Galvanized Bolts

Coat thickness: 50-65μm

Size: M3 M4 M6 M8 M10 M11 M30 M42 M54

Grade: 4.6/4.8/5.6/5.8/8.8/ 10.9/ 12.9

Transportation: By sea or by land

Galvanized Bolts

Galvanized bolts are steel bolts coated with a layer of zinc to prevent corrosion. With excellent corrosion resistance and durability, they are essential fasteners widely used in construction, automobiles, machinery, and infrastructure. The galvanizing process prevents steel bolts from rusting and prolongs their service life in harsh environments. Wanzhi Steel stocks a large number of regular-sized galvanized bolts with different steel grades and accepts customization of size and color. If you are interested, please contact us.

a325 galvanized bolts

zinc yellow blots

Black coated galvanized bolts

Galvanized Bolts Specification

| Item | Galvanized Bolts |

| Origin | Hebei, China |

| material | Stainless Steel, Alloy Steel, Medium Carbon Steel, High Carbon Steel |

| Head type | External hexagon, L, J, U, T, etc. |

| The total length | 3/8(mm), Other customizable |

| Service | OEM/ ODM |

| Package | Small Boxes, Plastic Bags, Bulk in Cartons, Pallets |

| MOQ | 3 tons |

| Delivery time | 15-22 Days |

| Payment Methods | TT 30% prepaid, 70% paid before shipment/50% prepaid/full payment |

GAL L Type Foundation Anchor Bolt

concrete galvanized anchor bolts for sale

Weight Calculation Formula

- Theoretical weight: W (g) = 0.0068 × thread diameter² × total length (mm)

- Actual weight: W (g) = theoretical weight × 0.9 (thread weight reduction 10%)

Grades of Galvanized Bolts

- Grade 4.6: Characterized by low carbon content, so relatively low strength.

- Grade 5.6: Medium strength, medium carbon steel content but low hardness.

- Grade 5.8: Medium strength medium carbon steel, but with higher ductility.

- Grade 8.8: Made of medium carbon steel, higher strength than grade 4.6 fasteners.

- Grade 10.9: Made of higher strength alloy steel. The strongest and most common carbon steel.

- Grade 12.9: It is a hard and strong steel. Used in situations where high strength, high carbon steel is required.

galvanized carriage-u-eye bolts

Foundation Anchor Bolt LJ Type Hook bolt

The mMeaning of the Characters Indicating Bolts

What do the characters in Din 6921/DIN 933 Grade 10.9 Hex Flange M16/M30/M12×50 Hot Dipped Galvanized Bolt mean?

- Din: German Industrial Standard (Deutsches Institut für Normung).

- 6921: Standard number, specifically refers to the size and tolerance requirements of hexagonal flange bolts.

- 933: Standard number, specifically for Hexagon Head Bolt with Full Thread.

- Grade 10.9: The number “10” indicates that the tensile strength of the bolt is 1000 MPa. The number “9” indicates that the yield strength ratio is 0.9 (yield strength = 1000×0.9=900 MPa).

- Hex: Hexagonal Head, which needs to be installed with an open-end wrench.

- Flange: With flange surface (integrated gasket), anti-loosening function, reducing the pressure on the connection parts.

- “M”: Metric Thread Standard (Metric Thread).

- 16/30/12: Nominal diameter of the thread (unit: mm), bolts with a diameter of 16mm/30mm/12mm.

- 50: Total length (mm, including head).

- Hot Dipped Galvanized: The Surface treatment is hot-dip galvanized.

A490 screw head diameter

galvanized steel bolts

galvanized anchor bolts supplier

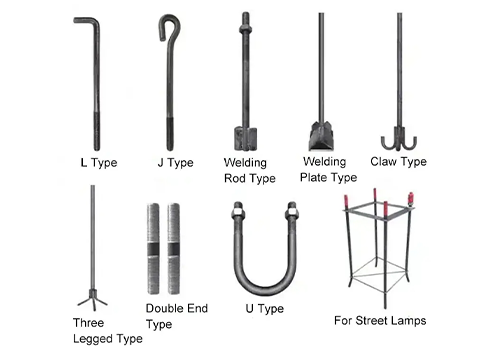

Shape Classification

1. According to the shape of the thread, it can be divided into triangle, trapezoid, zigzag, and arc thread.

2. The direction of rotation can be divided into left-handed and right-handed.

3. The number of spiral lines can be divided into single-line and multi-line.

4. According to the shape of the head, it can be divided into:

- Hexagonal head galvanized bolt: six-sided head, used with a wrench.

- Carriage bolt: round head, square neck, smooth round head, anti-rotation square neck.

- Eyebolt: Ring head for cable/chain.

- U-bolt: As the name suggests, the shape is U-shaped.

- J-bolt: J-shaped end, can be embedded in concrete.

- T-bolt (T-slot bolt): T-shaped head, can slide into the groove.

Head diameter-length table

galv eye & u bolts and nuts

Bolt Grade System – International Standard

1. International standards (ISO) and Chinese national standards (GB)

| Grade mark | Tensile strength | Yield strength |

| 4.6 | 400 | 240 |

| 4.8 | 420 | 336 |

| 5.8 | 500 | 400 |

| 6.8 | 600 | 480 |

| 8.8 | 800 | 640 |

| 10.9 | 1000 | 900 |

| 12.9 | 1200 | 1080 |

Note: Grade 8.8 and above are called high-strength bolts, which need to be used with nuts and have higher preload and safety.

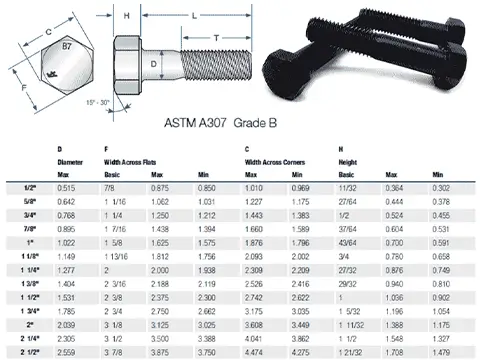

2. American Society for Testing and Materials Grading System (ASTM)

Classification based on steel chemical composition and mechanical properties:

- Grade A Steel: Low strength, low carbon steel.

- Grade B Steel: Medium strength, medium carbon steel.

- Grade C Steel: High strength, high carbon steel.

3. Society of Automotive Engineers Grading System (SAE System)

Classification based on steel strength and hardness:

- Grade 2 Steel: Refers to low carbon steel with lower strength. Best suited for general applications requiring low to medium strength.

4 inch a325 a490 M8 hot dip galvanized fasteners

- Grade 5 Steel: Medium strength, medium carbon steel. Again, best suited for applications with medium strength and hardness.

- Grade 8 Steel: For situations where high strength and hardness steel are required.

4. ASTM Standards

| Grade Mark | Tensile Strength (ksi) | Equivalent ISO grade | Galvanizing suitability |

| ASTM A307 | 60 ksi (414 MPa) | ≈4.6 | Ordinary hot-dip galvanized bolts |

| ASTM A325 | 120-150 ksi (827-1034 MPa) | ≈8.8 | Specialized in structural engineering |

| ASTM A490 | 150-173 ksi (1034-1193 MPa) | ≈10.9 | Requires a special coating process |

Advantages of Galvanized Bolts

- Corrosion resistance: In wet/salty environments, the service life is 5-10 times longer than uncoated bolts. The zinc layer is dense and can resist acid rain, salt spray, etc.

- Economical: It has a similar anti-rust effect as stainless steel, but the price is much lower than stainless steel.

- High strength: Maintain structural integrity under heavy loads and have an outstanding fastening effect.

- Durability: The substrate protected by a hot-dip galvanized zinc layer can have a service life of up to 15 years without rust.

- Stability: The coating evenly covers the bolts, enhancing the overall corrosion resistance, and the bright silver finish is suitable for visible structures.

J,U,anchor,eye,carriage,hex,coach,square galvanized bolts

Grade Size Table

Application

1. Recommended applications at different grades

- Grade 4.6: general furniture, light structures.

- Grade 4.8: indoor light-load connections (such as furniture assembly, electrical appliance fixing).

- Grade 5.8: mechanical equipment, ordinary buildings.

- Grade 8.8: the largest market demand. Suitable for most projects such as bridge guardrails, power towers, and building steel structures.

- Grade 10.9: the most high-strength application options, such as glass curtain walls and high-speed railway tracks.

- Grade 12.9: heavy machinery, excavators, large steel structures.

Note: Stainless steel A2-70/A4-80 is recommended for grades 10.9 and above.

stainless nut and blots

2. Recommended applications by category

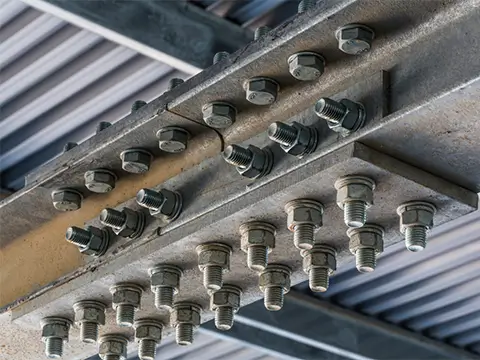

- Hexagonal galvanized bolts: building beams, mechanical assembly.

- Carriage bolts: wooden structures, fences, trailers.

- Eyebolts: rigging, marine equipment, suspension systems.

- U-bolts: for pipe/round rod clamping.

- J-bolts: foundation anchoring, road signs.

- T-bolts: machine tools, aluminum frames.

3. Main application industries

- Building and Infrastructure: Steel frames, bridges, and roofs to resist weather damage.

- Automotive and Transportation: Chassis components, exhaust systems (to withstand road salt).

- Machinery and Equipment: Agricultural machinery, conveyor systems (durable under friction).

- Electrical and Telecommunications: Transmission towers, utility poles (long-term outdoor use).

- Marine and Offshore: Docks, shipbuilding (resistance to saltwater corrosion).

Glass curtain wall fastening

Dock bolts

Transmission tower bolts

Manufacturing Process

1. Production steps

- Cleaning – Bolts are degreased and pickled to remove impurities.

- Galvanizing -1) Hot dip galvanizing: immersed in a molten zinc bath, the coating is 50-100μm thicker.

2) Electrogalvanizing: electrolytic principle, the coating is 3-5μm thinner and has high precision.

- Cooling and inspection – quality inspection of bolt surface, size, corrosion resistance, impact resistance, coating thickness, etc.

2. Typical galvanizing processes for each grade

- Grade 4.8: Electrogalvanizing (conventional rust prevention).

- Grade 6.8: Hot-dip galvanizing (outdoor use).

- Grade 8.8: Hot-dip galvanizing + passivation treatment.

- Grade 10.9: Dacromet coating (high corrosion protection).

- Grade 12.9: Usually not galvanized (risk of hydrogen embrittlement).

3. Applicable grades of three types of galv bolts

1) Electrogalvanized bolts: Applicable to grades 4.8, 5.8, and 6.8. Low cost, general corrosion resistance, salt spray test 72-200 hours.

2) Hot-dip galvanized bolts: Applicable to grade 8.8 and below (high grade needs to control hydrogen embrittlement), fog test 1000+ hours, suitable for outdoor projects.

3) Mechanically galvanized bolts: Applicable to grade 8.8 and below, no risk of hydrogen embrittlement, suitable for automotive parts.

hot dipped galvanized bolts and nuts

galvanized and black carriage-u-eye bolts

Galvanized Bolts Price

First, the zinc layer thickness, galvanizing process, bolt grade, and size will directly affect the price. Second, the order volume will also affect the unit price.

The reference prices are as follows:

- M6-M12 hot-dip galvanized bolts: $0.10-1.50 per piece (lower bulk price).

- Electro-galvanized bolts: 20-30% cheaper than hot-dip galvanizing.

The above are approximate prices. Please contact our professional technicians for today’s prices.

Popular surface treatments

Reference table of galvanized bolt weights (unit: grams per bolt)

| Size (M) | Lengt (mm) | Theoretical Weight (g) | Actual Weight (g) | Weight per 1000 pieces (kg) |

| M6 | 20 | 8.2 | 7.4 | 7.4 |

| 30 | 12.3 | 11.1 | 11.1 | |

| M8 | 30 | 23.6 | 21.2 | 21.2 |

| 40 | 31.5 | 28.4 | 28.4 | |

| M10 | 40 | 49.3 | 44.4 | 44.4 |

| 50 | 61.6 | 55.4 | 55.4 | |

| M12 | 50 | 85.1 | 76.6 | 76.6 |

| 60 | 102.1 | 91.9 | 91.9 | |

| M16 | 60 | 181.2 | 163.1 | 163.1 |

| 80 | 241.6 | 217.4 | 217.4 | |

| M20 | 80 | 378.5 | 340.7 | 340.7 |

| 100 | 473.1 | 425.8 | 425.8 | |

| M24 | 100 | 681.3 | 613.2 | 613.2 |

| 120 | 817.6 | 735.8 | 735.8 | |

| M30 | 120 | 1276.4 | 1148.8 | 1148.8 |

| 150 | 1595.5 | 1436.0 | 1436.0 |

Packaging Methods of GI bolts

① Small-volume retail packaging: plastic bag (100-500 pieces) + carton. With size/grade labels for easy identification.

② Wooden box + waterproof packaging: 5,000-50,000 pieces, palletized to prevent moisture damage.

③ Customized OEM, ODM packaging: LOGO-printed packaging boxes or bags, VCI (vapor corrosion inhibitor) bags, suitable for long-term storage.

package of galv bolts

3 8 galvanized carriage bolts package

Why Choose Wanzhi Steel

- High-quality manufacturing: Ours Bolts, screws, nuts, washers and rivets comply with GB/JIS/DIN/ANSI/ASME/BS standards and ISO: 9001 certification.

- Full grade coverage: Custom production from 4.6 to 12.9 grade, all standard and metric sizes (#4–1″). Custom coating includes being zinc plating (BZP) and black oxide. Non-standard processing can be carried out according to drawings and samples.

- Professional equipment: Multi-station head machines 60 units, automatic gear hobbing machines 80 units, automatic capping machines 50 units, automatic tapping machines 42 units.

- Test report: Provide salt spray test, third-party certification of mechanical properties, salt spray test ensures 1,000+ hours of rust resistance.

- Competitive price and fast delivery: Factory-direct price without middlemen. Global shipping FOB, CIF, EXW options.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of anchor eye bolts, stainless steel foundation bolts, stainless steel toggle bolts, Duplex nails, galvanized anchor bolts, Common nails, stainless steel threaded rods, Stainless Steel Anchor Bolts, and chemical anchor bolts for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message