Duplex Nails

Duplex Nails (also called double headed nails or Scaffold nails) are specialized fasteners that have two heads on the shank. The primary head is used to secure the material, while the secondary head is easily removed, making them ideal for temporary construction, scaffolding, and concrete formwork. Duplex nails combine strength and versatility. They can be installed and removed quickly without causing damage. Wanzhi Steel stocks a large number of common specifications of duplex nails with polished and galvanized finishes for you to choose from. Welcome to contact us~

Building Construction nails

Galvanized and annealed surfaces

60mm hot dipped galvanized duplex nail

Duplex Nails Specification

| Item | Duplex Nails/Two-Head Nails |

| Place of origin | Hebei, China |

| Material | Low carton steel(Q195, Q235) |

| Head | Flat, Double head |

| Shank | Smooth, Ring, Spiral |

| Point | Sharp diamond point |

| Length | 6d-20d, 53.5-116.3 mm, 2″-4-1/2″, 30D |

| Head diameter | 2 mm-12 mm |

| Shank diameter | BWG13 – BWG6(2.40 mm-5.16 mm) |

| Finish | Polished, E.G., H.D.G |

| Standard | ASTM/JIS/DIN/GB/EN/AISI |

| MOQ | 3 Tons |

| Key words | Polished nails, nail for building construction, common wire nails |

| Character | Duplex common nail has a toughness curvature ≥90°, smooth surface of E.G. or Polished, Sharp point. |

| Payment Methods | TT 30% prepaid, 70% paid before shipment |

| Delivery Time | 15-18 days |

The main advantages of stud nails

① Reusable: The secondary nail head is easy to remove without damaging the material. It can be reused 5-10 times, reducing the cost of temporary construction.

② Enhanced safety: Prevents over-penetration of scaffolding and ensures structural stability. Minimizes wood cracking compared to standard nails.

③ Corrosion resistance: Hot-dip galvanizing (HDG) (galvanizing layer thickness: 50-80μm) is usually used for outdoor use. Stainless steel (304/316) can be selected for coastal areas or chemical environments.

④ High load-bearing capacity: Made of high carbon steel (tensile strength: 550-650 MPa). Supports heavy-duty applications such as concrete formwork support.

Low Carbon Steel Duplex Head Nails

Electro Double Head Nail Polished

16D Bright Duplex Head Nails

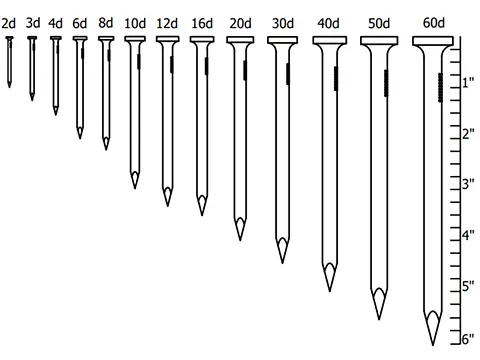

Size Types

Features of each size

6D: Short and thin, suitable for limited space or thin plate fixing. Easy to disassemble, suitable for frequent adjustment scenes.

8D: Common specifications on construction sites, suitable for most medium-thick wood or metal brackets.

10D: Thicker than 6D/8D, suitable for higher load requirements and higher stability.

16D: Long (3.5 inches) and sturdy, providing deep fixing, suitable for medium and large projects.

20D: The thickest diameter provides the strongest fixing force. Suitable for long-term exposure to outdoor or high-stress environments.

30D: The largest specification, suitable for extreme working conditions, suitable for heavy-duty applications, galvanized or coated surfaces.

Note: The length of the nail is indicated by the letter “D”. D is the name of the British penny, so the length of the nail is in “penny”.

Different Lengths and Wire Gauges

Each size specification

| Size | Gague | Length overall | LengthunderLower Head | Diam top head | Distance between head | Approx.Number per.lb |

| 6D | 11-1/2 | 2-7/64 | 1-3/4 | 3/16 | 1/4 | 156 |

| 8D | 9 | 2-5/8 | 2-1/4 | 15/64 | 1/4 | 90 |

| 10D | 8 | 3-3/16 | 2-3/4 | 1/4 | 5/16 | 59 |

| 16D | 7 | 3-1/2 | 3 | 9/32 | 3/8 | 45 |

| 20D | 6 | 4-1/64 | 3-1/2 | 5/16 | 3/8 | 28 |

| 30D | 5 | 4-37/64 | 4 | 21/64 | 7/16 | 22 |

Types of Duplex Nails

① Standard duplex nails: Made of hot-dip galvanized steel, common specifications, smooth nail shank.

② Stainless steel duplex nails: Made of 304, 316, or other stainless steel.

③ Ring handle duplex head nails: With barbed handle design to enhance grip.

④ Spiral duplex nails: Twisted shank, stronger pull-out resistance.

Wooden frame application

Application

Uses of different shank lengths

2″ (50mm): Screw-shank nails are used for agricultural or small applications such as light pallets, temporary fences, livestock fences, etc.

3″ (75mm): Scaffolding, concrete forms fixing (3-inch to 4-inch hot-dip galvanized nails).

4″ (100mm): 4-inch to 6-inch ring-shank nails are used for Heavy framework, industrial bracing.

6″ (150mm): Bridge construction, large scaffolding, heavy applications.

6D: Small wooden structures such as wooden pallets, small furniture, lightweight wood, decorative strips, and cable duct fixings.

8D: Fixing concrete forms, wall forms, scaffolding crossbars or diagonal braces.

10D: Fixing thicker concrete forms or load-bearing structures, temporarily fixing large equipment bases or brackets.

16D: Fixing scaffolding main nodes, temporary fixing of bridge pier forms or support beams.

20D: Large bridge forms, high-rise building wall fixings.

30D: Commercial complexes, large-span buildings, heavy machinery, or steel structure supports.

Scaffolding inclined beam

Binding wooden frame

Beehive fixing

Different types of applications

Standard duplex nails: used in ordinary scaffolding, wood framework.

Stainless steel duplex nails: used in chloride environments such as marine construction, chemical plants.

Ring handle duplex nails: often used in high vibration areas (e.g., trailer floors, punching machines).

Spiral duplex nails: used in permanent but removable structures (e.g., mobile stages, livestock pens).

Applications in various fields

1. Building scaffolding and concrete formwork

1) Temporary structure construction: In scaffolding, formwork, or supporting structures, studs can be quickly fixed and easily pulled out, and reused.

2) Concrete pouring: When fixing the formwork, studs can ensure that the formwork is stable and prevent concrete leakage. The formwork will not be damaged during disassembly.

2. Woodworking and furniture making

Temporary fixing: When assembling furniture or wood products, studs can be used for temporary fixing to facilitate the adjustment of angles or positions. They are also suitable for permanent connections.

3. Other scenarios

1) Beehive production: In the design of beehives for trapping wild bees, the studs can be easily disassembled and reused after the bee colony is removed.

2) Insulator fixing: In some power equipment, studs are used to fix insulators so that the insulating material will not be damaged when they need to be disassembled for maintenance.

Temporary fence fixing

Trailer Floor

Wooden furniture manufacturing

Manufacturing process

① Wire drawing: Low carbon steel rod is drawn into precise diameter (2.8-5.0mm).

② Cutting and upsetting: The CNC machine cuts the wire to the required length and forms two upsetting heads.

③ Surface treatment: Polishing, hot-dip galvanizing, or electro-galvanizing for corrosion resistance.

④ Quality inspection: Length measurement (±0.5mm), upsetting calibration. Coating test (salt spray test) is carried out.

Wanzhi Duplex Nail Export Case

Exported 88 tons of duplex to Iran

Wanzhi Steel shipped 88 tons of 30mm, 40mm, and 50mm double-head nails to Iran.

Wanzhi Steel Quality Control Standards

1. Tensile strength: ASTM E8, ≥550 MPa.

2. Coating thickness: Magnetometer, ≥50μm (HDG).

3. Salt spray resistance: ASTM B117, no rust after 500 hours.

4. Head shear strength: ISO 9001, can withstand 500N force.

Metal Wire Rod Wanzhi facroty

Wanzhi Quality Inspection

Length measurement

Packaging

Options

1. Cartons: 1–5 kg, for retail/DIY store channels.

2. Steel drums: 25–50 kg, for building contractors.

3. Bulk bags: 500–1,000 kg, for industrial projects.

4. Label: Contains size, type, coating type, and batch number.

Export specifications

1) 1lb/box 8box.carton.

2) 5lb/box 6box/carton.

3) 50lb/box , 48 box/pallet.

4) 30lb/pail ,48 pail/pallet.

5) 50lb/box,48 box/pallet.

or according to customers’ request.

16D Duplex Nails Plastic box packaging

Carton package

BWG 11×2-1/2″ 1lb HDG nails

Why choose Wanzhi Steel?

① Customized size: 1 inch to 6 inches (special lengths available upon request).

② Quality assurance: Accept third-party quality inspection. 100% batch test consistency.

③ Fast delivery: 15-18 days production cycle (monthly capacity of more than 1,800 tons).

④ Price competitiveness: Factory direct sales, discounts for bulk or large orders.

Duplex nails are the ultimate choice for temporary and reusable structures, combining strength, safety, and cost-effectiveness.

Get samples or a bulk quote! Chat with Us Online,

or send an email to: info03@wanzhisteel.com

Wanzhi Steel is an ISO 9001-certified steel factory located in Hebei, China. It has been specializing in the production of Duplex nails, Anti bird spike, Coil Nails, Galvanized spikes, Common nails, Anti-climb Spikes, and Roofing Nail for 14 years, with a monthly output of 1,800 tons. With high-quality products and good services, its products have been exported to more than 120 countries around the world.

Leave Us A Message