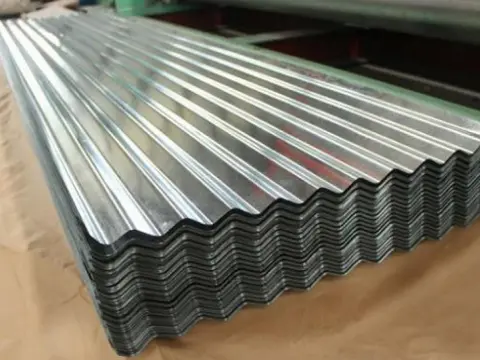

Galvanized Roofing Sheets

Galvanized roofing sheets are a roofing material made from cold-rolled steel sheets, hot-dip galvanized or electroplated. The zinc layer isolates air and moisture, significantly improving corrosion resistance and extending service life. Its high strength, ease of construction, and excellent cost-effectiveness make it widely used in industrial plants, warehouses, logistics centers, and other structures. It is also suitable for waterproofing and load-bearing roofing in some residential buildings. As a professional manufacturer, Wanzhi Steel offers galvanized roof panels with different zinc coatings, thicknesses, and widths. We also provide value-added services such as welding, cutting, perforating… If you are interested, please contact us.

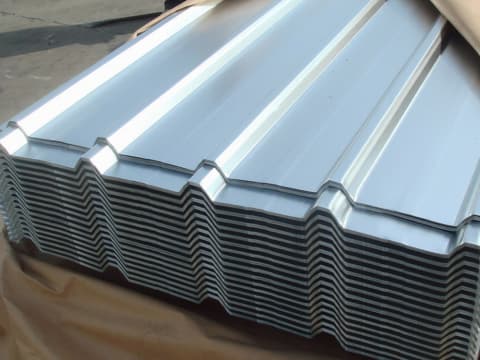

Spangle Galvanized Roofing Gi Sheets

galvanized corrugated steel

Specification

| Item | Galvanized Roofing Sheets |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Delivery Time | 8-14 days |

| Zinc Coating | 30-275g/m2 (Z30-Z275) |

| Surface structure | Large spangle, regular spangle, mini spangle, zero spangle |

| Surface treatment | Chromate, oil/unoil, bright finish, spangle, etc. |

| Processing Service | Welding, Punching, Cutting, Bending, Embossing |

| Depth of corrugated | 15mm – 18 mm or customizable |

| Pitch | 75mm – 78mm or customizable |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Production Process

The video documents the production process of roof panels from steel coils to corrugated steel sheets.

Characteristic

- Corrosion resistance: The zinc coating prevents moisture and oxygen from entering the steel, inhibiting rust. Excellent corrosion resistance.

- Durability: Withstands harsh weather, including wind, snow, rain, and hail, as well as UV exposure.

- Lightweight: Despite their high strength, they are relatively light, making them easy to transport and install. This reduces the load on the building structure.

- Cost-effectiveness: Cheaper than other roofing materials such as aluminum or copper. They have a long service life and low maintenance costs.

- Aesthetics: Different surface treatments, including regular glitter, minimal glitter, and no glitter, can also be painted or coated for visual appeal.

- Portability: They are easy to install and remove, making them a practical choice.

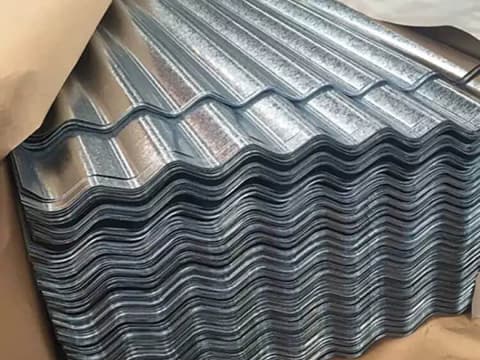

Galvanized Corrugated Metal Roofing Sheet Tile

heavy hot dipped gi roofing sheet

Use

1. Industrial Buildings: Roofs and walls of factories, warehouses, and workshops, providing basic corrosion protection.

2. Agricultural Buildings: Livestock farms (cattle sheds, chicken coops), greenhouses, and granary roofs, offering corrosion resistance and economical practicality.

3. Commercial Facilities: Roofs and enclosure systems for large-span buildings such as logistics warehouses, wholesale markets, and gymnasiums.

4. Residential Buildings: Self-built pitched roofs, awnings, and garage roofs, particularly common in rural areas and temporary residences.

5. Public Infrastructure: Outdoor facilities such as highway soundproofing walls, bus shelters, and train platform roofs.

6. Temporary Buildings: Construction site sheds, temporary warehouses, and disaster relief housing, due to their quick installation and reusability.

7. Other Applications: Non-construction applications such as ventilation ducts, appliance housings (such as refrigerator backs), and furniture base materials.

Roof Panel Interior Application

Farm road fence guardrail

Outdoor roof

GI Steel Roof Sheet Selection Recommendation Table

| Applications | Recommended substrate thickness (Thickness) | Recommended zinc coating code/thickness (Zinc Coating) | Key considerations |

| Large factory/warehouse roofs | 0.45mm – 0.60mm | Z100 – Z150 (100-150g/m²) | Wind load, snow load, span |

| Industrial plant walls | 0.40mm – 0.50mm | Z90 – Z120 (90-120g/m²) | Impact resistance and corrosion resistance requirements |

| Livestock and poultry house roofs | 0.45mm – 0.60mm | Z150 – Z200+ (150-200g/m²+) | Highly corrosive environments require a thicker zinc layer |

| Granaries and warehouses | 0.50mm – 0.70mm | Z120 – Z150 (120-150g/m²) | High strength requirements with moderate corrosion resistance |

| Logistics centers and markets | 0.50mm – 0.70mm | Z100 – Z150 (100-150g/m²) | Balance between strength and long-term durability |

| Noise barriers | 0.60mm – 0.80mm | Z120 – Z180 (120-180g/m²) | Must withstand wind loads and be maintenance-free |

| Self-built house roofs | 0.40mm – 0.50mm | Z90 – Z120 (90-120g/m²) | Aesthetically pleasing, economical, and sufficiently durable |

| Awnings and garages | 0.35mm – 0.45mm | Z60 – Z90 (60-90g/m²) | Cost-sensitive, low corrosion risk |

| Work sheds and prefabricated buildings | 0.35mm – 0.45mm | Z60 – Z90 (60-90g/m²) | Lowest cost, short-term use |

Galvanizing Process

1. Hot-Dip Galvanizing

The cleaned and activated steel coils are dipped into molten zinc (approximately 450°C). This reaction forms a durable zinc-iron alloy coating on the steel substrate.

Features

Thick coating, strong corrosion resistance, and durability of 20-50 years. The surface features a distinctive zinc flower pattern. The coating is metallurgically bonded to the steel substrate, making it extremely strong and resistant to peeling.

2. Electrogalvanizing

In an electrolytic cell, an electric current is applied to deposit zinc ions on the steel surface, forming a zinc coating. This is a purely physical deposition process.

Features

Thin coating, relatively weak corrosion resistance. It has a bright appearance and is easily susceptible to subsequent painting, such as color-coated steel coil. The coating is physically attached to the substrate, and the bonding strength is not as good as hot-dip galvanizing, making it more prone to micro-cracks when bent.

Hot-dip Zinc Roof Sheet 22 Gauge Galvanized Iron Sheet

1.2mm thickness Electrogalvanized iron sheet for roof

Commonly Used Board Shapes

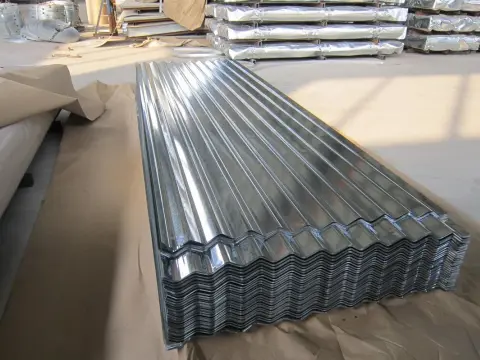

1. Conventional Corrugated Panels

This is the most traditional and classic panel type, featuring an undulating cross-section. Two common wave patterns are sinusoidal and trapezoidal, also known as zigzag waves. Connections are made with exposed nails. This offers the lowest cost.

2. Concealed Gusset Panels (Standing Seam System)

This is a high-end, mainstream system, representing higher technology and performance. The cross-section features high standing seams, either double or single. The panels are connected using a mechanical locking process, eliminating the need for screws.

3. Lap-Joint Panels

This is a compromise between corrugated panels and concealed gusset panels. The cross-section features high peaks on one side and low troughs on the other, often with specialized snap-on tongues and grooves. The connection is semi-concealed.

Surface Structure Type

Regular Spangle

Regular Spangle corrugated galvanised iron has a characteristic crystal pattern on the surface, which is a result of the hot-dip galvanizing process. This type is often used in general construction.

Minimal Spangle

Minimal Spangle boards have a finer, less noticeable crystal pattern. They are often used in applications that require a smoother surface finish.

No Spangle

No Spangle boards have a uniform, smooth surface without any crystal pattern. These are often used in applications that require a high-quality finish, such as construction projects.

Large Spangle Galvanized Steel Sheet

zero zinc flower galvanized coil

Regular Spangle galvanized coil

Commonly Used Zinc Layer of Galv Roof Panels

G90

G90 is a common grade of galvanised corrugated roofing sheets, indicating a zinc coating weight of 0.90 oz/ft2 (275 g/m2). This grade has excellent corrosion resistance and is widely used in construction.

G185

G185 sheets have a higher zinc coating weight of 1.85 oz/ft2 (564 g/m2) and have enhanced corrosion resistance. They are used in more demanding environments, such as coastal areas.

Z275

Z275 sheets have a zinc coating weight of 275 g/m2, similar to G90, and it complies with the EN 10346 standard. These sheets are commonly used in Europe and other regions to international standards.

G60

G60 sheets have a zinc coating weight of 0.60 oz/ft2 (183 g/m2). These materials are used in less demanding applications where moderate corrosion resistance is sufficient.

gi corrugated sheet

galvanised steel roof sheets

Color Coated Gi Roof Sheet

Color-Coated Galvanized Steel Overview

Color-coated galvanized steel sheet is actually the PPGI metal sheet (prepainted galvanized steel sheet). It’s a composite material made from galvanized sheet, which undergoes a surface degreasing chemical treatment and is then coated with weather-resistant PE, PVDF, HDP, and SMP coatings, followed by a baking cure. This composite material combines the strength of steel with the rust-resistant properties of a galvanized coating. Its rich color, corrosion resistance, and UV resistance make it widely used in building roofs, walls, and appliance housings. It’s an energy-efficient, aesthetically pleasing, and durable building material.

Popular Color

Common colors are sea blue, white, grey, and bright red. In addition to the commonly mentioned solid color roof, the most popular colors also include printed patterns, such as marble, camouflage, brick, and custom patterns.

Furthermore, different surface treatment processes can make the galvanised iron sheets look different in texture, such as 3D wood grain roof panels, wrinkle PPGI panels, and orange peel color-coated steel sheets.

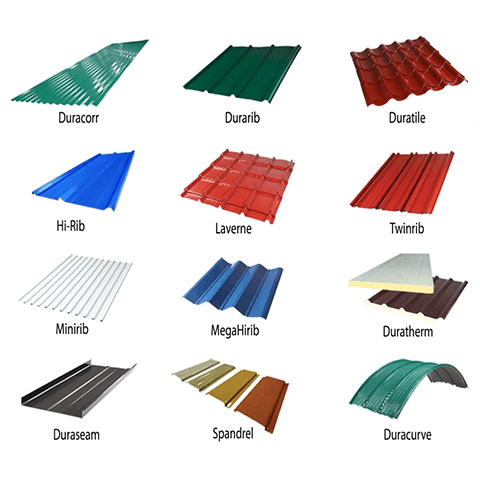

Most recommended roof panel shapes

Coated Roof Sheet Surface Types

Commonly Used Base Plates

1. Cold-Rolled Mild Steel Plate

This is the most common and economical base plate choice.

Common Grades

SPCC (Chinese Standard JIS), Q195/Q235 (Chinese National Standard), DX51D (European Standard EN).

Features

Excellent formability and strength, cost-effective. Its mechanical properties (such as yield strength and tensile strength) fully meet the requirements of most roofing applications.

2. Structural High-Strength Steel

Used when weight reduction or increased wind and snow loads are required.

Common Grades

S350GD, S550GD (European Standard EN), Q345 (Chinese National Standard), HSA340, HSA550 (high-strength grades).

Features

Higher yield strength and tensile strength are achieved through microalloying or special rolling processes. For the same design load, thinner plate can be used, saving material and transportation costs.

Roofing Sheets Plates Crimped Fence Plates

Corrugated Wave Galvanized Steel Plates

Difference Between SGCC and SPCC

- SGCC is a hot-dip galvanized steel plate with corrosion resistance, suitable for construction, home appliances and other fields.

- SPCC is a cold-rolled steel plate with a smooth surface, suitable for scenarios with high formability and high surface quality requirements.

SGCC meaning

A grade in the Japanese Industrial Standard (JIS G 3302), indicating Hot-Dip Galvanized Steel Sheet. It has a zinc layer on the surface and has good corrosion resistance.

- S: Steel.

- G: Galvanized.

- C: Cold Rolled.

- C: Commercial.

SPCC meaning

A grade in the Japanese Industrial Standard (JIS G 3141), indicating Cold Rolled Steel Sheet. There is no zinc coating on the surface and it can be painted and electroplated.

- S: Steel.

- P: Plate.

- C: Cold Rolled.

- C: Commercial.

SGCC vs. SPCC comparison table

| Features | SGCC | SPCC |

| Standards | JIS G 3302 | JIS G 3141 |

| Surface treatment | Hot-dip galvanizing, with zinc layer protection | No coating, smooth surface |

| Corrosion resistance | High (due to zinc layer protection) | Low (subsequent painting or electroplating required) |

| Mechanical properties | Suitable for general forming and processing | High formability, suitable for complex molding |

| Surface quality | Ordinary zinc flower, small zinc flower, no zinc flower | High surface quality, suitable for spraying, electroplating |

| Main uses | Construction, home appliances, auto parts | Automobile body, electrical housing, furniture |

| Price | Higher (due to galvanizing process) | Low (no coating) |

SGCC extended grades

- SGCC Z27: The zinc coating weight is 275 g/m² (total weight on both sides).

- SGCC Z18: Galvanized coating weight 180 g/m² (total weight on both sides).

- SGCC Z60: The zinc coating weight is 60 g/m² (total weight on both sides).

SPCC extended grades

- SPCC-SD: Standard surface quality.

- SPCC-SB: High surface quality, suitable for spraying.

- SPCC-SS: Highest surface quality, suitable for electroplating.

Recommended scene selection

Choose SGCC

Corrosion resistance is required (e.g. outdoor buildings, appliance housings) and high surface quality is not required.

Choose SPCC

High surface quality and high formability are required (such as automobile bodies, electrical appliance housings), and subsequent painting or electroplating treatment is required.

galvanized corrugated

Corrugated Galvanized Steel Sheet

Galvanized roofing sheet price

The price of zinc galvanized roofing sheet varies depending on factors such as thickness, width, galvanizing weight, and market conditions. According to the latest data, the price range is $1.50 to $5.00 per square foot. Pre-painted and color-coated sheets are usually more expensive because of the paint application step involved.

Factors affecting the price

- Thickness: Thicker sheets are more expensive because of the increased material cost.

- Galvanizing weight: Sheets with higher galvanizing weight (such as G185) are more expensive, but have better corrosion resistance.

- Surface treatment: The price of pre-painted and color-coated sheets is higher than that of ordinary galvanized sheets.

- Market demand: Prices may fluctuate based on market supply and demand dynamics. For example, galvanized roofing sheet price in nigeria, galvanized roofing sheet price in ghana, gi roofing sheet price in sri lanka are different.

If you want to know the galv corrugated roof sheets price of the day, you can ask our professional technicians.

Export Package

We use waterproof kraft paper packaging inside and thin metal plate outside, plus 6 pieces of rope to tie it.

Inner waterproof kraft paper packaging

Outer packaging of roof panels

Cold rolled EGI sheet shipped to India

Galvanised Steel Roofing Sheet Supplier- Wanzhi Steel

Whether you are building a new house, commercial facility, or agricultural shed, galvanized metal roof are a reliable and long-lasting roofing solution. Choosing Wanzhi Steel means choosing quality and trust. Our galvanized roofing sheets offer exceptional weather resistance and durability, providing long-lasting protection for your building. Contact us for a personalized quote and technical proposal.

Why Choose Us?

- Production Strength: We have two fully automatic continuous hot-dip galvanizing production lines to ensure uniform and firm adhesion of the galvanized layer.

- Quality Assurance: We strictly adhere to international standards to ensure consistent mechanical and corrosion resistance in each roll of steel sheet.

- Supply Chain Advantages: Integrated production from raw materials to finished products, with massive production capacity and fast delivery cycles.

- Customization: We can flexibly customize the zinc coating, specifications, roll weight, and packaging to meet project requirements.

- Price Competitiveness: Large-scale production offers cost advantages and exceptional value for money.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com.

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of perforated galvanized sheet, Steel Grating Plate, perforated aluminum sheets, Galvanised Mesh Panels, Welded Wire Fabric, Stainless Mesh Sheet for 14 years, providing color coating, welding, PVC coating and other services, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

- Aluminum Fence Panel

- WPC Fence Panels

- Steel Reinforcement Mesh

- Galvanized Concrete Mesh

- Galvanized expanded metal mesh

- Brick reinforcing mesh

- Steel Reinforcement Bar

- Galvanized Barbed Wire

- Black Annealed Wire

- Construction Binding Wire

- Steel Wire Rod

- Galvanized Razor Wire

- Low Carbon Steel Wire

- Galvanized Concertina Wire For Sale

- Steel Grating Plate

- Wire Mesh For Concrete Slab

- 430 stainless steel

- HRB400 Steel

- Q235 Steel

- DX51D