing Process

1. Raw material preparation

Select high-quality low-carbon steel wire (Q195/Q235) and cold-draw it to the target diameter (usually 0.5-1.2mm).

2. Welding/weaving forming

- Welded mesh: The cross points of the steel wire are welded by a resistance welding machine to form a square mesh, usually 10mm×10mm or 20mm×20mm.

- Woven mesh: Hexagonal mesh, automatically woven into a honeycomb structure, with better flexibility.

3. Galvanizing

- Hot-dip galvanizing: The mesh roll is immersed in molten zinc liquid to form a uniform anti-corrosion layer.

- Electroplating: Galvanizing is carried out in an electrolyte by chemical deposition, and the zinc layer is relatively thin.

4. Post-processing

- PVC/polyester coating: optional, enhances alkali resistance, suitable for high humidity environment.

- Leveling and cutting: Cut into rolls (1m×50m) or sheets (1m×2m) after flattening.

5. Quality inspection and packaging

Use magnetic thickness gauge to test zinc layer thickness, salt spray test to test corrosion resistance, and test galvanized wire and solder joint tensile strength. Wrap with moisture-proof paper and tie with steel frame or wire.

Metal Wire Rod Wanzhi facroty

Stainless steel wire production line

Production Line

Price of Galvanized Steel Stucco Netting

The price of galvanized steel mortar mesh is mainly affected by the following factors:

1. Raw material cost: steel price fluctuations (especially zinc ingots and low carbon steel), zinc layer thickness (Z60/Z100 and other specifications).

2. Production process: welding process (resistance welding cost is lower than weaving process), surface treatment, ordinary galvanizing price < PVC coating.

3. Specification parameters: mesh density (10mm mesh is 15-25% more expensive than 20mm), wire diameter (0.8mm is about 30% more expensive than 0.5mm)

4. Total order volume: Large orders or bulk orders can enjoy bulk discounts on the basis of factory prices.

Wanzhi Steel provides a real-time raw material price linkage quotation mechanism, which is updated in time to ensure transparent and reasonable prices. To know today’s prices, please contact professional technicians.

1.75lbs 2.5lbs 3.4lbs GI Steel Stucco Netting

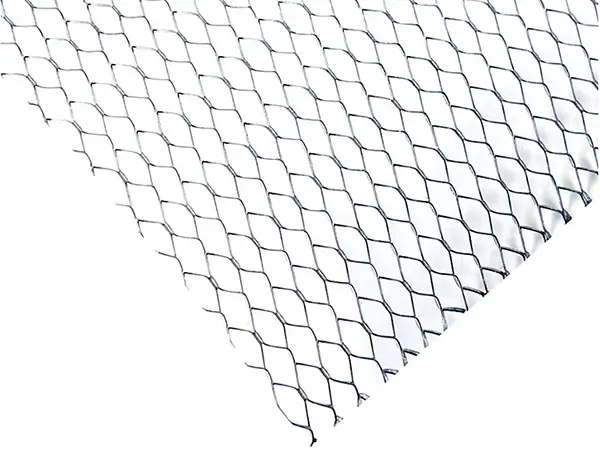

Diamond Stucco Mesh

Galvanized Stucco Netting Factory- Wanzhi Steel

In summary, Galvanized Steel Stucco Mesh is a superior, economical, and practical building material that plays an important role in plastering projects. It is necessary to choose a reputable supplier, and Wanzhi Steel will be able to meet your various size requirements. We have developed a very mature multilingual sales team and have rich export experience. If you want to know the specifications and prices of the products, you can contact us at any time.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 90001 certified factory located in Hebei, China. It specializes in the production of Gi expanded metal mesh, Galvanized Steel Stucco Netting, expanded metal lath, Welded Wire Mesh, Expanded Metal Grating, Diamond Mesh Lath, and Galvanized Woven Wire Mesh. Its monthly output is 2,000 tons. With high-quality products and superior services, its products have been exported to more than 120 countries around the world.

Leave Us A Message