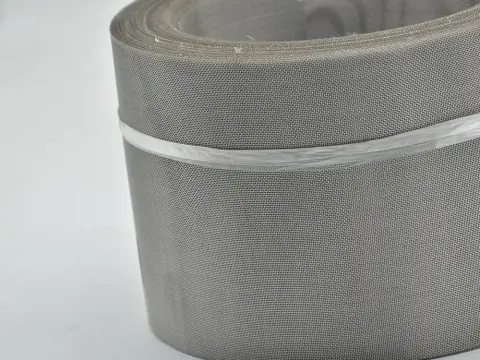

Fine Mesh Screen

“Fine mesh screen” is a “fine screen” or “selector”. It is a device or tool with fine mesh or sieve holes, which can effectively screen out fine particles or substances, and also play a role of isolation and protection, such as metal screens. Wanzhi Steel specializes in the production of high-quality stainless steel screens, galvanized wire screens, aluminum fly wire mesh, and alloy wire screens. Such as 100 mesh screen, 400 mesh, 300 micron mesh, and 500 micron stainless steel mesh…The aperture and wire diameter can be customized, and a wide range of specifications are available. You are welcome to send us the size for consultation.

ultra fine metal mesh

steel window screen

fine steel mesh

Specification

| Item | Fine mesh screen |

| Place of Origin | Hebei, China |

| Delivery Time | 10-18 days |

| Standard | AISI, ASTM, DIN, JIS, GB, EN |

| Material | Stainless steel Wire(Galvanized wire) |

| Grade | 304, 304L, 316, 316L, 310s, 904L, 430, etc |

| Type | Wire Cloth, Metal Mesh |

| Hole Size Range | 1 – 3500mesh |

| Wire Diameter | 0.02 – 6.30mm |

| Width | ≤2000 mm |

| Length | Customizable |

| Weave Style | Plain Weave, Twill Weave, Dutch Weave, Multiplex Weave |

| Processing Service | Welding, Cutting, Punching |

| Shape | Can be cut into round or square shapes |

| Function | Screening\separation\sorting\sieving\Grading |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 240rolls/pieces, 5 tons |

| Transportation | By land, by sea |

What is fine mesh screen?

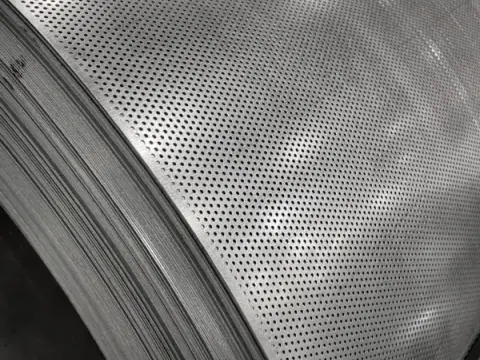

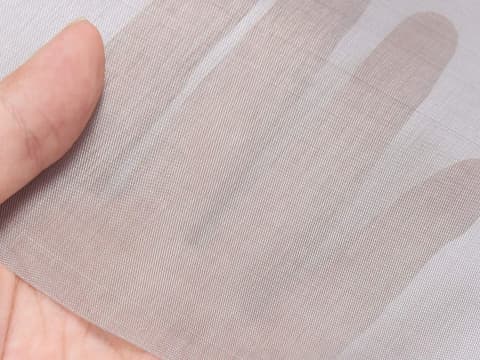

The fine mesh screen is crafted from premium 304-grade stainless steel, renowned for its durability and resistance to rust. Precision is evident in its design, boasting 150 wires per linear inch, resulting in a total of 22,500 wires per square inch. Usually, there are two forms: woven mesh or welded mesh. There are also perforated mesh screens such as Black Powder Coated Carbon Steel Perforated Metal Mesh Screen.

perforated stainless steel screen

Stainless Steel Crimped Screen Mesh sheet

perforated stainless steel mesh

Features of Fine mesh screen

1. Fine mesh: It can screen out tiny particles.

2. Efficient screening: In addition, it can complete screening tasks quickly and accurately.

3. Durability: A fine mesh sieve is usually made of strong and durable materials, and can be used for a long time without being easily damaged.

In addition, the stainless steel woven mesh is an ideal material for screening/sieving, it has the following excellent properties:

1) Long-term performance.

2) Heat resistance.

3) Ease of fabrication.

4) Cleanability and hygiene properties.

5) Strength.

6) Life cycle costing.

7) Low environmental impact.

Application of Fine Mesh Screen

1. Food and beverage, pharmaceutical, and automotive to filter, sift, size, or ventilate.

2. Pump protection, irrigation, and primary treatment in drinking water plants, such as heavy-duty stainless steel screens.

3. Fly screen, insect screen, mosquito net for windows, bug screen.

4. Isolate dust, debris, and environmental particles, decorative metal screen mesh.

5. Bird mesh, garden barriers, pond leaf cover, Net cover, vegetable tent.

black metal screen mesh

heavy duty metal screen mesh

304 stainless steel mesh screen

Why use fine mesh screen?

1. In daily life, we need to prevent mosquitoes, insects, and air debris such as catkins, fiber hair, leaves, dust, etc., which are inseparable from metal fine mesh screens. They are safe enough and effective enough.

2. Furthermore, they are harder than plastic screens, so there is no need to worry about frequent replacement due to damage.

3. On the other hand, in many fields, such as chemical industry, mining, food processing, etc., it is necessary to filter plastics, latex, processing waste, etc., so fine screens also play an important role. They can ensure the quality and purity of the product, and remove impurities and particles that do not meet the requirements through screening.

4. In the field of experimental scientific research, it is an indispensable equipment material. Because their mesh size ranges from 5 mm to 80 microns, it is irreplaceable for us.

200 micron stainless steel mesh

“200-micron stainless steel mesh” usually refers to a stainless steel mesh with a pore size of 200 microns (ie 0.2 mm). Commonly used stainless steel materials include 201, 202, SUS304 (also known as 304), 304L, 316, 316L, and 310S.

Among them, materials above 304 have high acid and alkali resistance, corrosion resistance, and high-temperature resistance, so they are more suitable for use in harsh environments.

For example, in food processing, pharmaceuticals, and water treatment, in laboratories and scientific research, 200-micron stainless steel mesh can be used to make filters, sample filters, and other equipment.

steel security mesh

fine strainer

Sieves

Detailed Explanation of Mesh, Mesh Count, and Micron Size

What is Mesh Count?

In the stainless steel wire mesh industry, “mesh” is a common specification parameter, which indicates the number of mesh holes per square inch (about 6.45 square centimeters). However, it should be noted that there is not a strict linear relationship between mesh number and pore size, because different weaving methods and wire diameters will affect the final pore size. Then, in general, a 200-mesh stainless steel wire mesh roughly corresponds to a pore size of about 200 microns.

Important terms

1. Mesh Count and Micron Size are some of the important terms in the wire mesh industry. The Mesh count is calculated by the number of holes in an inch of mesh, so the smaller the woven holes, the bigger the number of holes.

2. The Micron Size refers to the size of the holes measured in microns. (The term micron is actually a commonly used shorthand for micrometer. )

3. In order to make it easier for people to understand the number of holes in the wire mesh, these two specifications are usually used together. This is the key component of specifying the wire mesh.

The Mesh Count determines the filtering performance and function of the wire mesh.

More intuitive expression:

stainless steel screen

stainless steel fly screen

24 mesh stainless steel screen

How fine is 400 mesh?

| Mesh | Inches | Microns | Millimeters |

| 170 | 0.0035 | 88 | 0.088 |

| 200 | 0.0029 | 74 | 0.074 |

| 230 | 0.0024 | 63 | 0.063 |

| 270 | 0.0021 | 53 | 0.053 |

| 325 | 0.0017 | 44 | 0.044 |

| 400 | 0.0015 | 37 | 0.037 |

The table above is for your reference, for the other 24 lines please see – Galvanized Wire Mesh Screen.

Which mesh is finer, 200 or 400?

100 microns is finer than 600 microns. This value measures the holes in the mesh in microns, with a higher number meaning a larger hole. 100 micron mesh holes are 0.003925″ compared to 600 micron mesh which is 0.023550″. 400 micron mesh has 0.015700” holes, and 200 micron mesh has 0.007850″ holes.

316 stainless steel mesh screen

fine mesh metal screen

galvanized woven wire mesh roll

What is the difference between a fine screen and a coarse screen?

1. Fine metal mesh screen

The aperture of the fine metal mesh is smaller, usually less than 25mm, and is used for fine screening to remove smaller impurities.

In the field of papermaking, the pulp screens for fine screening are all slot screens, and the screen slot can be less than 0.2mm.

Characteristics: It has a good effect on removing three-dimensional impurities, thin sheets, and other impurities, and even has a good removal effect on adhesive substances.

2. Coarse mesh screen

The aperture of the coarse sieves is larger, usually greater than 25mm, and is mainly used for preliminary screening to remove larger impurities. In the fields of papermaking, wastewater treatment, etc., the coarse screen machine is generally a hole screen with an aperture of about 1.3~2.0mm.

Characteristics: It is mainly used for pre-screening to quickly remove large-sized impurities and non-compliant particles to create good conditions for subsequent processing.

stainless steel wire mesh cloth

stainless steel fly screen mesh suppliers

Galvanized Mesh Screen Packaging

Get the price of the Fine Mesh Screen from Wanzhi Steel

1. Advanced production equipment: equipped with fully automatic laser welding production line and ultra-precision weaving system, supporting 304/316/430 stainless steel, galvanized wire, aluminum wire and other processing.

2. Strict quality control system: adopting online detection and salt spray test, passing ISO9001/14001 dual certification, ensuring military-grade quality.

3. Large-scale customization capability: can produce 3m×15m ultra-wide screens, provide special-shaped cutting technology, and meet the requirements of harsh working conditions such as petroleum and photovoltaics.

4. Industry-leading delivery: conventional products are shipped quickly in 3-7 days, with an annual production capacity of 500,000 square meters, serving global customer projects.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Stainless steel mesh roll, 1 4 galvanized screens, Galvanized Wire Mesh Roll, 304/316 SS steel mesh screen, Stainless Steel Mesh Screen, Insect screens for windows, Galvanized Steel Hardware Cloth, 60 micron stainless steel mesh, and 55 micron fine mesh screen for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message